Compressed Air Calculations

Jump to navigation

Jump to search

Reconcile Calculations with Actual Motor Performance

- Compressed Air Energy Storage Calculator - take the case of a single Type K cylinder. Result for energy released from a 200 bar 50l cylinder is 1.5kWhr under isothermal conditions. Baseline energy storage cost is $50/kWhr with a $75 50l 200 bar cylinder, see sourcing at Industrial Gas Cylinders.

- See Compressed Air Motor for 28 cfm/hp figure for mixer air motors.

- If we have 330 cubic feet and we use 28 cfm - we have only 12 minutes of 1 hp from one Type K cylinder. That is not great. If we have one cubic meter internal volume total (20 tanks) - then we have 240 minutes of 1 hp. 4 hp hr at $2000 in cylinder cost - or $500/hphr in storage costs. Compare to $300/kwhr figure for batteries. Batteries are now 2x less expensive. Here we gain 5x over lifetime in cost - if we compare 10 yr vs 100 year life.

- If Energy content of 50l at 200 bar is 1.5kWhr - why am i getting only 90 Whr via a 28 cfm/hp air engine? Air engine is only 6% efficient? Yes.

- Could be - this one is 60% and said to use 10-30% of air. - making standard 6-18% efficient. Could well be. [1]. This tech brief states air engines are 5-20% efficiency, but this one is 60%. I don't believe this standard press release material.

Summary

Air engine efficiency at the small scale is abysmal. It does appear that large scale CAES does get to the 40% or so efficiency, just like normal power plants or gas turbines. At small scale, we get around 10%. Live with it.

- 30 cfm for 0.8 hp (600W) [2]. 35 cfm for 1 kw. 13 cfm for 400W.

- We get 10 min of 1 kW from best motors

- 6 cylinders for 1 kWhr. If the lifetime is unlimited (tank cost) - then we are good. Actually - turbine lifetime will be limiting factor.

- Once again, case for hydrogen or back to superheated water storage. It sounds like a gas-burning engine with air bearings is the only solution - everything else is short life. So there is dev to be done if we are interested in a Zero Marginal Cost Society.

Calculations

- For example, compressed air at 2,900 psi (~197 atm) has an energy density of 0.1 MJ/L calculated from P*deltaV. [3]

- Pressure - N/m2 - 3000 psi = 2E7 Pa. Delta V - of 1 liter or E-3 cu meter - to 214E-3 cu meter.

- PdeltaV=2E7*214E-3=214E4=2E6 = 4MJ for that one expanded liter, as max possible work - but this is just PdeltaV without considering real thermodynamics underneath. Ballpart ok.

- Need to use PV-Work Calculator -https://www.geogebra.org/m/KAZHEN8c

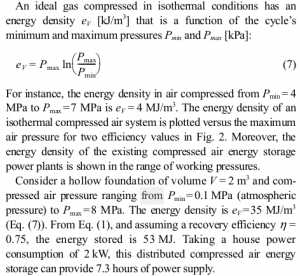

- See formula for energy density - [4]. This shows 50MJ/m3 = 0.05 MJ/l at 50% efficiency

- From [5]

- Type K Gas cylinders are 50l, or 1/20th cu m. Bottom line for compressed air: at about 3000 PSI - energy in a cylinder is 50MJ/m3 at 50% extraction efficiency. Thus, one Type K cylinder has 2.5MJ of energy storage - or 0.7kW hr. WTF????? Right. That is theory, but off-the shelf parts (see Air Motors), even piston ones - are rather pathetic. The Air Motors piston motor gets me 35 minutes of 150W - ar about 75Whr - whereas the calculation of stored energy is 0.7 kWhr above- making the piston engine only 11% efficient. Where are event the 30% efficiencies of air motors coming from? The actual calculation of stored energy based on pressures for a given volume - get us 0.7kWhr. This is a harsh reality - but real for adiabatic expansion. It would be 30% efficient for isothermal expansion - such that we need to tap the isothermal efficiencies somehow. Teh CAES Calculator shows 0.54 kWr - so 0.075 kWhr is a 14% efficient engine based on the calculator.

- Does this check? 20,000*ln(20/0.1)=100,000 kJ/M3 = 100MJ/m3 at 100% efficiency, or 50MJ/m3 with 50%.

- This is rather impressive - 50% efficiency of expansion gets 0.7 kWhr - but heat must be added here to increase the energy output of the expansion engine.

Summary

- Practical (adiabatic) energy extraction appears to be super low, at 10-15%. Isothermal must be a start from the get go- and then it needs to be a magical 70% which by comparing CAES Calculator to isothermal - we get 1.5 kWhr. If we are close to that with highly efficient expansion engines - that would be practical energy. But the adiabatic prediction is simply not matched by reality - the practical air engines completely suck at an apparent <15% mechanical efficiency, excluding the thermodynamic efficiency in the CAES Calculator. So we need to achieve good mechanical efficiency, and good thermodynamic efficiency of isothermal.