PowerCube6 Fuel Tank

Jump to navigation

Jump to search

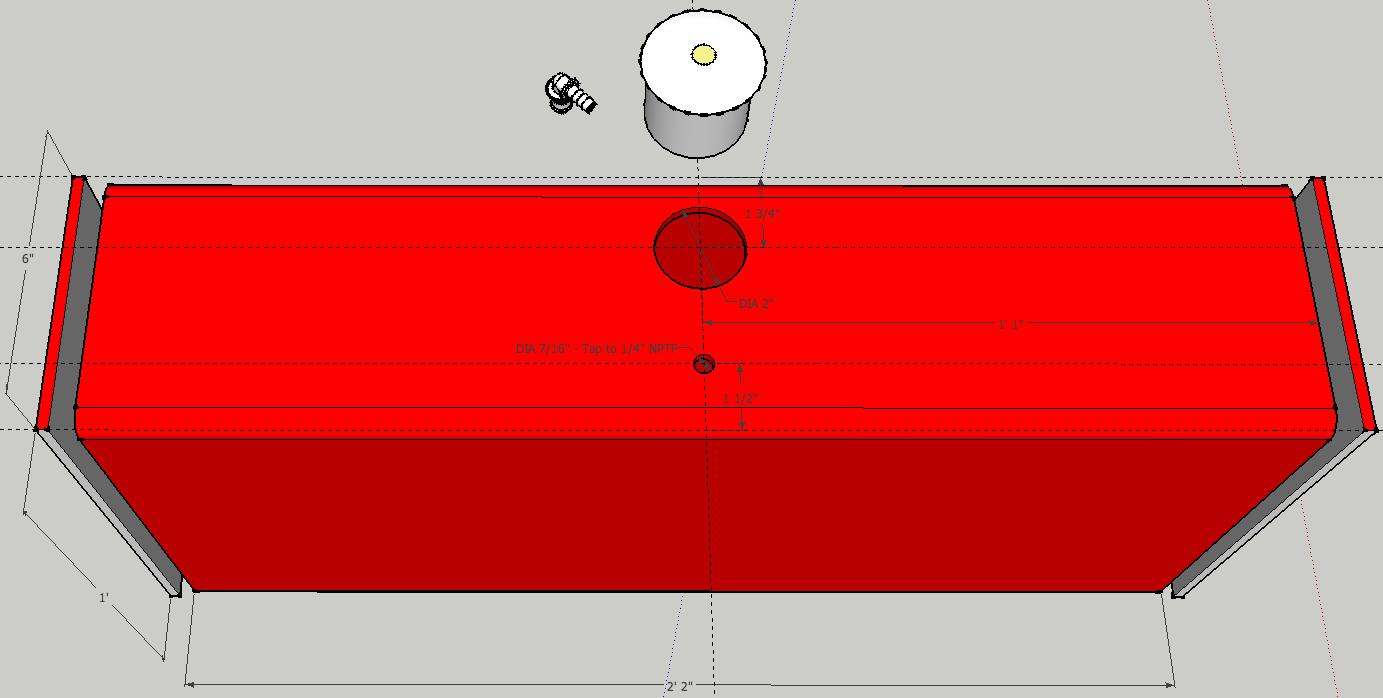

Procedure for fabricating the fuel tank. Note that the preparation of the edges for welding is critical, as the welded seams must prevent fuel leaks.

Part List:

Rectangular tube: 1/4" x 6" x 12" - 26" long [2] Flat Steel: 1/4" x 6" x 12" Weld-in Fuel Filler Neck and Cap Small sheet plastic Fuel Pickup Adapter 1/4" rubber hose Soapy water

- Grind the 1/4" x 6" x 12" plates, rounding the corners to 1/2" radius and beveling the edges for welding.

- Grind the 1/2" x 6" x 12" Tube, beveling the edges for welding.

- Cut the 7/16" and 2" holes in the tube as shown. The larger hole may be cut with an Oxy/Acetylene torch, then smoothed with a grinder. Note that the inside of the hole should be 2" in diameter.

- Weld the plates to the ends of the tube

- Tap the 7/16" hole for 1/4" NPTF threads, smooth the welds with the grinder.

- Pressure test the tank by covering the filler neck with a plastic sheet, then securing the cap. Secure the smaller hole with a the fuel pickup and some 1/4" hose on the hose barb. Apply compressed air to the end of the rubber hose to pressurize the tank, then apply soapy water to all welds and check for bubbles.

- Mark any bubbling spots with a felt-tip marker and re-weld

- Re-test the tank and re-weld as necessary to stop all leaks