Modular Stove Fabrication Procedure

Linked from Stove. Produced by  with adherence to

with adherence to

See build below and installation here:

BOM

Master BOM - only 5 unique stock materials + fasteners. edit

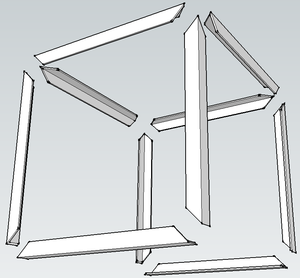

Frame

- [12] - 4' long

- [18] - 2' long

- [6] - 1' long

- Total - 90', $217

Panels

Note: undersize red panels slightly so they fit within 2'x2' or 1'x2' panel areas.

- [1] 1'x2' (front door of ash chamber)

- [3] 2'x2' (front, top, and flue panel)

- [1] 19"x2' (flame deflector)

- [1] 19"x42" (ash tray)

- [2] 3"x42" (ash tray)

- [2] 3"x19" (ash tray)

- Total: one sheet; $100

Mild Steel Prices

- 1/4"x2"x2" angle - $2.41/ft

- 1/8"x1/2"x1/2" angle - $0.66/ft (or 1/8"x3/4"x3/4" angle)

- 1/8"x4'x8' sheet - $100

Build

Fabrication Diagram Master Index

Fabrication Diagram

Annotation: Angle cutting and plasma cutting can occur in parallel. Start with angle holders for welding. As soon as frame members are cut and mitered - begin on frames. 2 people can work on frame. Start with ash tray panels, weld them. Weld door handles. 4 people on welding total - 2 on main and 2 on ash chamber. 1 person marks the metal - 4' sections - which can't be fed with stop. 2' and shorter pieces are fed with stop on ironworker.

Intro to Fabrication Diagram and process:

Step 1

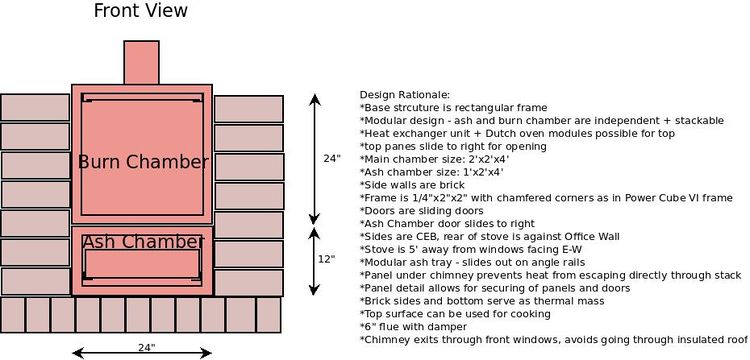

Study Concept: 2 boxes with slideable cover plates clamped down. Ash tray and flame deflector plates side in similar fashion.

Step 2

- Cut angle for 2 mitered frames, just like for Power Cube 6. 1/4"x2"x2" angle BOM:

- Use Ironworker for mitered cuts:

- Result: corners fit together such that all metal angle form flat planes

Angle cutting time lapse:

Quality Control

- 3 corners fit so there is no more than 1/8" space anywhere

- length of members within 1/4" tolerance

Then, the build:

Step 3

- Plasma Cut all panels

- Do not cut out hole in flue panel. Mark Exact location of this hole in situ once the roof hole has been made to make sure the flue is perfectly vertical.

- Includes ash tray and flame deflector panels

Step 4

- Cut panel holders - [10] pices of 1/8"x1/2"x1/2" angle - 2' long

- Data point: with stop in place, ironworker does these in about 10 seconds each. Stop setup: 2 minutes. Pieces held by hand.

Step 5

- Weld frame - all 1/4"x2" angle - as this:

- Mitered corners welded, ground flat

- Rails for flame deflector and ash tray are not mitered

Frame time lapse:

Start with Raw Stove Frame, add Stove Rails, then weld on Stove Grate. This is all 1/4"x2"x2" angle. Completedf fire chamber frame:

- Grate data point: cutting is 20 seconds per piece for angle with stops. Clamp not used for cutting 1/4"x2"2" angle - can be held by hand, but springless clamp would be good.

Ash tray frame:

Step 6

- Weld all panel holder nuts to holders, and holders to frame

- Weld on holding nuts - technique:

- Weld holders to frame. Use a magnetic holder to align the two.

- Mount panels

Step 7

- Weld ash tray

- Weld handles to doors

- Weld 12 grate pieces to frame (23" long angle, 1/4", like rest of frame

Step 8

- Plasma cut flue panel

- Plasma cut flue sections, including damper section

- Plasma cut flue section joints

- Fabricate damper

Step 9

- Lay brick foundation for stove as in Concept Drawing - 4' wide by 5' long, length facing E-W

- A bench can we retrofitted to north side of stove

- Stack ash chamber and burn chamber sections, against rear brick wall in HabLab, stove door facing west, 4 feet from window

- Mount panels and doors

- Insert flame deflector and ash tray

Step 10

- Build up Bricks on 2 sides of Stove

- Install flue

http://instagram.com/p/RBahyvQvon/

Step 11

- Break flue exit out of glazed door side or through roof

Design Rationale for Roof vs Side Window

Fabrication Considerations

- 2 additional angle joints and 2 additional pipe sections compared to flue pipe straight out the top

Performance Considerations:

- Additional 4.5 square feet of heat exchange from 3' longer flue pipe, or 18% increase in heat output

- $215 materials cost + roof insulation + labor

- 20 sf of 1/8" sheet - $60 at $3/sf

- $155 for 20' of flue pipe cf $93 for 12' of flue pipe, 6", 14 gauge, cf $350 for Insulated Chimney Pipe

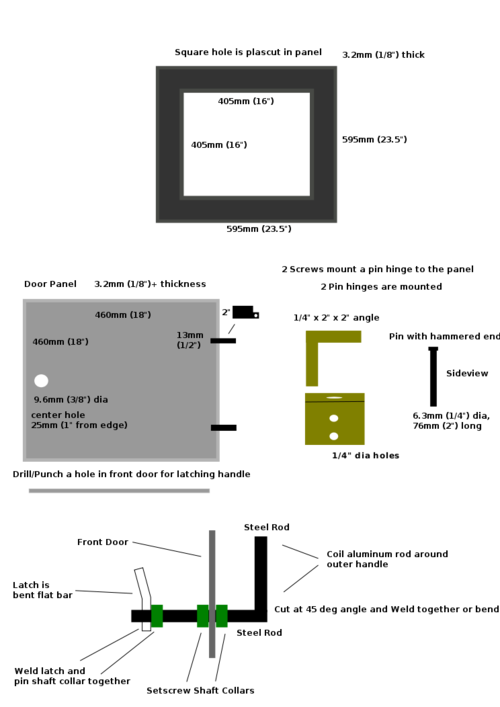

Modify Front Interface

The front sliding door expands non-uniformly when the stove heats up, preventing the door from being moved easily.

A hinged door design is warranted. See Hinge