Marlin Bed Temperature Overshoot

(Redirected from PID Autotune)

Jump to navigation

Jump to search

Data

- SSR - 5 hz max reliable switching frequency. [1]. 0.5 hz recommended for heating.

- Overshoot is 10-30C on the bed. D3D_v20.04.27_Data_Collection#Hysteresis_of_Bed

Code

- M303 S50 E-1 C5 - 5 passes, set for 50C, -1 for bed

Procedure

PID Autotune - [2]

Results

Extruder

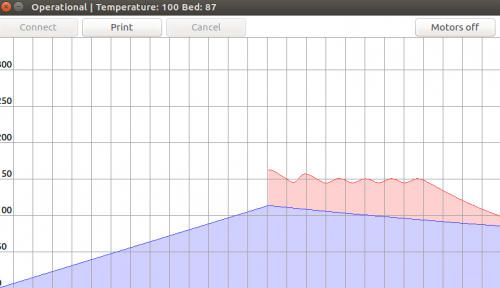

Using Lulzbot Cura, M303 with no parameters heats the extruder to about 150. Each time division is about 30 seconds:

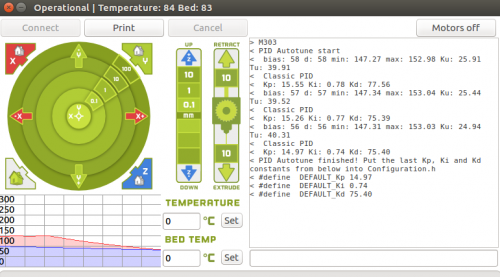

And produces optimal values of P, I, D

M503 displays current values:

< M503

...

< echo:PID settings:

< echo: M301 P22.20 I1.08 D114.00

You can save the values from PID Autotune by going into configuration.h

Bed

- PID autotune would have to be enabled for the bed in configuration.h.

- If one is using an SSR, can this be used with default switching frequency of Marlin? Let's look inside Marlin - Configuration.h

- SSR heats up when conducting via voltage drop. The switching doesn't cause much heat. [3]. See SSR Lifetime. It is not clear if fast switching (only 8 hz) reduces lifetime over say 4 hz in PWM switching?

- Start by turning on PID for the bed: uncomment #define PIDTEMPBED in configuration.h

- SOFT_PWM - sets PWM frequency?

- Can also add PID autotune to menu via configuration.h: //#define PID_AUTOTUNE_MENU // Add PID Autotune to the LCD "Temperature" menu to run M303 and apply the result. But does this save the result?

- Configuration.h can also use slow PID - //#define SLOW_PWM_HEATERS // PWM with very low frequency (roughly 0.125Hz=8s) and minimum state time of approximately 1s useful for heaters driven by a relay

- M500 should work in Cura to save PID settings, or Save Settings in LCD? Or save in configuration.h for the common OSE characteristics.

Errors

> M303 S50 E-1 C5

< PID Autotune start

< PID Autotune failed! Temperature too high

Failed once bed reached 70.

Links

- Marlin software - PID autotune - [4]

- RepRap wiki - [5] - how to set values manually - understanding the proportional, integral, derivative terms.

- D3D_v20.04.27_Software - Marlin change log