D3D v20.04 Build Instructions

Jump to navigation

Jump to search

Build Procedure

Almost completely there:

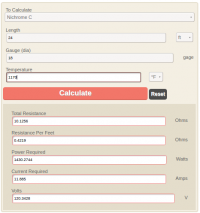

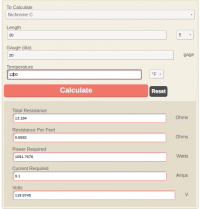

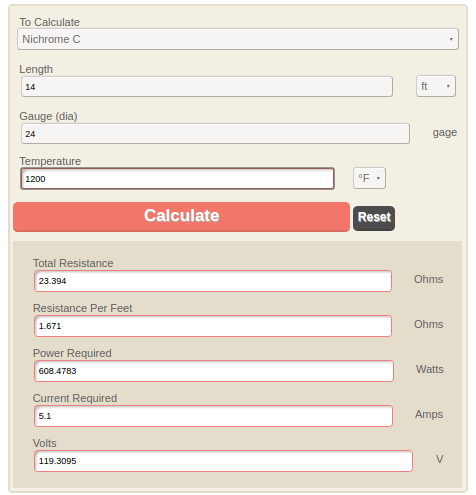

Heater Element for Bed - 24 Gauge

(See Nichrome Calculator)

Includes 2 strads of heater element - each 600W strong.

Notes:

- Length of 24 gauge nichrome - 14 feet

- Fiberglass sleeve used - HTG fiberglass, does not fray like standard high temperature sleeving (1000F) and is rated for . See [1]. Note that the resin can burn out at the 650C (1200F) workign temp. Sleeve has VW-1 flame resistance. Made of fiberglass, it does not burn out, but may fuse and lose fiber structure.

- Inner core: 5' long wraparound of 2mm tight braid fiberglass sleeve - 600C - [2]. Started with 5', wrap was more like 4' long.

- This is packed into 4' of 6 mm tight braid fiberglass sleeve.

- Fence wire is used to couple 200C wire to nichrome, in order not to burn out 200C wire. Nichrome is wrapped around the fence wire 5-10 turns

- Copper wire is soldered to the fence wire.

- 10" end piece of 6 mm tight braid sleeve covers the 200C wire, fence wire, and ends of nichrome.

- 2 strands of 24 ga nichrome heater element are made, each 14' long, each about 600W.

- Ends, covered by 6 mm tight braid sleeve - stick out the finished bed. Third wire set is the thermistor, which is wrapped with 2 mm tight braid so it doesn't melt out.

Heater Optimization

Theoretical idea:

But, ga 18 can't bend easily using a cordless drill.

- 20 feet of 20 ga wire appears to be most convenient - 1 piece, max at 1200F. Current 500W heater is 1200F max, and works well.

- Winner: 14 feet of 24 ga works perfectly by hand to get a good wrap over 4 feet, and goes fast, about 1 minute pending tieups: