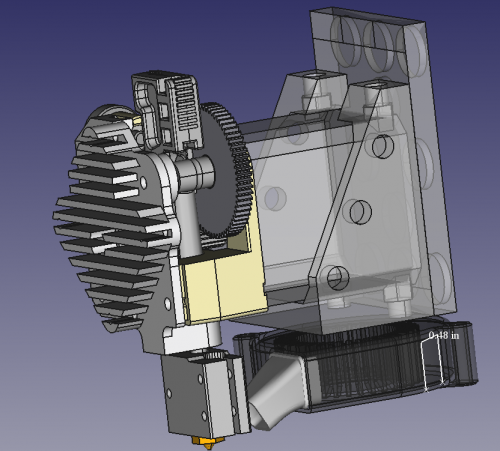

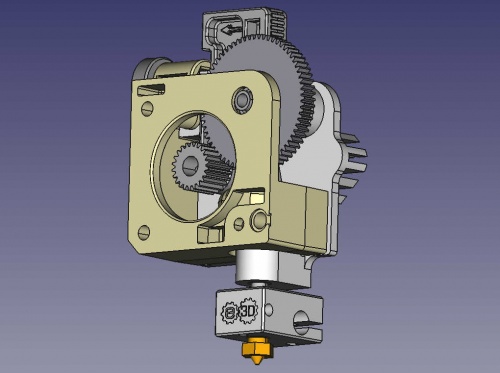

E3D Titan Aero Extruder

Upgrade and Simplification Sep 2018

It turns out that the extruder motor mounts directly to carriage piece via rear screws on the motor using M3x30 screws with washers. Clam of carriage used 3 of the diagonam M6 bolts for closure, and 2 of the opposite diagonal bolts for attaching the extruder to the carriage.

CAD Generation

- Start with FreeCAD Lesson - Designing a Sensor holder for the Titan Aero

- To this, add a fan mount for a print cooling fan - File:Fanwithholderpattern.fcstd

Build June 2018

MJ built this and it suffered from interference that stalls the blower fan. Fan must not be too close to the stepper motor.

Download in FreeCAD format - [1]

Introduction

An open source extruder for regular and flexible filaments that can also be used with the Volcano heater block + nozzle for printing with volcano 0.6 mm to 1.2 mm nozzles.

Build Instructions

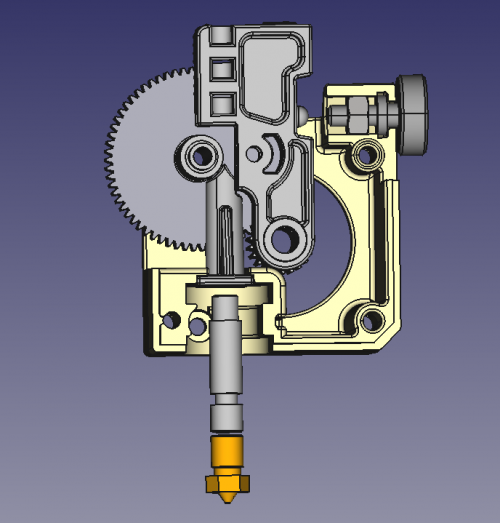

Bugs

- Grub screw on pinion gear interferes with the second gear because the grub screw is not recessed. This requires more precise mounting of the pinion gear, and disallows usage of the extruder without a mount plate. A 2 mm spacer is needed for use with the standard D3D Extruder Holder.

Titan Extruder (not aero)

- https://e3d-online.com/titan-extruder - Is there any advantage of Aero to the Titan?

Titan Aqua

- Liquid Cooled for warm and heated chambers - [2]

Moarstruder

- 100 g/hr flow rate - [3]

Shopping

- Authentic - Matterhackers - 12V, 3mm - regular (not mirrored)- [4]

- Authentic volcano heater block - - [5]

- Titan Aero 3mm - $120 on Ebay - [6]

- Aliexpress - $67 - [7]

- Volcano Hot End + Nozzle - [8]

CAD

- Aleph Objects has produced a FreeCAD version of the Titan Aero extruder - [9]. See Mirrored_aero_assem.fcstd file

Note that Titan Aero 3 mm extruder has 6 mm thread on both sides of heat break, while E3D v6 1.75 has 7 mm on cold side (for teflon) and 6 mm on the nozzle side. This is from the Lulzbot file:

Part Library

- Overall library - [10]

- 8 mm sensor - [11]

- 8 mm sensor holder - [12]

- Heater block only - [13]

- Unmirrored Titan Aero extruder - [14]

Data Collection

- 5/16/20 - 2 of 6 Titan Aeros in printer cluster got stuck for no reason. Took it apart. No visible stuckage. After putting it back together, the filament went right through. Fault happened in both cases as brittle filament broke. In one case, pathway was free from any blockage. Filament just did not feed until extruder was disassembled. Suspected cause: misalignment between neck and heat sink.

Links

- Titan Aero Assembly Instructions

- Jamming issues - [15]. This appears to be with 1.75 mm. OSE recommends 3 mm for more push.

- Discussion of some ridiculous issues with Titan Aero clones - [16]

- Trianglelab clone appears sound, with hardened steel drive gear - [17]. They appear to have included the hardened steel instead of plastic based on feedback.