Rugby approach: development overlaps across several stages of development

Ragarding product development methodology, several timing approaches can be applied for development steps. Extreme Manufacturing relies on maximum overlap of stages and constant learning interplay between the stages.

From Harvard Business Review, Janauary-February 1986 - [1]:

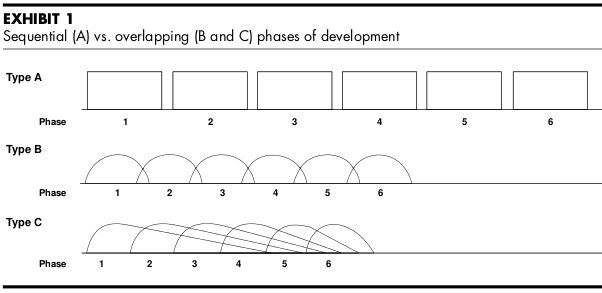

Under the rugby approach, the product develop- ment process emerges from the constant interaction of a hand-picked, multidisciplinary team whose members work together from start to finish. Rather than moving in defined, highly structured stages, the process is born out of the team members’ interplay (see Exhibit 1). A group of engineers, for example, may start to design the product (phase three) before all the results of the feasibility tests (phase two) are in. Or the team may be forced to reconsider a decision as a result of later information. The team does not stop then, but engages in iterative experimentation. This goes on in even the latest phases of the develop- ment process.

Exhibit 1 illustrates the difference between the traditional, linear approach to product development and the rugby approach. The sequential approach (often referred to as the Waterfall method), labeled type A, is typified by the NASA-type PPP system. The overlap approach is represented by type B, where the overlapping occurs only at the border of adjacent phases, and type C, where the overlap ex- tends across several phases. We observed a type B overlap at Fuji-Xerox and a type C overlap at Honda and Canon.

Appication

leading companies show six characteristics in managing their new product development processes:

- Built-in instability

- Self-organizing project teams

- Overlapping development phases

- “Multilearning”

- Subtle control

- Organizational transfer of learning