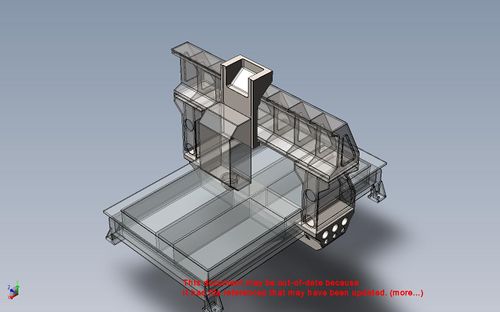

CNC Gantry Mill

Chuck

If it will fit in my mill I can make it. My mills are Servo motor driven and use Ballscrews and Rack and Pinion. I use to build lighter machines but the margins were too low to for the volume I was doing so I started designing and building Heavier machines

To build a 30 HP like the one Blue machine is about $175,000 for a simple barebones machine. They sell for around $350,000 Control package is around $35,000 with motors and drives.

What is the Hydraulic gear pump being used for? I have a 5'x10' Lighter frame sitting here. I planned to use it for a in house machine. But I would sell it at cost to move it out of the way. It is better built then 90% of the Light weight routers but It has been machined and stress relieved and is ready to be assembled. What size machine are you looking to build.?

As far as open source. There is not much in the CNC Router industry that is not open source. They are pretty simple machines. Frame, Ball screws, linear guides, Motors and control.

More

Making pump gears require the part to be milled then Ground to final precision. I have built Gantries that are over 300 feet long and I have build machines used in the medical industry that hold .0001 Before I started building CNC Mills I made parts for the Air craft industry like turbine blades, Landing gear. CNC Milled Putters, Injection mold parts, Five axis heads for CNC mills. Pistons Titanium Connecting rods. Plugs for various molds. For the last 15 years I have been building machines that make parts. I occasionally make parts but mostly I build machines. Engine Blocks are pretty easy to machine. My machines can easily mill the necessary holes and surfaces needed for engine blocks. I did work for TRD boring engines in the late 90's

Most of my machine are designed to hold .0005 which is sufficient for making aircraft parts. Higher precision is achieved by more careful precision when machining the machine, Then ad to that more precise linear guides and ball screws and finally a machine tool control that will compensate for environmental conditions finally any mechanical defects and component wear. I built machines that use laser positioning systems to obtain tolerances needed to make high precision parts. The precision of a machine is proportional to the budget provided to build the machine. What is the application for the Pump?

Offer

I can donate some machine and programming time and surplus material I have laying around. If something requires new material to be purchased I like to cover costs. But I do have ton's of parts I have accumulated over the years that I can donate as needed.

The machines I build use a German control from PowerAutomation I could use an open source control but I have yet to find one that can do what I need it to do. The Blue machine in a 30HP 84 x 140 x 24 Cat 50 Mill. The whight one is a 6x12x4 foot 20 HP that I built to make tire molds. let me know how I can help.

Possible Points of Collaboration

- Open source the controller to save about $30k on the automation side.

- Otherwise, open source technology transfer for the common good, fueling publicity to Chuck