Cura Settings

D3D Cura Settings

The industry standard settings for the D3D printer for production printing at OSE are:

- Nozzle size - 1.2 mm

- Layer height - 0.4 mm. This produces really strong, and decent looking prints. You can go down to smaller layers, and go up to 0.8 for really fast prints, but they will not be as strong. 1.2mm/0.4 is the standard setting for very strong and fast prints.

- Print speed - 25 mm/s in cold down to 0C, up to 50 mm/s for easier bulk prints in warm weather, possibly up to 100 mm/s with heated chamber and filament preheat.

- Shell thickness - 1.2 mm; 2.4 for heavy wall

- Bottom and top thickness - 1.2 mm is fine - 2.4 for super heavy

- Infill - 20%

- Filament diameter - 2.85

- Sink object - 5 mm for 3D printed corners

- Brim - typically no brim unless only a small portion of the printed object is touching. Brim lines recommended are typically 5-10

- Raft - never

- Spiralize Outer Contour - for single-line prints

- Line width - even though the nozzle is 1.2 - we can print 1.0 line widths, and even 0.8 mm if necessary for smaller features such as holes near the edge on the extruder.

- Raft - never used in history of the project yet.

More

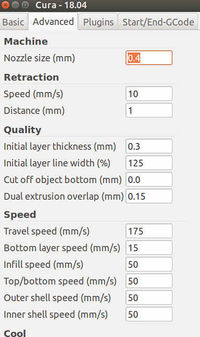

- print_temperature = 230

- print_bed_temperature = 70

- support = None

- platform_adhesion = None

- filament_flow = 100.0

- retraction_speed = 40.0

- retraction_amount = 2.5

- bottom_thickness = 0.3

- travel_speed = 50

- bottom_layer_speed = 25

- infill_speed = 25

- solidarea_speed = 25

- inset0_speed = 25

- insetx_speed = 25

- cool_min_layer_time = 10 - this will slow the print down if a layer takes less than 10 seconds to print

- fan_enabled = True

- skirt_line_count = 3 - this is activated if brim is disabled. Allows flow to start prior to actual print

- skirt_gap = 3.0

- skirt_minimal_length = 150.0

- fan_full_height = 1.0 - print cooling fan activates after 1 mm of height

- fan_speed = 100

- fan_speed_max = 100

- solid_top = True

- solid_bottom = True

- fill_overlap = 15

[alterations] start.gcode =

M92 E100 ; sets extruder steps per mm for Universal Gearless Extruder

M203 Z10 ; override max Z feedrate from 5 to 10 mm/s so that z homing is faster

G28 X0 Y0 ; home

;G0 X40 ; Move over offset for X. D3D Universal does not use this offset. It is used in Pro. This is to place the probe over the bed upon startup

;G0 Y40 ; move over offset for Y. his is to place the probe over the bed upon startup

G28 Z0 ; z homing G29 ; autolevel G90 ; set absolute coordinates (should already be absolute by default - probably get rid of this)

G92 E0 ; reset the extruder origin - whithout this, there were interesting artefacts ;M851 Z-2 ; Set the Z probe offset to -2. Used only for first calibrations.

end.gcode = G28 X0 Y0 ;move X/Y to min endstops, so the head is out of the way

M104 S0 ; make sure the extuder is turned off.

M140 S0 ; make sure the bed is turned off.

;G0 Z320 ; take bed back down. Not used in D3D Universal, used in Pro

M84 ; steppers off. Probably better to keep this on in Universal, so head doesn't drop onto the print at the end

Object Design Notes

- When designing objects with large flat bottoms, put a chamfer on the bottom so that you can get a tool under the chamfer to pry the object off the print bed.

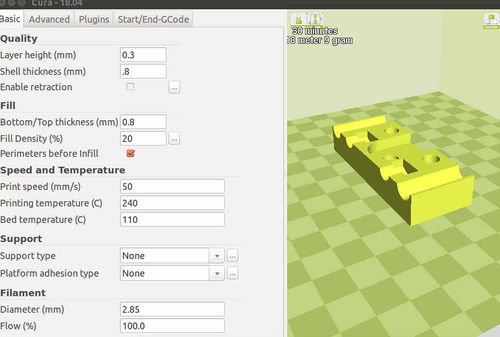

.4 mm Nozzle on Lulzbot Mini

This is what I did for 0.4 mm nozzle, as opposed to 0.5 standard. I reduced the values until the yellow highlight disappeared, assuming that the yellow highlight is no go. Result was stringy, so I left the settings at the 0.5 settings when using the 0.4 nozzle, and it worked much better.