Pendulum Clay Crusher

Jump to navigation

Jump to search

Intro

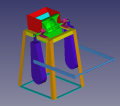

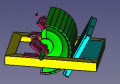

FreeCad version modeled by Aidan

http://img.youtube.com/vi/-XrflpPwegA/default.jpgVideo of Parry Building Products Version available for sale on their website

Description

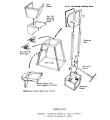

From Soil Preparation Equipment, A Publication of the Deutsches Zentrum für Entwicklungstechnologien - GATE, a Division of the Deutsche Gesellschaft für Technische Zusammenarbeit (GTZ) GmbH - 1991. Available at the Humanity Development Library 2.0. NZDL.ORG Link.:

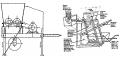

The ITW Pendulum Clay Crusher is designed to meet the needs of small scale product manufacturers, such as brickmakers. The machine crushes, grinds and screens dry lumps of clay (or shale, laterite and friable rock), producing a fine powder, which can then be easily turned into a smooth malleable clay by the addition of water. The resulting clay will be free of lumps and ready for moulding into high quality bricks or other clay products. The clay is disintegrated between a flat static plate and a semi-circular, reciprocating, hardened steel crusher head, which works on the pendulum principle. The role of the pendulum is to accumulate and store inertia, enabling the machine to function effectively with a small manual power input. An optional bolt-on conversion kit to electric power is also available. The power input is less than 1 kW. Operating the ITW Pendulum Clay Crusher To operate the machine, the pendulum is gradually swung manually by pushing and pulling the (removable) handle, or electrically with the bolt-on electric motor. The raw material is shoveled into the feed hopper above the crusher head. In order to reduce the worker's effort, an easily accessible platform can be provided at a suitable height next to the opening of the hopper. The moving crusher head entraps and breaks up the clay lumps as the head rotates in a downward direction. Ground clay falls through by gravity onto a built-in oscillating screen, which can be of any desired mesh size. On the upward return move, any remaining clay is cleared from the grinding surfaces prior to the next downward swing, so that a slight dampness of the clay is not a major problem. The ground and screened clay is collected in a wheelbarrow, which fits into the enclosed space below the screen. Rejects from sieving accumulate on the other side of the machine and can be returned to the feeder hopper for renewed crushing. The only servicing necessary is occasional greasing of the bearing of the pendulum, and from time to time inspecting the the machine for wear.

Other Links

Small Scale Manufacture of Stabilized Soil Blocks. See

- http://www.nzdl.org/gsdlmod?e=d-00000-00---off-0cdl--00-0----0-10-0---0---0direct-10---4-------0-1l--11-en-50---20-about---00-0-1-00-0--4----0-0-11-10-0utfZz-8-10&a=d&c=cdl&cl=CL1.60&d=HASH0194ef8f4e437a8c0ab0aa70.6.2.3

- http://www.nzdl.org/gsdlmod?e=d-00000-00---off-0cdl--00-0----0-10-0---0---0direct-10---4-------0-1l--11-en-50---20-about---00-0-1-00-0--4----0-0-11-10-0utfZz-8-10&a=d&c=cdl&cl=CL1.60&d=HASH0194ef8f4e437a8c0ab0aa70.6.2.4

FreeCad File

Available Downloads:

- Simple FreeCad File

- A2+ Assembly (4mb .zip download)