Adjustable Power Supply v18.08

In Progress

Arduino code for voltage sensing and control

Arduino code is hosted here. This code is far from finalized and represent only one of many possible design approaches. Post as many variations or improvements as you can as long as they have advantages.

Next steps: - implement SPI to control digital potentiometer

Design buck/boost converter module

For affordable buck-boost that can change voltage by a factor of five, high frequencies are needed to reduce inductor size. The Arduino has a limited PWM frequency (less than 100 kHz?).

Volt-second balance on the inductor means that the average voltage across it over one switching cycle is zero

Discontinuous mode is when current through the output inductor is zero for part of the switching cycle

Next steps: - simulate main circuit - design PCB - research microcontroller options for voltage control and display

Figure out ways to salvage or build transformers

Investigate ways to use high frequency for more efficiency in power transformation as well as smaller inductors.

With new Silicon Carbide MOSFET technology, maybe feasible to use flyback transformer at high frequency as described here.

A flyback transformer could more compact and cheaper initially, but the lifetime cost of replacing a large input capacitor would likely outweigh the initial savings. It is also more complex than an AC transformer, so probably not the best choice for this application.

Design

Applications

Powering 3D printer

Workbench power supply

Charging batteries

Requirements

At least 360W output (12V at 30A)

Adjustable DC voltage output up to 24V

120Vac input

Microcontroller

- ~11 I/O pins for 7-segment display

- 2 I/o pins for rotary encoder and power switch

- at least 4 I/O pins for SPI control of digital potentiometer

- 1 ADC for output voltage sensing

- 5V output to power other ICs would be nice

minimum requirements: 17 I/O pins, 1 ADC

Research

Existing Open-Source Projects

Programmable bench power supply EEZ H24005

General

Safety Considerations in Power Supply Design

Common collector amplifiers can be used as voltage buffers

How to Increase the Bandwidth of Digital Potentiometers 10x to 100x

Ripple Port to Reduce Output Capacitor Size

Isolation in Digital Power Supply

Fundamentals of Gate Driver Circuits

Open-source based synthetic medium-voltage grid model for distribution power supply systems

Current Sharing in Parallel Diodes

Microcontroller

Voltage Conversion

This page is a great guide.

Understanding Buck-Boost Power Stages

Similar DC/DC converter with isolation but without adjustable output or display: ~$80

Flyback Transformer

The Active Clamp Flyback Converter: A Design Whose Time Has Come

A Comparison of Different Snubbers for Flyback Converters

Inductor and Flyback Transformer Design

1200 WATT FLYBACK SWITCHING POWER SUPPLY WITH SILICON CARBIDE SEMICONDUCTORS

Inductor volt-second balance, capacitor charge balance, and the small ripple approximation

Flyback transformer design considerations for efficiency and EMI

PASSIVE LOSSLESS SNUBBERS FOR HIGH FREQUENCY PWM CONVERTERS (page 41)

Modules

Flyback Transformer

A flyback transformer would most likely be operated in continuous conduction mode, so transformer size will be limited by core saturation. A toroid with powder core could be a suitable solution.

Switching speeds of MOSFET and diodes should be minimized to reduce switching losses. Winding losses should be minimized as well.

Selecting a Distributed Air-Gap Powder Core for Flyback Transformers

Calculations

With only 30 kHz, a large and expensive inductor would be needed.

Buck-Boost Design Calculations

Digital potentiometer calculations

Conceptual Design

These designs may not be safe or functional. Use at your own risk.

KiCAD Symbol Generator, DB9851.lib, UC24612.lib

Buck-Boost Converter

Flyback Configuration

https://wiki.opensourceecology.org/images/thumb/f/fc/FlybackDraft.jpg/800px-FlybackDraft.jpg

DRAFT, values are not correct

10 gauge wire for secondary winding. Primary has 8.5 turns, try 3 or 3.5 for secondary.

Software

Possible Parts

Output Capacitor: Aluminum (cheaper but more lossy), organic semiconductor (good overall), tantalum (best for surface mount) [1]

Output Inductor: Bobbin or rod-core cause more noise [2]

Isolator: DGTL ISO 2.5KV 2CH GEN PURP 8DIP

Synchronous Rectifier IC: SOT-23-5

Digital Potentiometer: IC DGTL POT 10BIT NV 14-TSSOP

Voltage regulator: IC REG BUCK 12V 1A TO220-5

Buck-Boost Converter

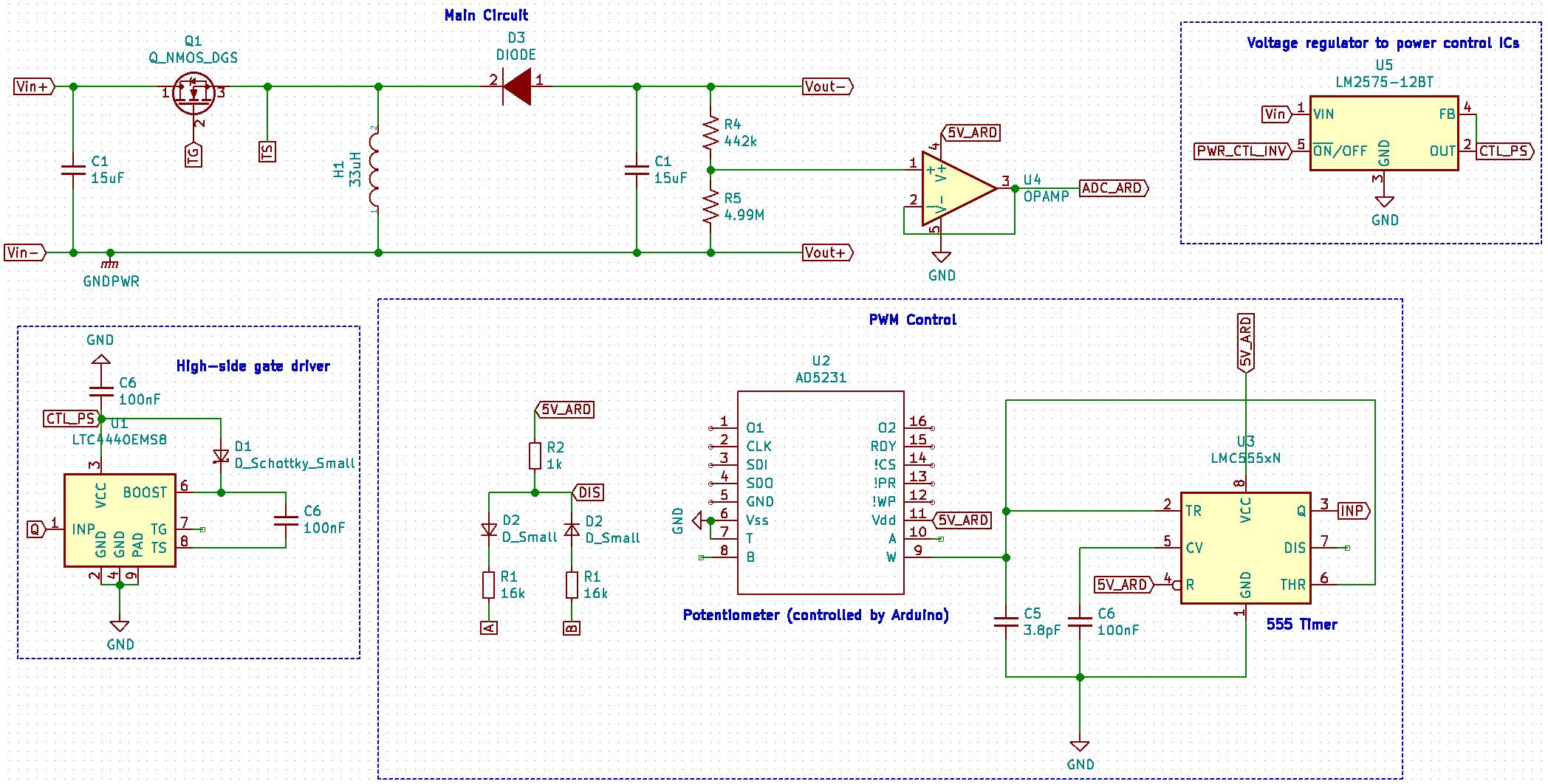

Main Circuit

Switching Transistors: MOSFET N-CH 60V 100A POWERDI5060 or MOSFET N-CH 60V 200A TO-220-3

Inductor: FIXED IND 33UH 30A 1.9MOHM SMD (would require 2.5 MHz switching frequency)

Rectifier Diode: DIODE SCHOTTKY 250V 40A TO220AB

PWM Controller: IC REG CTRLR BUCK/BST 20HTSSOP-B or IC REG CTRLR BUCK-BOOST 20QFN or 555 Timer

555 Timer: IC OSC SINGLE TIMER 3MHZ 8-SOIC

Digital Potentiometer: IC DGTL POT 10BIT 16TQFN and 50 kOhm resistor, or IC DGTL POT 100K SPI 16-TSSOP and 2 x 16kOhm resistor

Input/Output Capacitor: CAP CER 15UF 100V X7S SMD

PWM Control

High-side gate driver: IC HIGH-SIDE DVR HS HV 8-MSOP

Gate driver bootstrap diode: DIODE GEN PURP 100V 200MA SOD80

Oscillation setting: CAP CER 47PF 50V C0G/NP0 0201, 4.7 kOhm resistor

Short circuit protection timer: CAP CER 0.47UF 100V X7R 0805

Error Amp Feedback: CAP CER 0.068UF 100V X7R 0805, 100 Ohm resistor

Voltage Sensing

Voltage divider: RES SMD 442K OHM 1% 1/16W 0402, RES SMD 4.99M OHM 1% 1/16W 0402

Op amp for voltage buffer: IC OPAMP GP 1MHZ RRO SOT23-5

User Interface

Microcontroller: IC MCU 32BIT 64KB FLASH 44LGA ($5, higher resolution ADC) or IC MCU 32BIT 128KB FLASH 64LQFP ($6, similar specs to Arduino Mega)

LCD: LCD 4.5 DIGIT .4" TRANSFL

BJTs: IC PWR RELAY N-CHAN U-DFN3030-10

Forward Configuration

Transformer: XFRMR TOROIDAL 500VA CHAS MOUNT, Investigating ways to salvage transformers

Rectifier: RECT BRIDGE FAST 3PHASE I4-PAC-5

IRFP250NPower transistor (MOSFET) driven by TC1411 1A High-Speed MOSFET Driver with pulse signal originating from arduino.

(Alternative mosfets requiring no mosfer driver) IRF540N "IR" MOSFET N-Channel 33A 100V IRFP250N

Switching Transistor: MOSFET N-CH 40V 95A TO-220AB

Flyback Configuration

Cost of components ~$80

Fuse: FUSE GLASS 15A 250VAC 5X20MM

Bridge Rectifier: 50A, 600V BRIDGE RECTIFIER, GBJ, DIODE BRIDGE FAST DIODE ECO-PAC1, 50A, 1000V BRIDGE RECTIFIER, GBJ

Input Capacitor: CAP ALUM 18000UF 20% 160V SCREW

Snubber

Snubber Diode: DIODE SCHOTTKY 250V 40A TO220AB

Snubber Capacitor: CAP CER 0.18UF 250V X7R 1812

Active Snubber Control: Active clamp flyback controller UCC28780D

Gate Driver Transistors: TRANS NPN 60V 3A TP, TRANS PNP 60V 5A TO-126

Integrated Gate Driver: IC DRIVER HI/LO SIDE 600V 14-DIP

Coupled Inductor

Switching Transistor: MOSFET NCH 650V 21A TO247N, MOSFET NCH 650V 39A TO247N

Transformer: FIXED IND 10UH 16.9A 5.1 MOHM TH, Kool Mu 77130A7 (11.2mm outer diameter, permeability = 125 u)

Output Rectifier

Output Diode: DIODE SCHOTTKY 45V 60A TO247AD

Synchronous Rectifier IC: SYNC RECTIFIER FLYBACK

Synchronous Rectifier Transistor: MOSFET N-CH 40V 95A TO-220AB

Bill of Materials

Buck/Boost Converter Module