PV Panel Grounding

NEC 690 - Covers PV Systems

- 690.41 - Equipment Grounding Conductor requirements [1]

- 690.41(B) also requires ground fault protection except if there are no more than 2 strings (PV source circuits [2])

- Since NEC 2020, ground fault indicator must be readily visible (but not necessarily readily accessible?) [3]

- 690.45 - size of PV equipment grounding conductors - Table 250.122 + no less than 14 ga.

- 690.41(B) also requires ground fault protection except if there are no more than 2 strings (PV source circuits [2])

- 690.9(A) says that we don't need overcurrent device for PV if the wires can handle short current capacity of PV. But good luck trying to convince a code official.

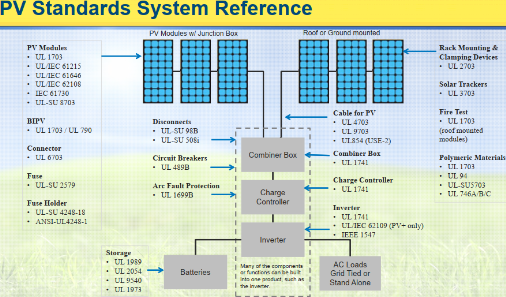

PV Grounding PDF [4]. Although the NEC does not specifically require all equipment to be certified/listed, many local jurisdictions and many AHJs establish requirements that all equipment be certified/listed because they feel unqualified to examine uncertified/unlisted equipment for safety as the NEC requires.

PV Grounding PDF [4]. Although the NEC does not specifically require all equipment to be certified/listed, many local jurisdictions and many AHJs establish requirements that all equipment be certified/listed because they feel unqualified to examine uncertified/unlisted equipment for safety as the NEC requires.

- Good overview doc. Read it from p. 6 on to understand equipment ground, system ground.

- Additional issue for PV is that in cloudy conditions or when there is little sun (evening), if you get a fault, a breaker may not trip because current is too low. For this reason, specific ground fault protection is required. But, if it's a fuse to solid ground from - of PF to ground rod - why not just use a lower value fuse? I don't get it.

- Is earth ground of a PV system connected to DC negative, or to AC neutral?

PV Frame Grouding

Homepower Article

Homepower article - 1999 - [5] A grounded conductor is a conductor that normally carries current and is connected to the earth. Examples are the neutral conductor in AC wiring and the negative conductor inmany DC systems. An equipment-grounding conductor is a conductor that does

Homepower article - 1999 - [5] A grounded conductor is a conductor that normally carries current and is connected to the earth. Examples are the neutral conductor in AC wiring and the negative conductor inmany DC systems. An equipment-grounding conductor is a conductor that does

not normally carry current (except under fault conditions) and is also connected to earth. A grounding electrode conductor is the conductor between a common single grounding point in the system and the grounding electrode.

- NEC section 690 requires that ungrounded conductors in any electrical system have overcurrent protection and disconnects. Thus, if you ground the current carrying conductor, the number of overcurrent protection devices is cut in half (grounded conductor needs no overcurrent protection). This is better for system performance because each overcurrent device has a small parasitic loss.

- Inverters make less RF noise if grounded.

- Equipment grounding conductors for PV must be sized for 1.56x Isc. Seed Eco-Home 4 has Isc=24A after combining, therefore ga 10 wire can be used on each of the 3 strings, and even after the combiner, as 90C ampacity of 10 ga wire is 40A.

In summary, the equipment-grounding conductor should be as large as the current-carrying conductors in PV source and PV output circuits. In other circuits, follow NEC Table 250-122.

In summary, the equipment-grounding conductor should be as large as the current-carrying conductors in PV source and PV output circuits. In other circuits, follow NEC Table 250-122.- The connections and wiring for the equipment-grounding conductor must be continuous to allow fault currents to properly operate overcurrent devices. Removal of a piece of equipment for servicing must not interrupt the equipmentgrounding system for other equipment.

- Generally, module frames are made of anodized aluminum. The anodized coating or aluminum oxide that forms on aluminum surfaces is a relatively good insulator. This is why

listed PV modules have a special point marked for connecting the equipment-grounding conductor. A stainless steel screw is usually supplied which helps to ensure a good electrical connection.

throughout the system (PV array and subarray, battery, etc.), an insulated bus bar usually must be added. This is used to make the connections for the unswitched, grounded conductor running through the switch enclosure or subpanel.

conductors and the grounding electrode conductor is made only at one point in the system. This is known as the system ground. This single-point connection is usually made in a power center and is shown as the bonding conductor in Figure above

conductor. But this bus bar is sometimes grounded to the enclosure, presenting the opportunity for an inadvertent second grounding of the conductor that is intentionally grounded elsewhere in the system. Insulated, or ungrounded, bus bars should be used in these devices to prevent that second ground connection

- Consider that Running all grounding conductors to a common point inside

the building may increase the potential for damage from nearby lightning strikes - so think about lighning when routing additional EGC wires.

PV Fuses

- Special characteristics: high V (larger strings), more cycling (clouds), high temp, [6]

- Regular fuses do this if: they are high V, they are in a controlled environment, and low cycling

- These conditions are met indoors, with 600V fuses, and low cycling of ground faults (once per lifetime of system). Thus, the solid-ground based ground fault protection fuse can likely be a regular fuse, fast acting preferred.

- Expensive

- Fast acting as long as there are no major inductive loads on the system, otherwise these should be slow-acting because PV panels are voltage and current limited.

- Low fault current acting, high voltage fuses - 0.5 - 1A is fine.

- KLKD $12 - [7]

- DMM 1/2A fuse - [8]

- Fuse rating should bd 1.56*Isc and 1.2x for the voltage [9]

- Standards, p6 - BS alert. PV rating means that a fuse is tested to run at 1.45x the nominal current. Ok, but there is already a 1.56 requirement for these fuse sizes - why another 1.45? [10]

- BS alert: there is 'low leakage current functionality' for pv fuses - but why not just use a smaller fuse rating for lower current?

Ground Faults - System Grounding Howto

- Article says that a common ground fault protection device (GFPD) is a fuse to ground - [11]

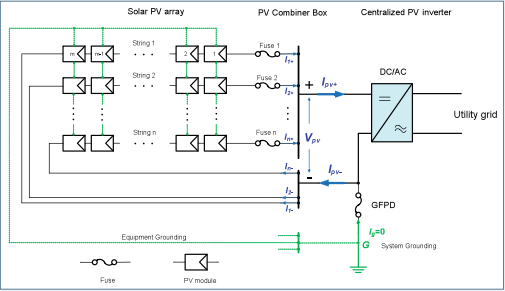

- NEC Article 690.41 states that grounding for photovoltaic systems includes 2 grounds [12]:

- The first one is system grounding: the PV system with system voltage over 50 volts should be solidly system-grounded.

- The other one is the equipment grounding: the exposed non-currentcarrying metal parts of PV module frames, electrical equipment, and conductor enclosures should be grounded .

- System Ground Howto: To achieve that, the negative conductor usually is grounded via the GFPD in the PV inverter at point G [13]:

Source: [14]

More

Solar PV standards and certifications - [15]. Class II means frames grounded, no system ground.

Solar PV standards and certifications - [15]. Class II means frames grounded, no system ground.

Paper on PV grounding, 1984. Fire safety and personnel safety are typically tradeoffs? [16]

Paper on PV grounding, 1984. Fire safety and personnel safety are typically tradeoffs? [16]

- Solidly grounded means neutral is connected to earth electrode. [17]

- Class II system had double insulation and equipment ground, but no earth connection.

- Class I has equipment ground and earth connection.

- Insulation failures between current-carrying conductors and the ground are known as ground faults.

Classic video by Mike Holt. Equipment Grounding + system grounding - Ground and grounding electrode conductor basic with Mike Holt - [18]

Classic video by Mike Holt. Equipment Grounding + system grounding - Ground and grounding electrode conductor basic with Mike Holt - [18]

- Do not earth ground frames with a ground rod like this - [19]

Equipment Grounding

- PV panels should follow electrical grounding conductor sizes - [20]

- Ie, for 30A DC, we need 10 ga ground.

- PV frames must be connected to PV system equipment grounding conductor [21]

- After leaving the PV array, the equipment ground must run together with the power wires. [22]

What Size Grounding Conductor on PV Panels?

- Australia rules - appear to say 6 ga for lightning protection, and 12 ga for frame grounding [23]

- 6 ga USA if 'subject to damage'?