Keyline Plowing

Jump to navigation

Jump to search

Basics

- The Subsoiling / "Subsurface ripping" of topsoil along Keylines to allow for increased Water Infiltration

- Essentially forms slits or micro trenches perpendicular to water flow

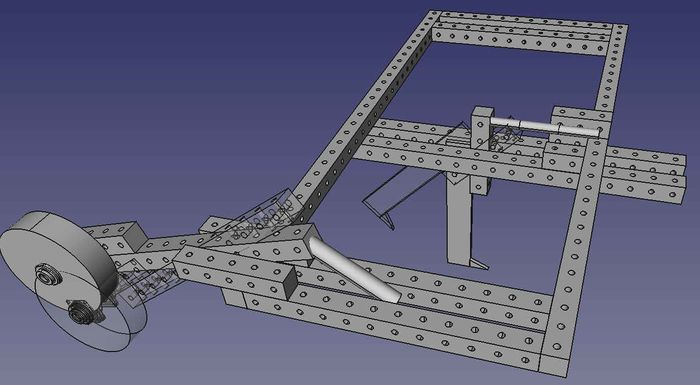

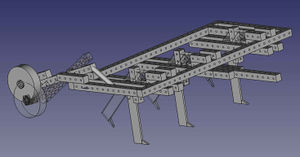

OSE Keyline Plow with Hydraulic Release

(note: wheel shown on one side only, other side is identical. Lifted position of keyline shank is shown. Cylinder by the shank represents the hydraulic cylinder that provides the release to the shank)

.

Design Rationale

- Modular wheels

- Raisable wheels

- Hydralic cylinder with pressure relief (not hydraulic accumulator) is used for release

- Valve operated return-to-soil via control valve in cab

- 3' shank length total, 2' depth max

- Shank release angle is 45%, using an 3"x8" hydraulic cylinder

- 1" pivot through box beam tubing serves as shank pivot point

- Shank is welded to 12" of box beam tubing

- Height adjustment occurs via hydraulically lifted wheels, or via adjusting height via pin on the box beam tubing

- Designed around Universal Drawbar

- Designed for up to 4 shanks at 2' spacing

- Extensible in width by adding more box beam tubing

- Modular coulter wheels are attachable in front of shanks

- Designed for carrying fluid (water, compost tea, etc) on top of frame.

- Idler wheels can be doubled for a total of 6400 lb load capacity on wheels (1600 lb each wheel)

- Wheels are car donuts with two 1-7/8" bearings

- Shank is 1"x6" mild steel

- Tip should be welded with tungsten powder

Suggestions and Comments

Links

- Winged tip vs conventional tip subsoilers - [1]

- Yeomans discussion - soil can be built up with keyline plowing faster than it can be eroded

- Graham chisel plow from last link:

- Next