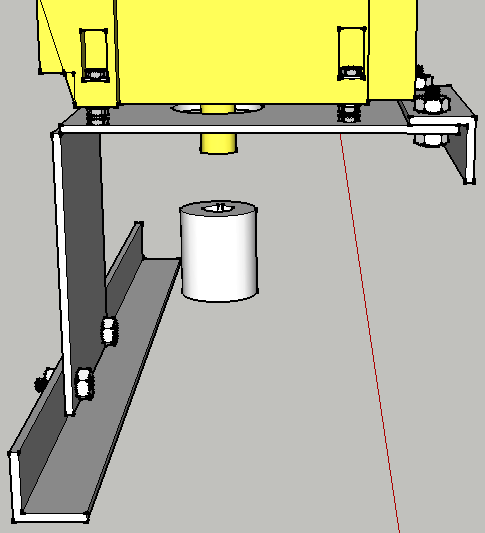

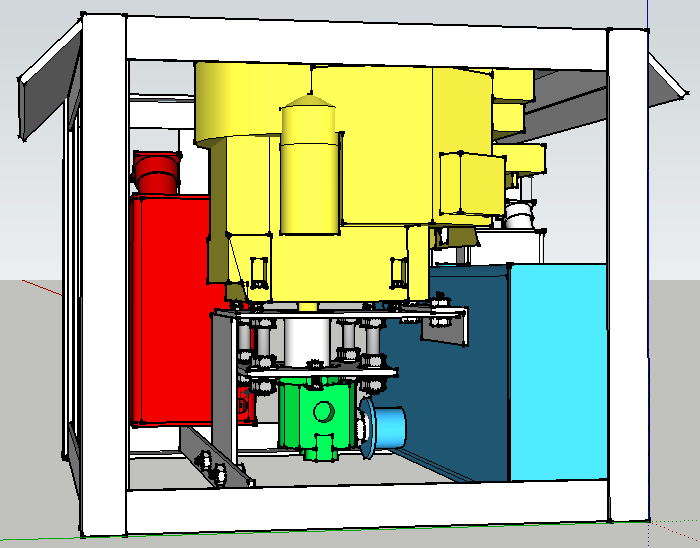

PowerCube Engine & Hydraulic Pump mounts

Jump to navigation

Jump to search

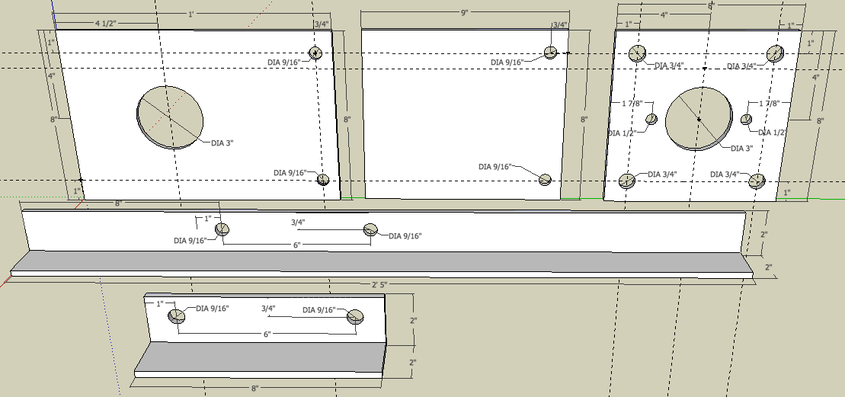

Engine Mounting Plates

- ¼” x 8” x 12” Plate

- ¼” x 8” x 9” Plate

- ¼” x 8” x 8” Plate

- ¼” x 2” x 2” x 8” Angle

- ¼” x 2” x 2” x 29” Angle

Torching of engine mounts:

And, torching the last of the 9 power cube engine mount plate holes:

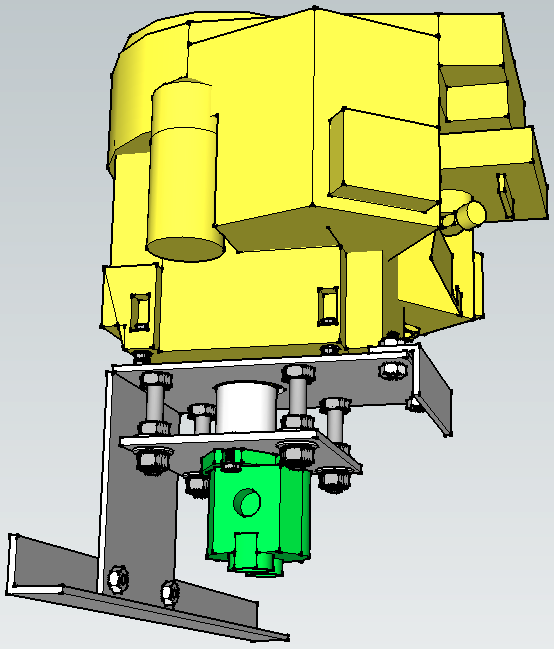

Engine Mounts and Hydraulic Pump Mount

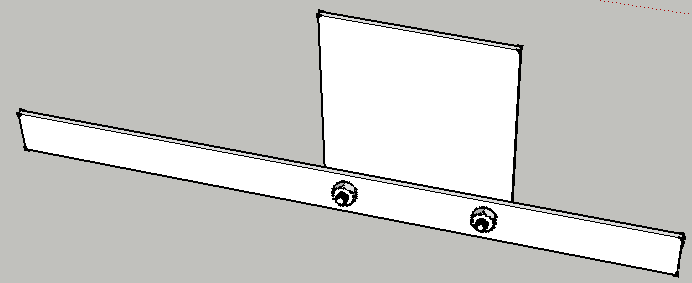

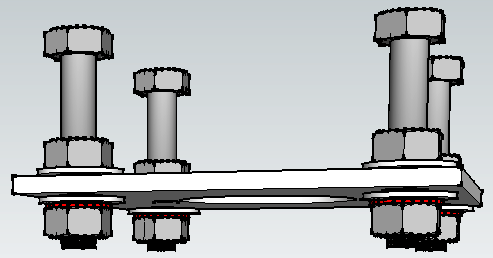

- Bolt the ¼” x 2” x 2” x 8” plate to the ¼” x 2” x 2” x 29” angle as shown using 1/2” x 2” bolts:

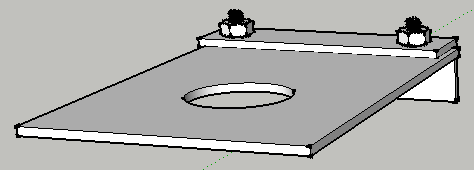

- Bolt the ¼” x 8” x 12” plate to the 8" angle as shown using 1/2” x 2” bolts:

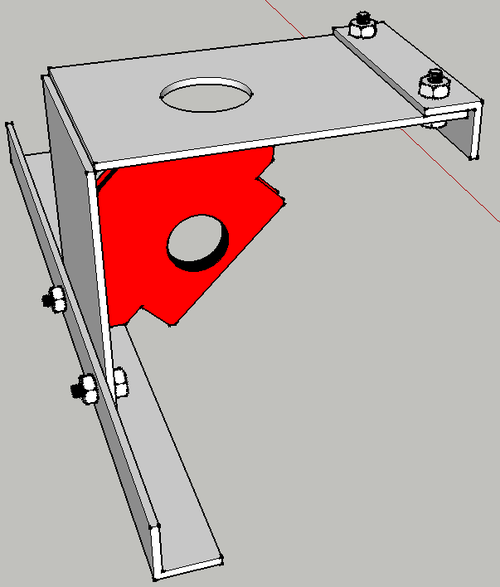

- Align the plate edges and secure at 90 degree angle and weld. We use welding magnets to hold the plates at 90 degrees:

- Mount the engine to the engine plate using [4] 5/16” x 2” bolts. The method for mounting may depend on your engine. See the following video for details:

- Examine the engine shaft – it should be 2” long. If longer, cut the shaft to extend no more than 2” from the case. This length is necessary for the coupling. Put the larger keystock in the engine shaft and slide the shaft coupling on the engine shaft and tighten the allen screws to hold it in place.

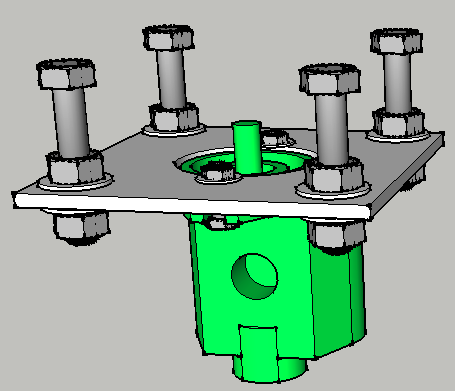

- Assemble the 8” x 8” pump plate as shown with [4] ¾” x 3.5” bolts and [8] 3/4” nuts, [8] washers and [4] lockwashers. Tighten the nuts to hold the plate firmly:

- Mount the pump to the pump plate using [2] 7/16 bolts, nuts, lock washers and flat washers:

- Make sure the key is in the pump shaft and slide the pump shaft into the bottom of the shaft coupling and tighten its allen screws. The bolt heads should just be touching the bottom of the engine plate. Tack and weld the bolt heads to the engine plate.

- Lower the engine/pump assembly into the frame. Adjust it so the engine plate is parallel with the frame and weld the 8” angle iron to the reservoir and the 29” angle iron to the frame.