Elliot's Pyrolysis Reactor Prototype

Concept

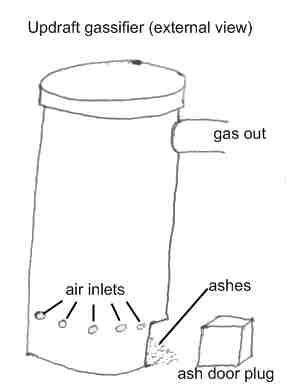

I propose an updraft gasifier for the combustion stage. This mode of gasification is the simplest, and is often not used because of the excessive non-volatiles it produces (a downdraft gasifer is equally simple and tends to reoxidize heavy oils into gases). Long-chain hydrocarbons are partially oxidized to yield combustible gasses, oils and tars.

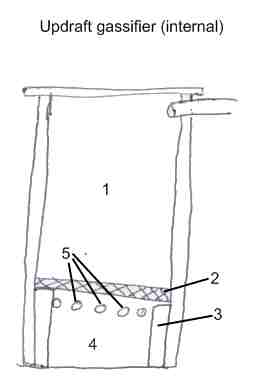

This reactor is intended to be ceramic, both lid and main body. Use of castable refractories allows one to use local materials (local clay and sand) for much of the construction, makes for easily scalable reactors (as opposed to trying to source a larger metal container) and is dirt cheap. The metal required is for the ash screen and for the gas outlet pipe (which will need to conduct heat well for quenching).

Improvements

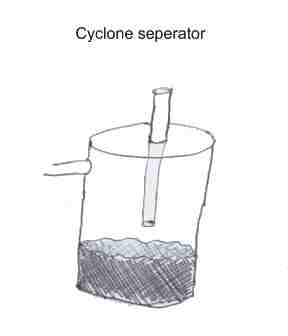

The pipe leading to the cyclone separator and the body of the separator itself should be cooled in order to quench the gas stream and minimize post-pyrolysis reactions (recombination to form larger molecules). I expect that cooled pyrolysis gas, forced back into the gas stream before the separator, will help quenching significantly, and free radical combination of the pyrolized stream with the cooled gas stream may produce more light-weight oils, as reactive molecules are more likely to combine with unwanted gasses rather than with other heavy molecules to form tars. Pyrolysis gas forced back into the reactor along with the air also would increase the likelihood of gases being converted into oils.

not included so far

I have not proposed yet a method for quenching the gas stream. Perhaps if the gas outlet pipe ran through a larger diameter pipe with water flowing into it, and the separator barrel was inside a larger barrel full of water, that would be enough. also, cooled pyrolysis gas or oil pumped into the separator would work better than contact cooling.

Also, gas recirculation into the air inlet would be an improvement for the future.

And, there will be some ash in the oil. The gas stream filtering through the biomass may minimize that (updraft). Perhaps another metal screen above the biomass will help.

Drawing

1. Biomass chamber 2. ash screen 3. firebrick to support screen 4. ash chamber 5. air inlet holes

Parts List

gasifier:

clay

sand

cardboard (for casting forms)

.5m x .5m metal screen

small diameter stove pipe fitting (cast into body)

small diameter stove pipe

Separator:

5 gal metal container

stove pipe (for inlet and outlet)

quenching:

larger diameter stove pipe

sheet metal (ends of concentric stove pipe heat exchange)

large barrel

hoses, water source, use for hot water, etc.