Dwiel House

Summary

The Dwiel House is a house designed to be built with CEB Bricks, and other natural, sustainable, local, non-toxic, easily diy fabricated materials. The first instance of this house is being built in Bloomington Indiana at Dandelion Village. I am filling in details about the construction here, and there is also a blog.

Design Rational

- Low cost

- Mostly local, sustainable, non-toxic materials

- locally milled lumber

- soil for CEBs from onsite

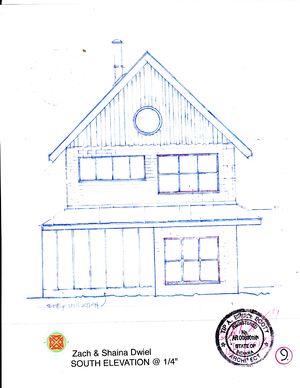

- Passively heated - the house has been designed to not need a heating system except for the coldest few weeks of winter

- Easy to build

- Winter greenhouse

Materials

The following materials are used:

- Earth - walls, floors

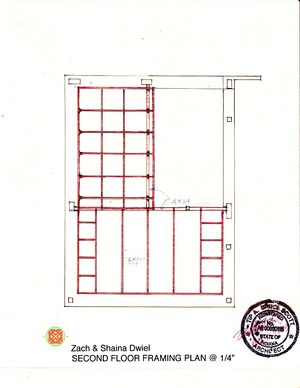

- Wood - 2nd floor, ceiling joists, floor joists, roof rafters, shelves, stairs, framing, window/door bucks

- Metal roof, screws and bolts

- Gravel - foundation

- Concrete - foundation

- Pine tar - water proofing

- Rice hulls - insulation (walls and roof)

- Glass - windows

- Perlite - insulation (floor)

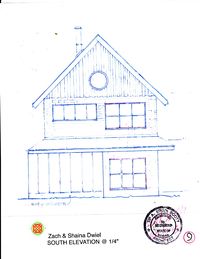

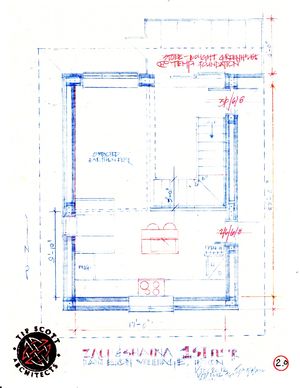

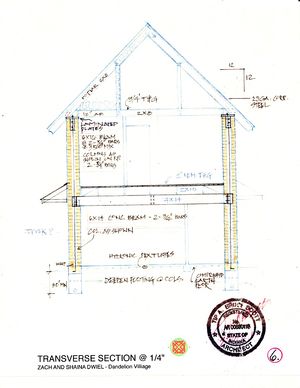

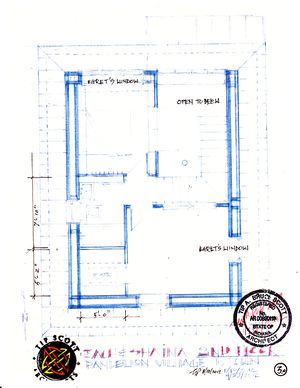

Architectural Drawings

Foundation

Diagram

Water

The foundation we are using is a typical rubble trench foundation. We are using pine tar as a water sealant, though we may also add a layer of metal flashing between the foundation and the materials sitting on top of it. We are using rice hulls for insulation in the walls, but are using perlite for the first few inches so that in the event that some water condenses in the walls and collects at the bottom of the wall cavity, minimal rotting will occur.

Heat

A 6x6 block of wood is being placed around the inside perimeter of the walls to act as a thermal barrier between the concrete and inside CEB wall, both of which have no insulating properties. Without that block of wood, heat would travel from outside through the foundation and up into the inside CEB wall as if the wall was a large radiator resulting in significant heat loss. A similar approach is taken in the floor. Perlite will go up to the edge of the foundation and a thinner CEB block around the very perimeter. This is so that all heat will have to travel through either the CEB and perlite or some CEB and wood before reaching the cold foundation. Some people partially avoid this problem by insulating the outside of their foundation with pink foam board, but we decided that we would rather use this approach as the wood can be sourced locally and is non-toxic compared to the foam board which is made in a distant factory with lots of chemicals. The perlite, though not produced in a nearby county is mined and distributed in Indiana and Ohio which are nearby to us and have simple supply chains. This is the same stuff that is commonly used to fill in the holes left when building concrete block walls.

Insulation

We are using 12" of rice hulls in the wall cavity, 18" of rice hulls in the roof and 6" of perlite under the floors. See also Foundation-Heat and Heat Loss Analysis

Heat Loss Analysis

There is a detailed heat loss analysis here. We expect to have about 15 square meters of south facing glass which will bring in about 66 kBTU/day on a sunny winter day. We expect to loose about 93 kBTU/day when inside temperatures are 63 and average outside temperatures are 20 degrees. This is the worst average Indiana day. We can also store a significant amount of heat in the thermal mass of the floor and walls. This means that even if we loose 20 kBTU/day the temperature will drop by less than 0.2 degrees/day. This thermal mass also means that when we do need external heat, we can burn one fire and have the heat last a few days or a week.

Costs

There is a detailed costs spreadsheet below. One thing to note is that costs like CEB Press and other tools are included in the total. This makes the cost much less than the total as the second house will cost significantly less. OSE typically refers to costs by only their per unit cost and doesn't include the cost of tools in estimates.