Fabrication Diagram

Overview

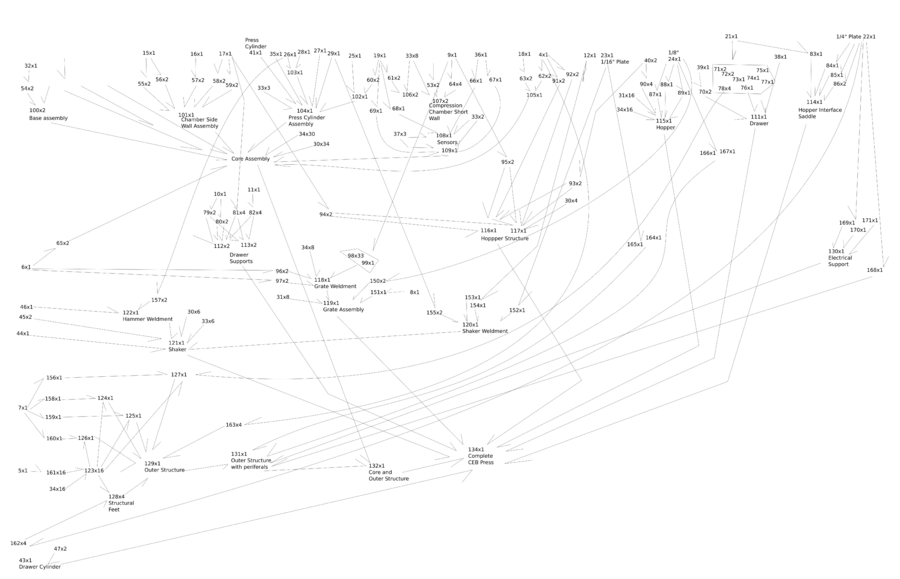

The Fabrication Diagram is a diagram that facilitates the build of a prototype. It contains a visual representation of all fabrication steps and parts. The visual representation allows the fabrication team to understand which steps may be taken in parallel and which steps are done sequentially. Each step links to a fabrication drawing. Supporting files are arranged in well-organized folders.

Example

Summary: (click thumbnail below) a fabrication diagram shows how all the components (identified as numbers corresponding to fabrication drawings) of a machine go together, and in what order they are put together - focusing on the order of fabrication by parallel team (8 or more people or pairs). This allows one to allocate people to tasks. The fabrication diagram shows what tasks may be parallelled.

Sample fabrication diagram from October, 2012 build of the brick press.

Challenges

One needs to look up the part numbers in a book/PDF of drawings. It may be useful to follow Module-Based Design here more closely - starting a Fabrication Diagram with general module sequence.

The best application of this method can happen when CNC cutting is used - such that most parts are cut automatically and are ready prior to a build - and assembly can happen with a significant number of people.

Fabrication Diagram Process Overview

click edit to access links or edit. There are embedded links

Fabrication Tree Diagram - Process Standards

- Diagram shows every fabrication step of procedure as a unique numbered or named item

- For example, a stock piece of metal, from which a piece of metal is cut to size - is shown as an item in the diagram

- Every item in diagram is either numbered or named so it can be placed in the fabrication Tree Diagram Index

- Every item in diagram corresponds to a Fabrication Drawing

- For simple parts, several parts can be placed on a single Fabrication Drawing - but each part must be labeled so that it can be indexed in Fabrication Tree Diagram Master Index

- Master Index lists all components as unique entries - from primitive stock to fabricated assemblies

Sample Fabrication Drawing Set

This is an example from the CEB Press. Each drawing number corresponds to a part in a Fabrication Diagram and to a part in the Master Index.

More

By visually placing fabrication steps horizontally on a page, we know that several steps can be taken in parallel. Items going down the page, or vertically down - are subsequent steps that have dependencies on prior parts being fabricated. This technique is useful when a team of fabricators is involved in production, such that fabrication can be done in parallel. We are testing this method to build a CEB Press in one day with 8 people.

See blog post where Fabrication Diagram is first introduced.

Description

At minute 6:40, cold saw example. Use part reference number independent of what part is (specifications of part)

- Diagram

- Index

- Component folders

Download the Cold Saw Example - see the Index and Components - [1]. The difficulty here is access to Solidworks, so we are considering switching to Sketchup. While less powerful, Sketchup allows for wider collaboration because everyone has access to the software.

Here's a preview: