Steam Engine Reviews/Arrowhead Bump Valve Summary

Jump to navigation

Jump to search

Main > Energy > Steam Engine

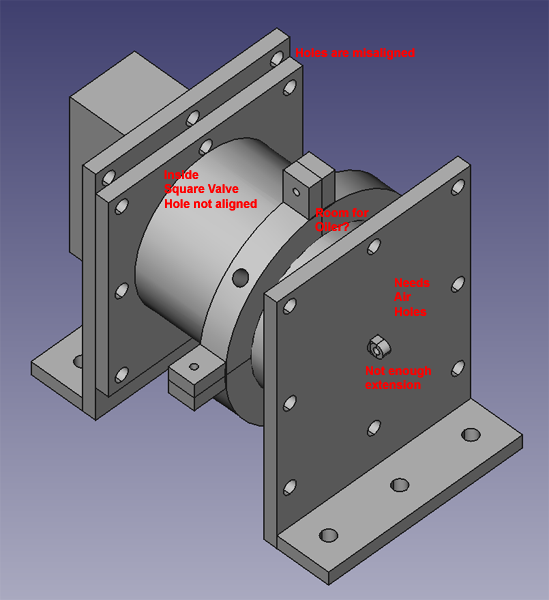

The so-called Arrowhead Bump Valve engine design has been reviewed by several people at the current time (7/20/11). This page summarizes the design problems and provides suggestions on how to deal with them.

Problem Summary

- Horizontal layout promotes wear, jamming, etc.

- Water can condensing in the engine leading to a blow-out.

- Placement of exhaust vent means compressing air in the cylinder and losing work.

- Steam is admitted before top dead center, losing some work.

- Valves must seat and create a seal against steam.

- Valves are heavy and slow to react.

- Valves take a beating from bump pins.

- Valve opening and timing is critical - difficult to adjust.

- Cylinder liner is expensive.

- Cylinder end needs holes to let in (and out) air.

- Piston rings are expensive.

- Oiler is expensive.

- Piston head is heavy, moving it loses work.

- Piston head has no heat shield.

- Bump pins may vibrate out of their holes.

- Oil mixes with steam and causes pollution.

- Crankshaft is built up of parts that must be precisely aligned or vibration results.

- Engine is hot - no shields for safety.

- Crankshaft is open - safety hazard.