Design for Fabrication

Introduction

Design for Fabrication is design which considers ease of fabrication as the primary goal. This does not mean that performance is compromised regarding the intended purpose of the machine. Moreover, design for fabrication should consider not point performance, but Integrated Performance - performance which considers a large number of factors.

Example

See an example of the engine mounting plate for the Power Cube.

The point is, the mounting plate is a 1/4" plate with some holes. Nothing else. Simple to fabricate with the minimum parts.

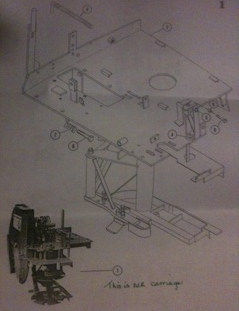

Compare this to this engine mount plate on another device, which is not so simple:

Note: that may be a bad example, since we are considering different functions (the latter is an engine mount plate from the Mobile Dimensions sawmill), but the fact remains that the latter could be simplified if design-for-fabrication were an objective. This simplification has indeed been shown in OSE's Dimensional Sawmill.

14 principles of design for DIY production

In contrast with the industrial organisation of production, DIY production settings imply a voluntary limitation in access to means of production, including manpower, tools, skills and investment capacity. These limitations imply in turn limitations in terms of achievable product size, complexity and accuracy.

In order to be suitable for DIY production, products designs have to integrate those limitations. Here are 14 design principles that can help:

- Use modular design. Modularity, i.e. the distribution of sub-functions of the product among distinct functional carriers with clearly defined interfaces, can help achieving a clear separation of vitamins[1] and DIY parts. Example: De-couple energy source and usage, so that any type of source can be used (e.g. electric motor, hydraulic pressure) for generating a given movement.

- Opt for processes that can be performed with standard tools. The more widely available the required tools are, the more probable it is that it will be accessible to anyone. Example: bolting instead of welding.

- Use commonplace materials. The more widely available the required materials are, the more probable it is that they can be purchased by anyone. Example: wood plate in sizes available in hardware stores.

- Use discarded materials and materials that are to-hand. Designing a product made of discarded materials that can be commonly used in households may be a solution for facilitating purchase. It should be however considered that discarded materials may have lower accuracy and require pre-processing steps. Example: contactless bicycle dynamo made of hard disk drive magnets.

- Use general purpose and standard components. Standard components may be more easily available than exotic ones. Using them may therefore ease the purchasing process. Example: widely available standards nuts and bolts that can be found in hardware stores.

- Facilitate for tailoring. A motivation for making a product in a DIY setting is to get a tailored product. Flexibility can be built in the product design in order to ease the tailoring process. Example: parameterized bicycle frame design.

- Facilitate for flexible construction. Giving a scope for last-minute tweaking in case the design cannot exactly be realized as described in the product requirements would allow overcoming shortages in the production process. Example: high geometric and material tolerances, beams with a grid of equally separated attachment holes.

- Prefer reversible to permanent joining features. Using removable and adjustable joining features allows accommodating mistakes or correcting misalignments in the assembly. Examples: interlocking elements, nuts and bolts vs. welding.

- Reduce vitamin variation. When several vitamins are required, using the same vitamin each time could help reducing the purchase and storage effort. Examples: one type of bolt for the assembly of all parts of the product, one type of step motors for translating the plateau of a machine-tool in all three directions or space.

- Reduce raw material variation. Strive designing all DIY-components so they can be made out of the same material and using same processes. This would allow reducing the purchasing effort and the requirements for processing tools. Example: 3D design made of assembled laser-cut plywood.

- Use symmetries. Using symmetries is another way of reducing part variation, to use several times the same part and to profit from learning curve in the production. Example: the frame of a 3D printer that is symmetrical along the slider rail of the printing head (left-right axis) can be assembled using same joining features for both left and right sides.

- Offer scalability through “stackability”. Building a product of a large size/power may be more difficult than building numbers of small products that can be combined in order to reach the desired size/power. It reduces the risk and need of handling larger and heavy products. Example: A high luminous emittance can be reached by combining several LED.

- Ensure ease of handling and transportation. Bulky or fragile products may be difficult to handle and require specific handling or holding mechanisms. In those case, use built-in handling mechanisms or provide DIY handling tools. Example: wheels and contact points built in the frame of the product, DIY building jig.

- Offer different depths of DIY. Not everybody have the same skills, tools, and interest in building things. It may be interesting giving the maker the possibility to choose by itself, which of the parts he or she considers as a vitamin. Example: a product with parts that can be either 3D-printed or bought as a kit.

The content of this section is a reworked excerpt of the following publication: Bonvoisin, J., J. K. Galla, S. Prendeville. 2017. Design Principles for Do-It-Yourself Production. Accepted for publication and presentation at the 4th International Conference on Sustainable Design and Manufacturing, Bologna, Italia, 26-28 April. (to be published).