Hydroponic system design considerations

There are several design considerations and trade-offs to take into account when designing a hydroponic system:

- Yield (maximize output and minimize time between harvests)

- Use of space

- Materials

- Parts

- Power consumption

- Water consumption

- Nutrient requirements

- Usability (simplify installation, use and maintenance)

- Risk mitigation (see corresponding chapter below)

Yield factors

In conventional agriculture, yield is the mass of harvested agricultural output per unit of land area, typically kilograms per hectare. In hydroponics units of volume can be used instead of units of area, since vertical stacking is an option, e.g. kilos of cucumber per cubic meter (kg/m3). Time is also a relevant factor for measuring the output of a hydroponic system, e.g. kilos of cucumber per cubic meter per year (kg/m3/year.)

Crop yield can be maximized through the following factors:

- Growing technique

- Light (intensity and time cycles)

- Air temperature

- Temperature in nutrient solution

- Nutrient mix

- pH (acidity in nutrient solution)

- EC (Electrical conductivity in nutrient solution

- Water flow (not applicable for all growing techniques)

- Droplet size of nutrient solution (applicable for aeroponics and fogponics)

- Humidity

- Aeration of nutrient solution

- Airflow in grow environment

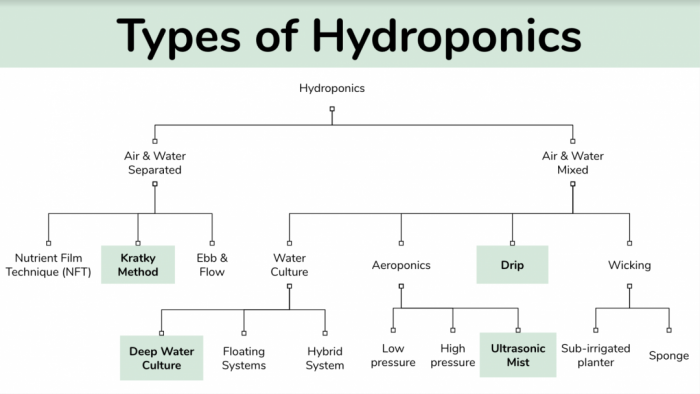

Growing techniques

Hydroponics can be combined with aquaculture where aquatic animals such as fish, crayfish, snails or prawns are raised in tanks. This is known as Aquaponics

Aeroponics and fogponics

There are three types of aeroponics:

- Low pressure aeroponics (LPA)

- High pressure aeroponics (HPA)

- Ultrasonic mist hydroponics

High pressure aeroponics and Ultrasonic mister hydroponics are also known as Fogponics.

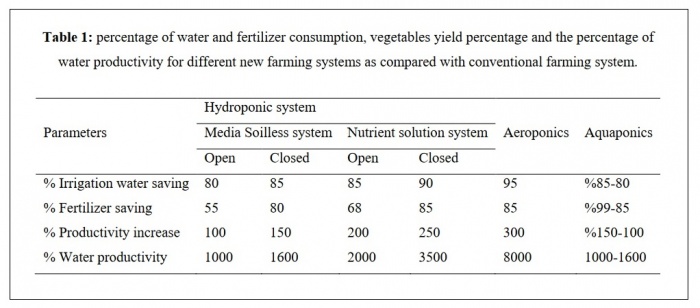

Efficiency of aeroponics and fogponics

Compared to soil-based cultivation, aeroponics uses 99% less water, 50% less nutrients and 45% less time between harvests.[1]

Compared to soil-based cultivation and other hydroponic systems, areoponics can produce a 45%-75% higher plant yield.[2]

The table below compares water saving, fertilization saving and productivity of different cultivation systems.[3] [4]

Droplet size in aeroponics and fogponics

Droplet size is a factor in aeroponic and fogponic systems.

Ideal droplet size range for most of the plant species is in-between 30 and 100 microns.[5]

Within this range the smaller droplets saturate the air, maintaining humidity levels within the growth chamber.

Droplets below 30 microns tend to remain in the air like a fog and fail to achieve continuous plant growth. Droplets over 100 microns tend to fall out of the air before containing on the plant root, and too large droplet means less oxygen is present in the growth chamber.

Use of space

Ideally, you want to grow as many plants as possible per unit of volume. Different systems, i.e. combinations of Hydroponics methods and System Designs, allows for different number of plants per cubic meter. The possibility of vertical stacking with hydroponics adds a dimension of flexibility and more output per area.

| Plants / m3 | Method | Design | Calculation (plants / m3) | Example product link |

|---|---|---|---|---|

| 49.6 | NFT | Rack | n/V = 96/(1.3*0.85*1.75) = 96/1.934=49.6 | https://cityfarm.my/products/city-vertical-farm-xl-indoor-nft-system |

| 104.8 | NFT | Tower | n/V = 80/(0.67*0.67*1.7) = 80/0.763 = 104.8 | https://www.alibaba.com/product-detail/Tower-Hydroponic-Grow-Systems-Complete-Vertical_1600065843280.html?spm=a2700.galleryofferlist.normal_offer.d_image.4a745dd9wib41C&s=p |

| 214.3 | NFT | Rack | n/V = 108/(0.96*0.5*1.05) = 108/0.504=214 | https://www.alibaba.com/product-detail/Hydroponics-Nft-System-with-108-Holes_60827073175.html?spm=a2700.galleryofferlist.topad_classic.10.44e86ededHBbuX |

| 390.6 | NFT | Wall | n/V = 45/(1.2*0.12*0.8) = 45/0.1152 = 390.6 | https://www.alibaba.com/product-detail/Hydroponic-Fodder-Growing-Systems-Vegetable-Growing_62408878165.html |

Materials

There are materials that have risks associated with them that make them unsuitable for hydroponics. See section Risks.

Safe (food grade) materials for hydroponics

Safe plastics:

- Hemp bioplastic

- HDPE (high-density polyethylene)

- PP (polypropylene)

- PVC (Polyvinyl chloride)

Ceramics

Glass

Ideally, materials should be locally sourced and designs should minimize the amount of material used.

Parts

Ideally, you want to minimize the number of parts, however, trade-offs can be made to maximize yield; a system with a pump, grow lights, fans, etc. may produce higher yields and require less maintenance than a passive (non-electric) hydroponic system.

Parts included in different types of hydroponic systems

| NFT system (Nutrient Film Techinique) (Active) | Fogponic system (Active) | Kratky system (Passive) |

|---|---|---|

| Water reservoir | Water reservoir | Water reservoir |

| Submersible electric pump | Fogger | Lid (with holes to fit net pots into) |

| Air stone (optional) | Fan (to move fog from reservoir to pipes) | Net pots (to put substrate into) |

| Pipes (to fit net pots into) | Pipes (to fit net pots into) | Substrate (to put seeds or seedlings into) |

| Net pots (to put substrate into) | Net pots (to put substrate into) | |

| Substrate (to put seeds or seedlings into) | Substrate (to put seeds or seedlings into) | |

| Tubes and fixtures (to connect pipes) |

More components can be added to achieve maximize yield and achieve automation. More details in Energy section.

Rectangular vs. round pipes in an NFT system

In an NFT system where pipes are positioned horizontally (although at a slight angle to facilitate water flow), consider the shape of cross section of the pipe.

- Space for roots

- With a round pipe of a certain width (diameter), the space for the roots is going to decrease towards the bottom of the pipe. + With a square pipe of the same width, the space for the roots is going to remain constant from the top and the bottom of the pipe.

- Balancing of plants

- With a round pipe, net pots only have their brim in contact with the center of the top of the pipe and may start leaning more and more to one side, making the plant grow lopsided. + With a square pipe, net pots have their entire brim in contact with the flat top of the pipe which can prevent the net pot from leaning more and more when a plant grows a bit more to one side.

- Spacing of seedlings

In order to save space, it is possible to have square pipes dedicated for seedlings.

+ Before a plant has grown to a certain size, they can be placed right next to each other on a square pipe. - With a round pipe, even if it's quite wide, this isn't possible; net pots can only be positioned at the center of the pipe so that the plants don't lean.

Wide vs. narrow pipes

Narrow pipes, around 50 mm, can save space and cut down on material. These are suitable for leafy greens, garnish, and spices with smaller root systems. However, there are bigger vegetable plants with root systems that require wider pipes.

Additional parts

- Grow tents (creates a controlled mini-environment for plants.)

- Plant supports (some plants grow branches that require supports to not destabilize the plant)

Energy

Ideally, you want to minimize the energy consumption required to run the system. However, a passive system (without electronics) may not be as productive and require more maintenance.

Active vs. Passive system

A passive system does not use electricity while an active system does.

The benefits of a passive system are

- fewer parts

- no power consumption required to run system

The benefits of an active system are

- higher yield

- higher quality plants

- automation

Automation and climate control optimization

Among the activities listed under Use (above), the most complicated, labor-intensive and most commonly automated is the control of nutrient levels and grow room control.

A hydroponic control system can measure and manage the yield factors via the tools listed below:

- Growing method

- Light; grow lights with the optimal frequency and distance from plants (LED lights and timer)

- Air temperature: thermometer, heaters

- Temperature in nutrient solution: thermometer, heaters

- Nutrient mix: automatic doser

- pH (acidity in nutrient solution): pH-sensor, automatic nutrient doser.

- EC (Electrical conductivity in nutrient solution): conductivity sensor, automatic nutrient doser

- Water flow: pump

- Humidity: humidifier

- Air flow: fans

- Oxygen levels in water: air stone

- Carbon dioxide levels in grow room

Open source examples of hydroponic control systems

Water

Ideally, you want to minimize water consumption. Hydroponics is already an effective way to conserve water compared with growing plants in soil.

Be aware that grey water (water from doing dishes, taking showers, etc.) cannot be used in hydroponics. It can be harmful to eat plants from grey water, therefore only white water should be used for hydroponics (clean water free from soap, fat or oil from cooking, human skin particles, etc.) Grey water is only an option if you are growing is soil, but even then it has to be done the right way with regards to selection of soap, etc. Black water (containing human waste) should never be used.

Nutrient requirements

A complete hydroponic nutrient solution contains the following elements:

- Nitrogen (N)

- Potassium (K)

- Phosphorus (P)

- Calcium (Ca)

- Magnesium (Mg)

- Sulphur (S)

- Iron (Fe)

- Manganese (Mn)

- Copper (Cu)

- Zinc (Zn)

- Molybdate (Mo)

- Boron (B)

- Chlorine (Cl)

Some beneficial but non-essential elements include:

- Nickel (Ni)

- Cobalt (Co)

- Silica (Si)

- Selenium (Se)

Managing nutrient concentrations and pH values within acceptable ranges is essential for successful hydroponic horticulture. Common tools used to manage hydroponic solutions include:

- Electrical conductivity meters, a tool which estimates nutrient ppm by measuring how well a solution transmits an electric current.

- pH meter, a tool that uses an electric current to determine the concentration of hydrogen ions in solution.

- Litmus paper, disposable pH indicator strips that determine hydrogen ion concentrations by color changing chemical reaction.

- Graduated cylinders or measuring spoons to measure out premixed, commercial hydroponic solutions.

Usability

Installation

The number of parts and their design is a factor.

Maintenance

Maintenance may include

- cleaning of pipes

- replacing parts

Use

Use involves

- putting seeds into substrate (typically a rock wool cube) for germination (the stage where plants break out of their seed shells and become seedlings.)

- transferring seedlings into net pots with substrate and putting them into hydroponics system

- dosing (managing nutrient levels in water)

- room control (managing temperature, humidity and other factors shown under automation)

- harvesting

- refilling water reservoir

Ideally, the system shall be designed to be used with ease and good ergonomics.

Risks

| Risk | Symptom | Consequence | Mitigation | Comment |

|---|---|---|---|---|

| Algae and microbe growth inside system |

Green colored water or visible clusters of green particles |

Reduced yield; damage to plants or plant death |

|

Algae requires light to grow and can be combated by limiting the amount of light that reaches inside the system. |

| Plastic contamination | Detection is not possible without lab equipment | Harm to person | If plastic is used in the hydroponic system, use food graded plastic | PVC is a common plastic used in hydroponics. If no plasticizers are added, it is known as uPVC or Rigid PVC (Food Safe PVC). uPVC or Rigid PVC does not contain any phthalates or BPA and is safe and stable. |

| Clogged pipes | Limited nutrient supply | Reduced yield | Use pipes with a wide enough diameter to fit the plants' root systems | Small leafy greens such as lettuce, can grow easily with pipes as narrow as 6 cm in diameter, but tomatoes have larger root systems that require larger pipes. Grow tower designs that have been used for tomatoes often have a diameter of 30 cm or wider. |

| Clogging of atomization nozzles orifices (in aeroponics and fogponics) | Limited nutrient supply | Reduced yield | Use pipes with a wide enough diameter to fit the plants' root systems | Use mesh filters. |