Kauffman Proposal

Progress Report, Feb. 15 2012

Note: Since the report was written, Prototype II of the Dimensional Sawmill has been completed at a cost of ~$19k total. No documentationor field testing has occurred as of 5/3/12. Documentation, CAD, data, fabrication drawings are forthcoming on all of the machines as we recruit the team.

Download copy of progress report: File:Feb15progress.pdf

Updated Proposal

December, 2011. Granted, December, 2011.

Initial Proposal, August 2011

Download: File:Kauffman Proposal 081511.odt

File:Kauffman Proposal 081511.doc

Kauffman Foundation Grant Proposal, $145k

by Marcin Jakubowski, Ph.D.

opensourceecology.org, opensourceecology@gmail.com

Abstract: We are building the Global Village Construction Set (GVCS) – a low-cost, high-performance, open source, DIY platform that allows for the easy fabrication of the 50 industrial machines that it takes to build a small civilization with modern comforts. OSE is currently building infrastructure for a Flexible and Digital Fabrication Training Facility (think of Open Source version of TechShop) at Factor e Farm, our experimental laboratory. Our goal is distributive economics – developing tools for open source, productive enterprises with a focus on training producers. We are interested in developing a new economic engine - the community-based solution of re-localized production. By this year's end, independently of this grant proposal, we will deliver the OSE Christmas Gift to the World: (1), Product Releases of Tractor, Compressed Earth Brick press, Soil Pulverizer, and Hydraulic Power Unit after completing 3 prototypes for all these machines; (2), thorough documentation of these 4 tools to make replication a straightforward reality; and (3), extensive field testing of this equipment to demonstrate efficient, high-performance construction techniques with these tools within the context of building our training facility infrastructure. The goal of this grant proposal is to prototype 8 further machines, directly relevant to our construction plan of the Digital Fabrication Training Facility. This is consistent with our core mission of developing the full GVCS enterprise platform by year-end 2012.

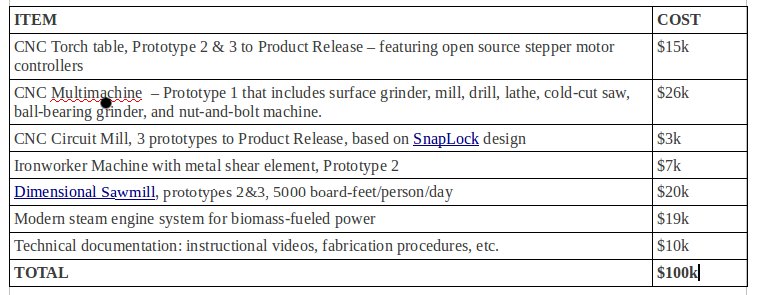

We will use the grant as follows within 6 months of receipt of funding.

|

ITEM |

COST |

|

CNC Torch table, Prototype 2 & 3 to Product Release – featuring open source stepper motor controllers |

$15k |

|

CNC Multimachine – Prototype 1 that includes surface grinder, mill, drill, lathe, cold-cut saw, ball-bearing grinder, and nut-and-bolt machine. |

$26k |

|

CNC Circuit Mill, 3 prototypes to Product Release, based on SnapLock design |

$3k |

|

Ironworker Machine with metal shear element, Prototype 2 |

$7k |

|

Dimensional Sawmill, 3 prototypes up to Product Release, 5000 board-feet/person/day |

$29k |

|

Tractor Loader-Mounted Cement Mixer, 2 prototypes to Product Release6 |

$6k |

|

Trencher, 3 foot depth, 2 prototypes to full product release |

$6k |

|

Universal Rotor, including fabrication technique for earth augers, Prototype 2 |

$5k |

|

Technical documentation: instructional videos, fabrication procedures, etc. - 2-3 full time, on-site people at Factor e Farm, 6 month duration at $8k/month |

$48k |

|

TOTAL |

$145k |

Significance

The tools above are a continuation of GVCS prototyping – open source solutions contributed to the world. We are addressing two areas. First are construction needs (brick production, lumber milling, and cement mixing, plus others). This, combines with our tractor infrastructure, allowing one to bootstrap infrastructure building at $5/sq ft construction cost for shell structures – while remaining within industry-standard construction schedules. Second, we are providing powerful fabrication tools: CNC torch table for automation of parts cutting; CNC Multimachine for producing otherwise expensive components such as hydraulic motors for the tractor and even bolts and ball-bearings; circuit mill for producing circuits, such as microcontrollers. We are also including the ironworker machine for cutting and punching 1” thick steel. These tools can also make replicas of themselves with the hands of a skilled operator.

For the purposes of enterprise creation – we expect the following materials costs for building the machines above, as compared to industry standard costs for purchasing equivalent machines off-the-shelf.

-

ITEM

MATERIALS COST

OFF-SHELF

COST

CNC Torch Table

$2.5k

$40k

CNC Multimachine

$5k

$45k

CNC Circuit Mill

$600

$4k

Ironworker Machine

$2k

$21k

Dimensional Sawmill

$3k

$35k

Cement Mixer

$700

$6.7k

Trencher

$700

$5k

Universal Rotor

$700

$5k

TOTAL

$15k

$162k

The difference between materials cost and off-shelf cost represents the potential value captured by local enterprises. For the purpose of community infrastructures, this represents significant generation of wealth on the local level.

Outcomes

We will produce the 8 physical machines above (some have multiple prototypes). For each machine, we will also include the following: (1), design rationale; (2), 3D CAD files; (3), 2D fabrication drawings; (4), CAE analyses; (5), CAM files for the circuit mill, torch table, and CNC Multimachine; (6), exploded part diagrams; (7), Bills of Materials and sourcing information; (8), scaling calculations; (9), A-Z instructionals; and (10), cost and performance comparisons to industry standards. In general, we are predicting 8x cost reduction compared to industry standards, reducing the barriers to entry of enterprise startups.

Deployment Strategy

We will go through design review with the local fabrication shop to produce the (1), sawmill, (2), cement mixer, (3) trencher; (4), universal auger; and (5), ironworker machine. The local fabrication shop is well-suited for building these prototypes, as we have been working with them for the last 4 years.

For the CNC Multimachine, we have recruited an on-site machinist/machine designer. For the CNC torch table, we will build on our first successful prototype and leverage the existing hackerspace community for a torch table hackathon. For CNC circuit mill, we will build on the open source work of MIT – SnapLock - to optimize the circuit mill toolchain for effective circuit production of surface mount circuits.

We will test the construction/utility devices rigorously in field conditions in our 2011 construction at Factor e Farm - where we will build the 5000 Square Foot Fabrication Training Facility and 6 living units for trainees.

The documentation aspect is a significant portion of the work. The documentation team will be involved deeply in the development process. This team will live on-site, documenting the process and results. The skills required include video editing, technical writing, and an ability to edit on daily publishing schedules. This will take us closer to defining a replicable template for professional documentation standards of the entire GVCS.

Overall Budget for OSE Until 2013

The mainstay of our funding to date has been the True Fans – micro-funding, private donations from individuals at $10/month to the project. We currently have about 400 True Fans, for a monthly donation budget of $4k. We spend all of this directly on prototyping at Factor e Farm as soon as the money comes in with 100% volunteers at present, with low overhead at an off-grid facility where we dogfood the technology.

We are currently organized as an unincorporated project under the fiscal sponsorship of Terra Foundation of California – a public charity that handles any nonprofit donations. We have done no resource development, but have gotten one $60k donation offer for infrastructure building from an anonymous donor. Moreover, we just shot footage for a Kickstarter to go the 'last mile' with the OSE Christmas Gift to the World mentioned in the Abstract. The Kickstarter goal will be $40k, and we aim to kick off this campaign in 2 weeks. Also, I will be applying for $250k project funding from the Shuttleworth Foundation for a Fellowship that starts in March, 2012.

Our overall budget goal is $4-5M to complete the GVCS bear-end 2012, so that the entire platform can be completed and put to the test in terms of creating community-based solutions of re-localized production consistent with our principles of distributive enterprise. Approximately 50% of this budget is for proper documentation. Our experiment aims to demonstrate the feasibility of creating complete, technologically-advanced economies from 100% local resources (trade is optional). We aim to obtain data points on the limits of what individual communities can do to transcend artificial scarcity. We will carry out this social experiment at Factor e Farm – a community of 200 people - between 2013-2014 - just one hour away from Kansas City.