Steam Engine Build/Flywheel

Jump to navigation

Jump to search

Main > Energy > Steam Engine

Steam Engine Build Instructions

Description

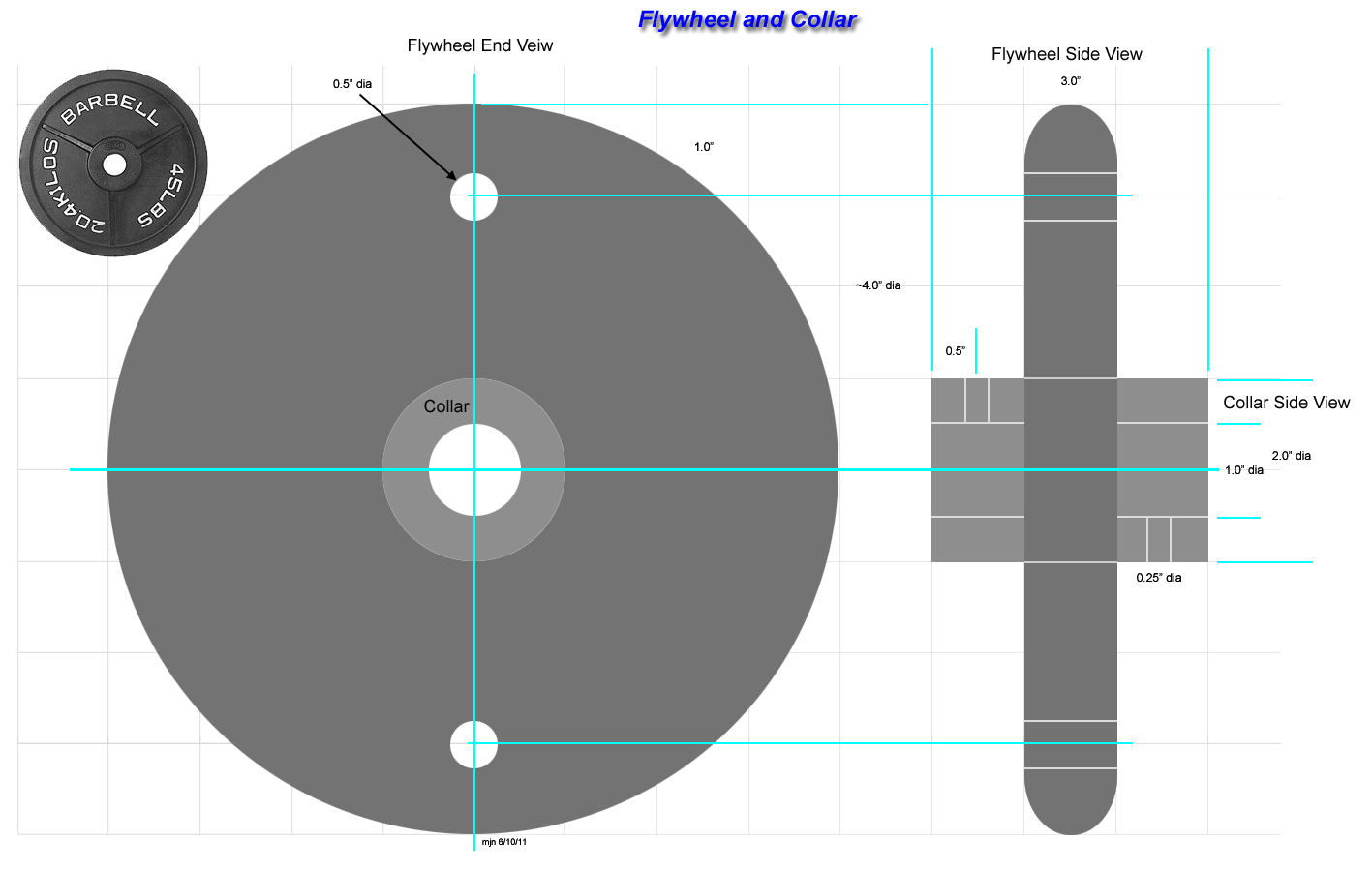

The flywheel is used to add momentum to the motion of the steam engine. This is important in a bump valve design since the flywheel carries the piston during just before top dead center when steam is admitted to the cylinder clearance space. Without the flywheel, the engine is likely to stall.

The flywheel illustrated here has two holes that can be used to insert a hand crank for starting the engine manually. Handle is not shown.

The flywheel has two elements:

- Flywheel weight

- Collar

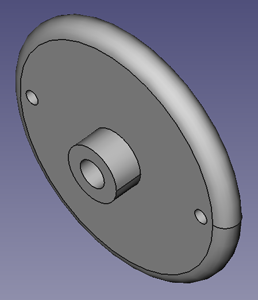

CAD

Drawing

Instructions

Alternating the Flywheel Weight

- Purchase or buy a weight-lifting weight plate of around 45 pounds with a 2.0" shaft hole. Exact weight doesn't matter, though diameter must be smaller than the pillow block support height.

- Optionally drill two holes (for balance) to receive a hand crank.

Making the Collar

- Cut a section of steel pipe with an I.D. of 1.0" and an O.D. of 2.0" to be 3.0" long.

- Drill two, balanced 0.25" set screw holes.

- Tap the holes to receive a 0.25" set screw.

Assembly

- Insert the collar into the weight.

- Weld them together.