CEB Press/Manufacturing Instructions/ElectrohydraulicIntegration

Video

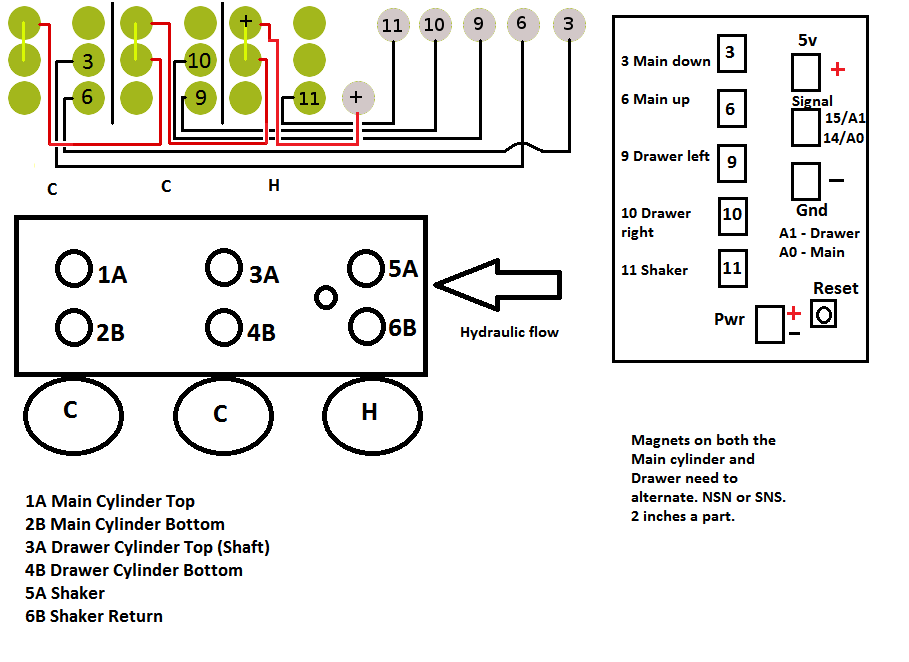

Wiring Diagram

This is an updated drawing that mirrors a successful build as of April 14 2012. It seems the prior drawing was wired backwards and cause the machine to almost run in reverse. What changed was flipping the 3 and 6 wire as well as the 9 and 10 wire. The top of the image shows the solenoid wiring having the shaker solenoid on the right, the drawer in the middle and the main cylinder on the left. When wiring these up you will likely need to move the copper jumper found in the solenoid to the opposite corner. I found that when mounted, the jumper was on the wrong corner and thus moved it to the top left to connect the two terminals there. This is depicted in the drawing as the short light green line. The green dots are the solenoid terminals and the grey dots represent the connections from the control box.

The right image represents the layout of the current Detroit board V2.

The bottom image is the Damon manifold from above and the solenoids attached C,C,H for Main cylinder, Drawer and Shaker motor.

Assembly of the Electrohydraulic Integration

Note that this process should occur only if the solenoid valve set and controller box are already mounted on the CEB press. The process is shown separately from the CEB press for clarity.

Tools

- Screwdriver with Number 2 Philips Bit

- Straight Pattern Tin Snips

- Wire Strippers compatible with 18 gauge

- Crimper

- 10mm Hex Key

- Measuring Tape

Materials

- Controller Box

Ensure that the connections between the top 5 terminals of the terminal platform and the left 5 (MOSFET) terminals of the solenoid driver are such that left to right (terminal platform) corresponds with bottom to top (solenoid driver), respectively. In this case, from left to right the top terminals of the terminal platform are indirectly connected to Arduino pins 11, 10, 9, 6, and 3, respectively.

- Solenoid Valve Set

Ensure that the solenoid valves are mounted to the subplate such that, when the work ports open away from you, from left to right the solenoid valve types are C, C, and H, respectively.

- 18 Gauge Red Wire

- [4] Ring Insulated 14-16 Gauge Connectors

Steps

- Using the tin snips, cut 2 pieces of 30cm red wire.

- Using the wire strippers, strip 1cm at all ends of the 2 pieces of red wire.

- Using the crimpers, crimp the ring connectors at all ends of the 2 pieces of red wire.

- Orient the solenoid valve set such that its work ports open away from you.

- Using the hex key, unscrew the 3 hex caps closer to you.

- Using the screwdriver with the number 2 philips bit, unscrew and remove the lids of the solenoid valve electronics.

- Ensure and relocate if necessary the solenoid valve jumpers such that each solenoid valve has its left-middle and left-top terminals linked.

- Screw the small ring end of the long red 1.5m wire to the left-top terminal of the rightmost solenoid valve.

- Screw the small ring ends of the 30cm red wire to the left-middle terminal of the rightmost solenoid valve and the left-top terminal of the middle solenoid valve.

- Screw the small ring ends of the other 30cm red wire to the left-middle terminal of the middle solenoid valve and the left-top terminal of the leftmost solenoid valve.

- Screw the small ring end of the long black wire of pin 11 to the right-bottom terminal of the rightmost solenoid valve, pin 10 to the right-bottom terminal of the middle solenoid valve, pin 9 to the right-middle terminal of the middle solenoid valve, pin 6 to the right-middle terminal of the leftmost solenoid valve, and pin 3 to the right-bottom terminal of the leftmost solenoid valve.

- Screw on the lids of the solenoid valve electronics.