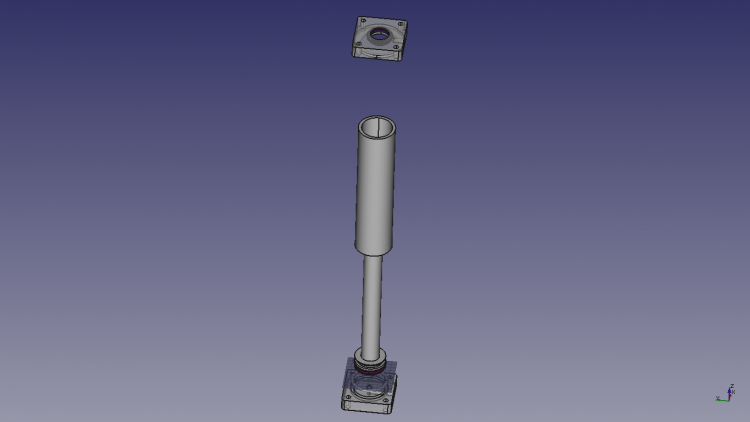

CEB Cylinder

Abstract

The OSE CEB press requires a custom cylinder - 5x8x2.5 inch, but with 3.5" of rod sticking out and no rod end.

The 5" cylinders are about $500 - and an open source version can be half of that if we start from honed cylinder tubing. It is useful to open-source that - as that once more turns every cylinder into a reusable module. The main point of open-sourcing by OSE is standardizing to one build method which allows for universal interchangeability of parts and 3D printed seals, such that any cylinder can be reworked or repurposed easily and inexpensively.

Working Doc

Design by Aidan

Here is a version uploaded to the OSE Wiki. It should work but may have design flaws. I'm using an O-ring to seal the cylinder in the cap trepan groove. This is questionable.

File:Universal Cylinder Builder ADW.FCStd

I've been working on a cad file for the Open Source Cylinder. Here is a link to the alpha stage of the file. DROPBOX The end-caps are square with a trepan machined for the tube to seat. The caps could potentially be parted so that a welding operation replaces a machining operation for the tube seat. The Rod is welded to the Piston in my version.

Like the universal tube builder, I'm trying to make it parameterized from a spreadsheet. Here is what the parameters look like right now:

Name Input (Inches) Output (mm) Note Cap Side Length 4 50.8 Cap Thickness 1 25.4 Tube OD 3 38.1 Tube Wall Thickness 0.25 6.35 Piston Thickness 1 25.4 Piston Seal Inner, Height 0.3125 7.9375 Piston Seal Inner, ID 2.125 26.9875 Piston Seal Inner, OD 2.5 31.75 Piston Seal Outer, Height 0.25 6.35 Piston Seal Outer, ID 2.125 26.9875 Piston Seal Outer, OD 2.5 31.75 Stroke 12 304.8 Rod OD 1.5 19.05 Rod Stickout 2.5 63.5 Cap Seal Outer, Height 0.25 6.35 Cap Seal Outer, OD 2 25.4 Cap Seal Outer, ID 1.495 18.9865 Cap Seal Inner, Height 0.25 6.35 Cap Seal Inner, OD 2 25.4 Cap Seal Inner, ID 1.495 18.9865

Need to add a few parameters like tie-rod diameter. I think the model may need to be scrapped. Especially if one looks at the dependency graph lol. I didn't take as intentional an approach to modeling it as I could have.

I believe it is a worthwhile effort, though. A user could generate the CAD for a cylinder of different sizes by simply entering data into a spreadsheet.

Build Notes

The caps as I have drawn can be easily made on a lathe and mill. I don't know if that is accessible tooling. How i would make this: Cut the plate to size and machine square. Surface grind for extra credit. Put the four tie rod holes in but make them half inch reams. Using shoulder bolts, attach the plate to a lathe jig or 2 bolts and 2 dowel pins. To make the lathe jig, press fit a piece of 4" or similar crs into a thick plate with the bolt pattern on it and weld. Face the jig on the lathe after welding. The bolt pattern should be put in after the welding operation. Use custom vise jaws and maybe a small bore for picking up the center. For the rod end cap, drill and bore the rod hole then bore internal grooves. Then cut trepan groove. For the base, it's just a trepan. Make those in half a day including making the jig.

As an alternative, I was imagining "slicing" the caps into layers, like 3d printing, and then welding the slices together.

For plastic cylinders, I would start with pvc or abs pipe as the tube. I'd go down that road before I started messing with a metal prototype.

I'll keep thinking about it.

Order from East AI Machinery Co, Limited

- 300 kg of honed tubing

- Materials for 5 cylinders

- 3"x4" tubing

- 1-7/8"x3" tubing

- 8 mm rod

Cylinder Parts

- Midstate Hydraulics Part Store

- Prince Part Manual - 5" Bore, Max 2" Rod Diameter

Rods

- Chrome rod - a dollar per kilogram - [1]

- 2" Chrome Plated - Agri Supply

- Stainless rod - 2-1/2 x 22

- 2" SS Rod - Discount Steel

Piston

- 4" Bore 2" Rod Piston

Tubing

- Honed steel tubing - a dollar per kilogram - [2]

- DOM for 5" Bore - rough cut to spec Discount Steel 5-1/2 x 1/4

- DOM for 4" Bore - Discount Steel

Rod Cap

- 4" Bore, 2" Rod Cap - Agri Supply

Press Parts

DOM tubing

- 4" OD x 2.5" ID x 2.5" long - ?source?

- alternate - 3.5 x 2.5 x 2.5 - Discount Steel

- 2.5 OD 1.5 ID 1.5 Long Discount Steel

Sourcing

- Bore 5"

- Stroke 16"

- Rod 2.5"

- Retracted 27" - if we trim it down, cut off 1.5" - and have 1.5" sticking out as is - we need to add 2" to get 3.5" sticking out. But reduce the length by 8" for 8" stroke. We need to trim the cylinder down by 8" - so contracted length to tip of rod is 19". Extended is 27. If we consider extended with 2" of plate - then the distance from bottom of drawer to the pin mount center is 29"

- Extended 43"