Fanuc Industrial Robot

Entertainment

EMC2 IRC Chat

Right on, so it should be no problem. Where do I see the documentation on that kinematics software part?

<andypugh> http://www.youtube.com/watch?v=80YhX73DuSg is an industrial robot running the completely standard EMC2 splash-screen code:

<andypugh> The docs are a little sparse. <andypugh> http://linuxcnc.org/docs/html/man/man9/kins.9.html

Ok. Are there any people in the group who use EMC2 to run robotic arms? I can get my hands on a Fanuc, without the controls from a guy Joshua who I think has been also on this IRC.

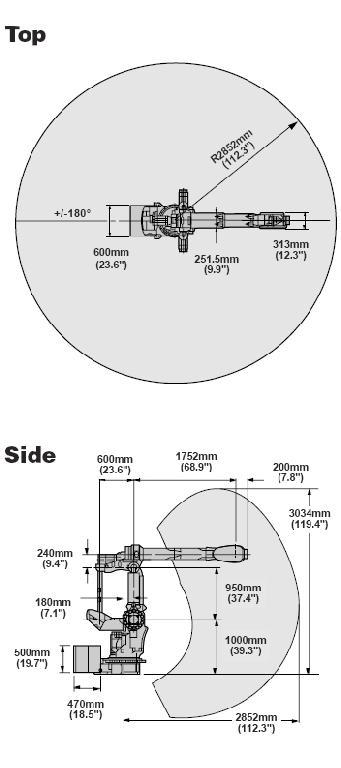

<andypugh> Yes, Stuart has a robot <marcin_ose> So 6 axis is no problem? <andypugh> Or do you mean on this actual IRC chat? <andypugh> Genserkins can handle up to 6 joints. (and it is a simple compile-time switch to add more) <marcin_ose> Awesome. I can get this: http://openfarmtech.org/wiki/Fanuc_Industrial_Robot <marcin_ose> How do I generate the toolpath file, is there any open software available for that? <andypugh> Ooh! Fanuc red-cap motors! I have been wanting to see if my bldc component can really handle them. <marcin_ose> What's BLDC? <marcin_ose> Andypugh, where are you located? <marcin_ose> Maybe you can come for a visit and help me, i'm in the Kansas City area. <andypugh> With EMC2 your robot arm uses normal cartesian G-code, and the kinematics software converts that into joint positions. It's all done by magic. <andypugh> I am in the UK, (and that is not Upper Kansas) <marcin_ose> Ah. <marcin_ose> Ok, is the kinematics software open source? <marcin_ose> Do you have a link? <andypugh> It's part of EMC2

EMC2 With Robotic Arms

<marcin_ose> Right on, so it should be no problem. Where do I see the documentation on that kinematics software part? <andypugh> http://www.youtube.com/watch?v=80YhX73DuSg is an industrial robot running the completely standard EMC2 splash-screen code <andypugh> The docs are a little sparse. <andypugh> http://linuxcnc.org/docs/html/man/man9/kins.9.html * rooks has quit (Quit: So long, and thanks for all the fish.) <andypugh> Basically, where your HAL file says "loadrt trivkins" you make it say "loadrt genserkins" and then you need a bunch of lines like setp genserkins.A-0 20 to set up the robot geometry. <andypugh> and back to a previous question, bldc means Brushless DC Motor, which those Fanuc red-caps are. <andypugh> If you have the Drives then it is easy but making them work with generic drives is a lot more fun. I am confident that I could do it with the modules that EMC2 has for that purpose. <marcin_ose> Is the problem statement that of sourcing a generic drive for a BLDC motor, if we don't have the original drivers? <marcin_ose> I would want to go straight to a generic drive. <marcin_ose> So when it breaks, I know how to fix it. That's a necessary first step for me. <andypugh> Fanuc motors use a unique 4-wire feedback to tell the drive what the motor rotor position is, so that it can power the correct windings to make torque. <andypugh> Most motors use 3 wires, and most drives need 3 wires. <andypugh> The Mesa 8i20 ought to run them, in combination with the bldc component. <andypugh> There is a half-written Wiki page on the subject here: http://wiki.linuxcnc.org/emcinfo.pl?BLDC <marcin_ose> Aha. <marcin_ose> Did you write the BLDC info page? <marcin_ose> How much do the Mesa drivers cost? <andypugh> Yes. I wrote the 8i20 driver and the bldc component too, for just this kind of problem. <andypugh> The drives are about $250 each, and the controller card is about the same (one controller can run 32 drives) <marcin_ose> Ok. The mesas are on the scale of hundreds of dollars in cost? * JustinXJS3 has quit (Quit: Leaving) <andypugh> Yes. That is cheap for a brushless motor drive. They are 2,2kW, 400V, 20A drives. <andypugh> You might find some drives on eBay, and EMC2 _should_ be able to convert the 4-wire Fanuc feedback into 3-wire Hall feedback. It is untested, but if it doesn't work it needs to be fixed. <marcin_ose> Is it desirable to design a through-hole circuit-millable version of that drive? <marcin_ose> I'm just trying to wrap my head around the problem statement for low-cost robotic arms. <andypugh> The problem is that you need a lot of force. <andypugh> which tends to mean big motors. You also need very low backlash, which means that you can't do it with gearing. They tend to use harmonic drives, and those are expensive too. <marcin_ose> Aha. Can we mill harmonic gears on a basic CNC mill with indexing head? <andypugh> I can't see it being easy. <andypugh> I wonder if a servo-hydraulic robot might work? Imagine a CNC JCB digger. <andypugh> You would need joint feedback, and electrically controllable hydraulic valves. <marcin_ose> That's my thought! We're good on hydraulics. I don't see why a servo-hydraulic can't work. We'd have to use a low-backlash hydraulic motor, though. <andypugh> Why not just conventional hydraulic cylinders? <marcin_ose> Cylinders would have limited motion capacity? <marcin_ose> It seems rotary is more versatile. <andypugh> We use them at work for simulating road load driving. They drive a car over a course with instrumented wheels, then they play-back the forces with an <andypugh> elaborate 6-axis system of servo-hydraulic cylinders for weeks and weeks non-stop. The speed and force that the cylinder achieve is astonishing. <andypugh> But yes, rotary will give more movement (unless you go for secondary arms, or rack-and-pinion actuators. <marcin_ose> Andy, can you be our advisor for the robotic arm? http://opensourceecology.org/gvcs.php . Your job would be a technical discussion, 1 hour every 2 weeks. Do you have the time? <marcin_ose> That is a good addition to an open source microfactory. <andypugh> I really know very little about robot arms, there are people who know far more than me. <andypugh> (including the voices you can hear in that Youtube video) <marcin_ose> Are they on #emc ? <andypugh> I think one of them was cradek <andypugh> The robot arm itself is in Wichita.

EMC Users with Robotic Arms

There is a Board of Directors: http://www.linuxcnc.org/content/view/12/10/lang,english/

<atom1> andypugh, who's arm is that? <andypugh> Possibly SWP. <andypugh> I don't know, I wasn't there. <atom1> but you say it's in wichita? <andypugh> Yes, the Fest was held in the workshop at http://www.mpm1.com/ <atom1> about a mile from me <atom1> :D <atom1> or less <andypugh> The Cincinatti is probably the biggest machine that is controlled by EMC2 at the moment <atom1> who's shop is that? <atom1> someone here? <mozmck1> stuat stevenson <andypugh> I don't know if he is on the IRC, but he is on the mailing list. <mozmck1> he gets on here occasionally I think. <mozmck1> Stuart that is...

marcin_ose: there have been several EMC2 get togethers in Wichita KS, they call 'em fests.

Andy/Marcin,

The FANUC S420iF, it's sister machine and two RJ2 controllers are mine. I also have the pendants and 3-4 book on them. I initiated the most recent EMC2 conversation regarding these machines in an effort to honestly convey them to the OS Ecology community in MO. My previous research and information gathered from the EMC2 group leads me to believe that they could be quite easily retrofitted to EMC2 control by someone with the right skillset. This person is not me... I will upload more photos early next week when I get a chance to go look at them. I would gladly retrofit the arms for use as a router, trimming unit, adhesive applicator or whatever else was required.

JOSH 04/24/2011