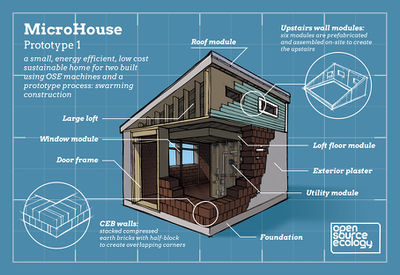

Module Breakdown - MicroHouse

Concept

The MicroHouse is broken into modules to enable a social production model like all OSE machines/architecture.

Foundation Module

Development

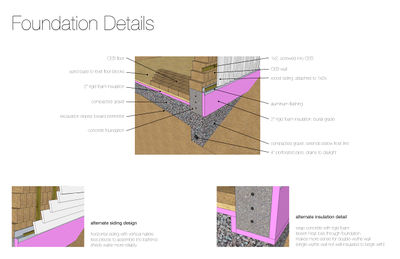

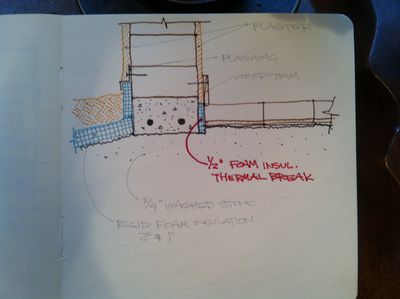

This early drawing explored a stemwall idea for the MicroHouse foundation and looked at various ways of insulating the foundation and siding the building.

Marcin was very interested in continuing to experiment with the shallow insulated footer concept. Here is a drawing based on design discussions between Floyd and Marcin. More information about the shallow insulated footer concept can be found here.

Based on conversations with Walter Grondzik, PE... One item we discussed was getting the best performance from the direct solar gain heating system (heating of the CEB floor by sun shining through windows). Walter highly recommended putting in a thermal break between the floor and the foundation. Without this break, there heat will travel easily from the floor to the foundation. He suggested a 1" thick piece of foam, but he agreed that a 1/2" piece would be acceptable. Even at 1", the plaster and a trim board would cover it.

Here was the initial idea for foundation formwork, discarded in favor of the simpler, faster idea presented below in Execution Section below.

Execution

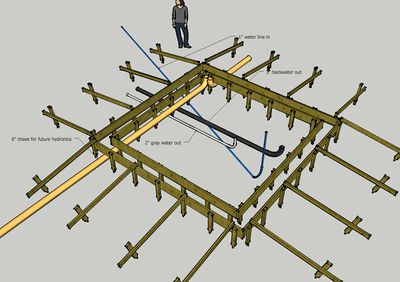

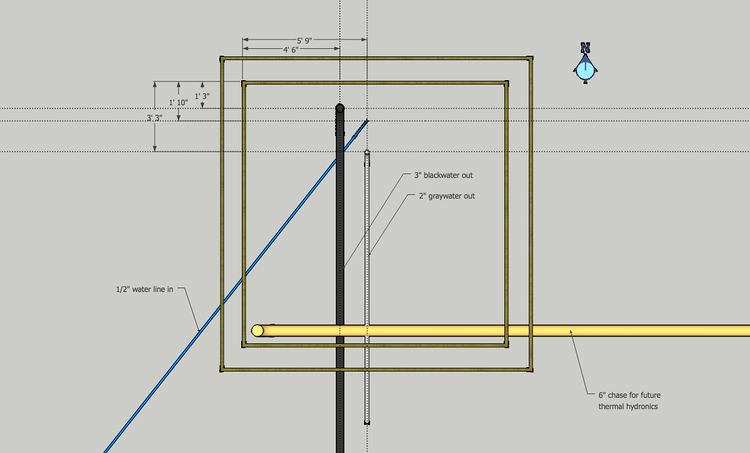

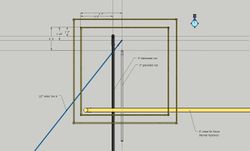

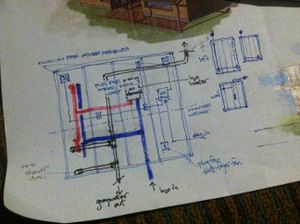

Precise dimensions for pipe layouts

Notes:

1. Measure and mark opposing interior form boards with dimensions listed.

1a. Measure from outside of inner form board (in other words, from what will be inside of concrete).

2. Put small nail into form top at location of mark - string between similar mark on opposing form board.

3. Run designated pipes under foundation formwork and make sure vertical pipe is directly under

proper intersecting strings.

4. 6" chase for future hydronics does not need to be at any slope.

5. 2" graywater and 3" blackwater lines MUST BE AT 1/4" slope per 1' of length.

This is required for proper drainage, otherwise liquids will outrun solids.

6. Pipe layout shows 6" chase running over 2" and 3" lines, however, it is typical to conserve as much

elevation as possible when exiting graywater pipes... best practice will be to run 2" and 3" pipe

out just below bottom of foundation formwork. 6" pipe will most likely run beneath level of 2" and 3" pipes.

7. Run pipes past foundation forms by roughly 5' and cap with cardboard/duct tape or old rag, etc.

Leave vertical pipes at a length of 1' taller than foundation forms. Cap this end, as well.

Staking the vertical pipe in place with rebar will prevent it from getting disturbed.

Pipe Elevations:

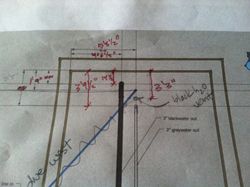

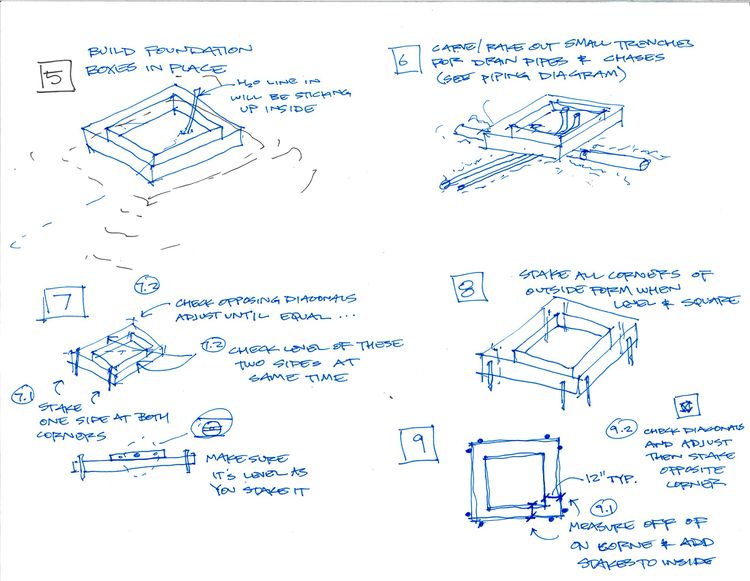

Instructions Sketches

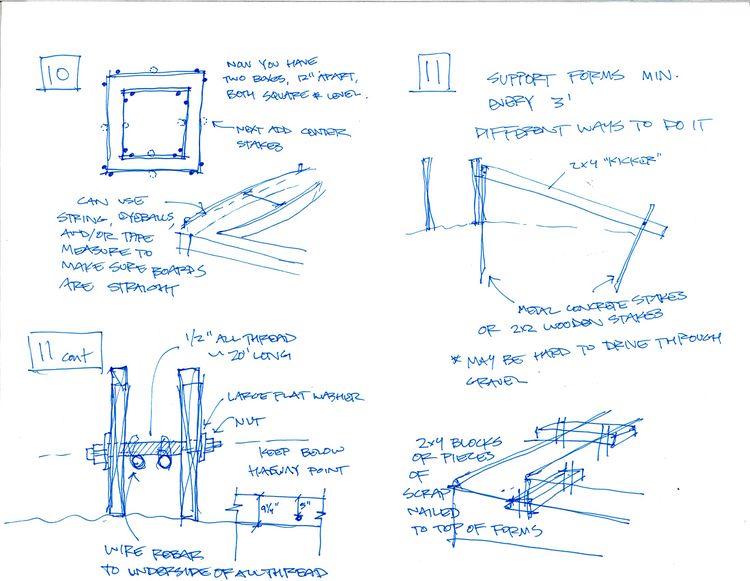

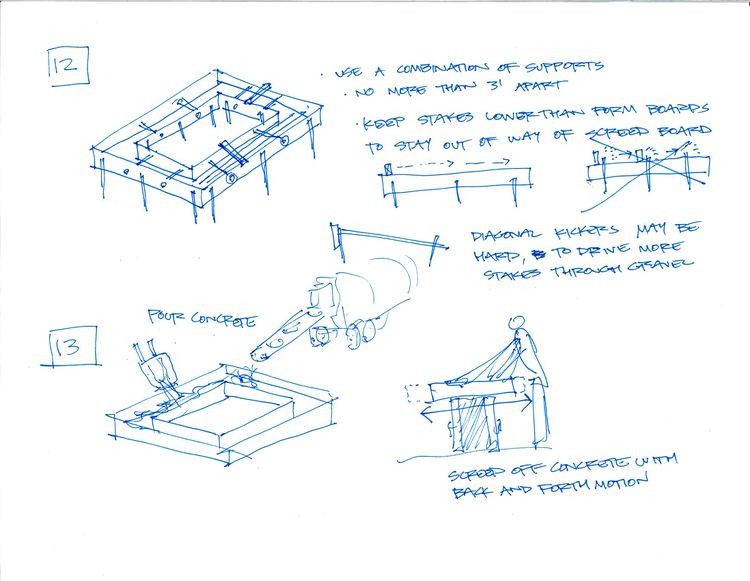

For allthread, do 2 at corners and 2 in middel - 4 per side. For blowout, do 2 of them per side - 1/3 way each. Rebar ends up at bottom 1/3 of boundation. Allthread about 5 inches down from top.

Stub out 8-12" of rebar.

Do 4 pieces of allthred per side -

Build Documentation

Assembling the MicroHouse foundation forms:

Pouring the concrete for the MicroHouse foundation:

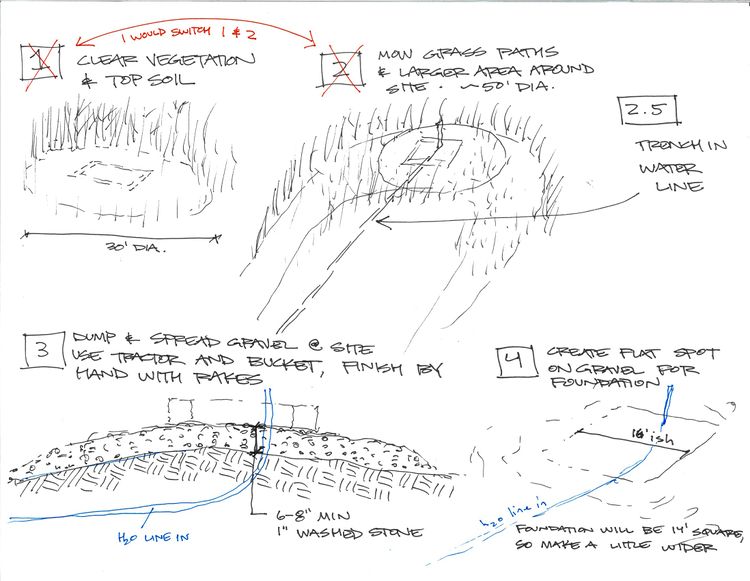

Next, we installed the drain pipes, water inlet and the chase to enable thermal hydronics to connect to a future module.

Having proper fall on drainage pipes is essential. In order to facilitate measuring the fall on drain pipes at 1/4" per 1', a small 1" jig is taped to the end of a 4' level.

Strings were attached to the foundation form boards; intersections show where pipes come through floor. Final dimensions shown on marked up sheet to make any adjustments needed to utility module.

3" blackwater pipe was installed first. Gravel was dug out, pipe was put in place and checked for proper fall. "Shit runs downhill," the old plumber's golden rule says, but it runs downhill best if it sloped at 1/4" per 1'. Too much fall, and liquids can outrun solids.

Always prime pipe before gluing to ensure a good bond. The vent pipe for the blackwater outlet (not shown in original drawing) penetrates the floor to come into the utility module. String intersections were used as guides and pieces were held in place to determine pipe lengths for cutting.

Once the 3" pipe was in place, a similar trench was dug out for the 2" line using the string as a guide. Here, the 2" and 3" lines are shown exiting the building. Both were kept low enough that the 6" line can go above them.

The last pipe to go in was the 6" chase that will eventually contain insulated PEX pipes to carry thermal energy to a future module. The 90 was too tall, so one of the bell-ends was cut off of it. Once the pipes were installed, the ends were capped with plastic bags and duct tape to avoid debris getting inside them before use.

The end result... pipe stubs right where we want them to be!

CEB Wall Module

Window/Door Module

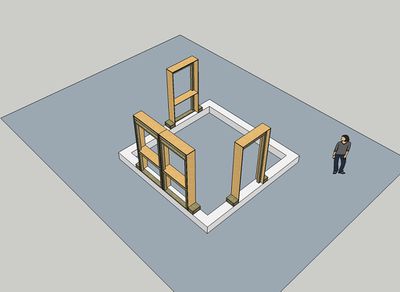

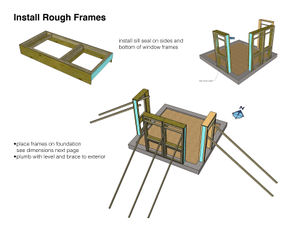

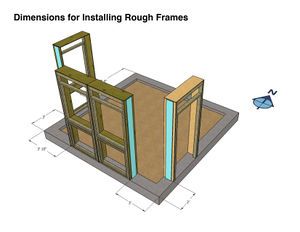

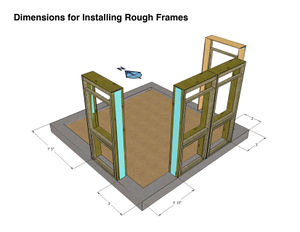

The window and door modules provide openings in the CEB wall structure and provide openings and rough framing to easily insert standard window and door units. The goal was to create floor to ceiling units that bricks can be stacked on either side of, rather than units that are embedded in the CEB wall itself. This design requirement was set by Marcin based on his previous experience with inserting rough window and door frames into CEB walls, and the added time that that approach took.

Development

Initial ideas for window and door frames, as well as a gringo block for attaching frames and a block for service entrance of data and electricity.

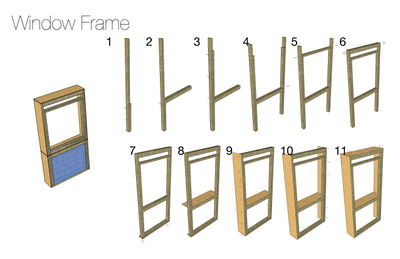

Here is a first pass at creating an instruction sheet for how to build a window frame module:

This image shows the first idea of how the frames will set on the foundation. Marcin did not want to use gringo blocks for attachments as it seemed redundant to him, so the design was simplified. Rather than secure the frames to the foundation, the frames will be secured to to the CEB walls with numerous screws.

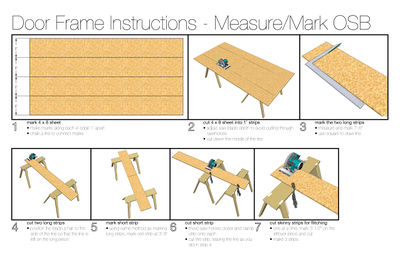

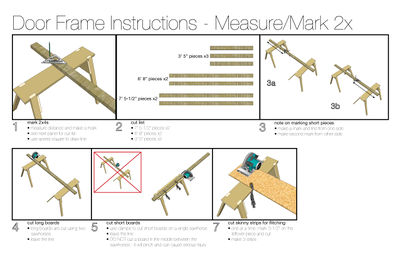

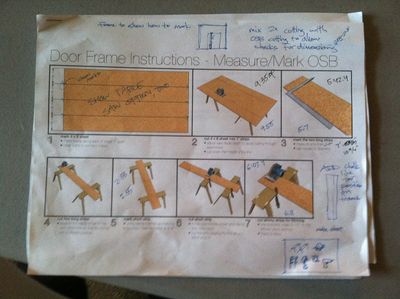

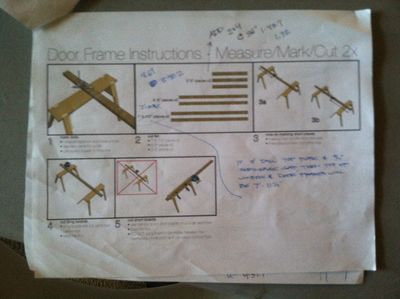

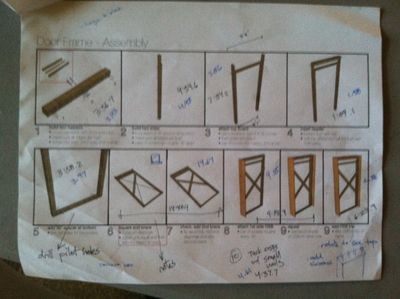

Next iteration of instruction sheets for door/window frame building. This is much more detailed, but sheets like this take a long time to create. This sheet was created before the use of the Dozuki platform was in full swing (or at least before I was aware that it was being used). -Chris

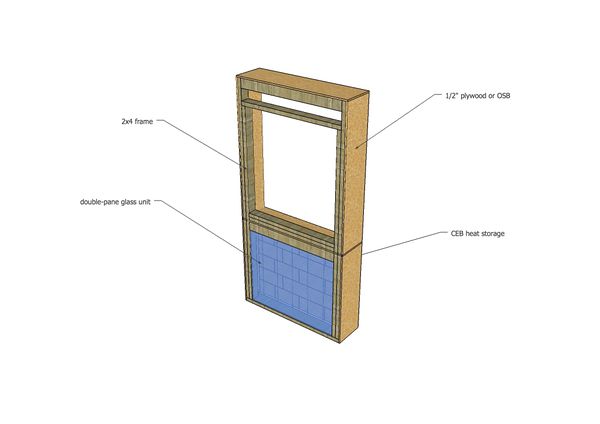

Final window frame design includes both a direct passive gain component (the upper, window portion), and an indirect gain component (the lower, trombe wall portion). The design was review with Walter Grondzik, PE, and he thought it was sensible. He did comment about air-sealing the building in general, though, a critical component when maximizes passive gains. He liked the idea of using a foam gasket (referred to often as "sill seal," in the field) between the window and door frames and the blocks stacking up next to them. Also, between the block wall and the top plate.

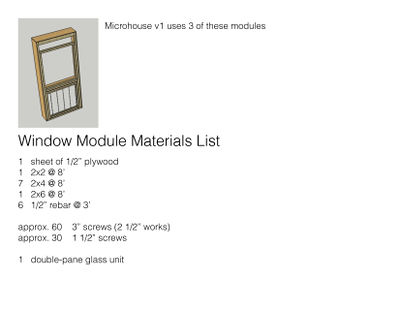

Materials List for Window Frame:

For the final build, we did not use the rebar shown in the model. Its intended purpose was to prevent the bricks from accidentally being knocked into the glass pane unit, but upon construction it felt stout enough to leave that extra layer of protection out. Also recommended in the future is the use of thicker sheet material. The 1/2" plywood had a significant amount of wiggle in it, making the trim-out of the interior much more difficult than it needed to be. 3/4" sheet material would provide a much straighter surface for finishing.

Here are the final instructions used for erecting the rough frames on the foundation:

Execution

Build Documentation for Window Frame

MicroHouse 1 uses three of the window frame modules.

Build Documentation for Door Frame

An intern at OSE, Lucas, and I built the first rough door frame from the instructions I had created. We timed each step of the process, and also marked up the instruction sheet for the second iteration. All pictures can be found on trovebox under the tag "microhouse."

Make sure that the rough opening used for the door and window frames fits the rough opening that your actual door and windows needs. The R.O. needed for the door we ended up ordering was larger than this one, so we had to modify it later to accommodate the door.

Utility Module

Development

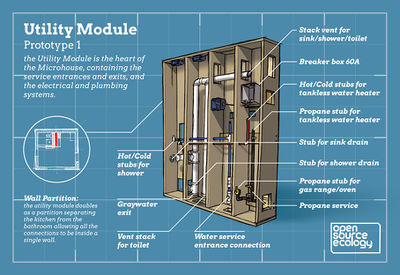

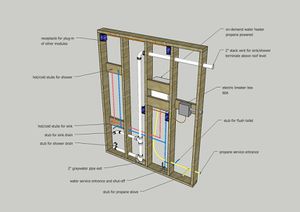

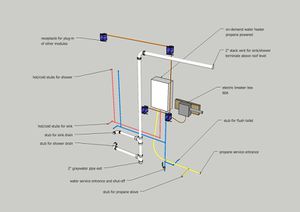

The idea of the modular components for the mechanical and electrical system has evolved into the module being one of the partition walls in the building itself. This wall will contain the electrical and plumbing connections of the sink, shower, toilet, stove, and electrical receptacles. The utility module wall will also support the loft panels. Loft panels will be pre-wired for electrical connections, and will plug in to receptacles on the electrical module-wall.

Here, one can see how all the appliances back up to a single interior wall along with the initial schematic drawing of the Utility Module.

Here is an image of the SketchUp model created based on the schematic diagram, shown with and without framing.

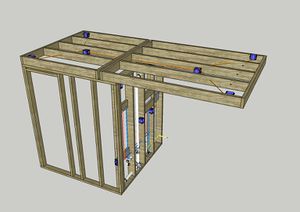

Here we see how the utility module interfaces with the other interior wall module and the two loft modules, again seen with and without framing. The final design kept only two receptacles in the loft, the ones on the smaller loft module located on the west.

The Utility Module interfaces with the rough-in stubs for the plumbing, so their proper placement is critical. See Precise Dimensions for Pipe Layouts for more information.

Execution

Utility Module, as-built in workshop. Note the extra vent pipe as compared to the 3d model. The additional vent pipe services the toilet, which is plumbed underneath the floor. See Build Documentation for Plumbing.

Partition Wall Module

This module creates a dividing wall between the living area and the bathroom. It also helps to support the loft module placed above it.

Loft Modules

The loft modules create living space above the kitchen and the bathroom.

Upper Wall Modules

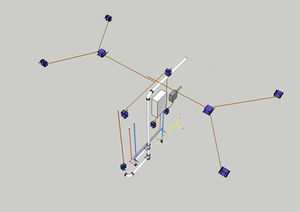

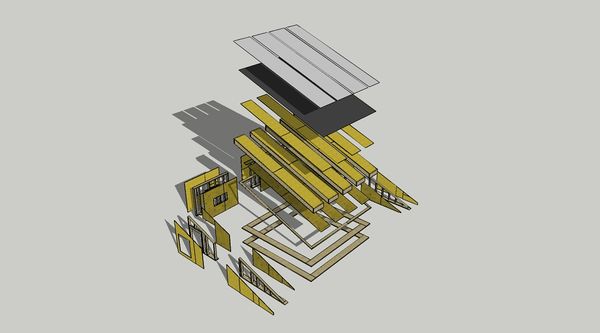

Exploded diagram of upper wall modules and roof modules:

Roof Modules

The roof modules allow the roof to be constructed rapidly and without requiring tight tolerances for the placement of many parts.

Skin Modules

The skin modules protect the inside and outside of the building.