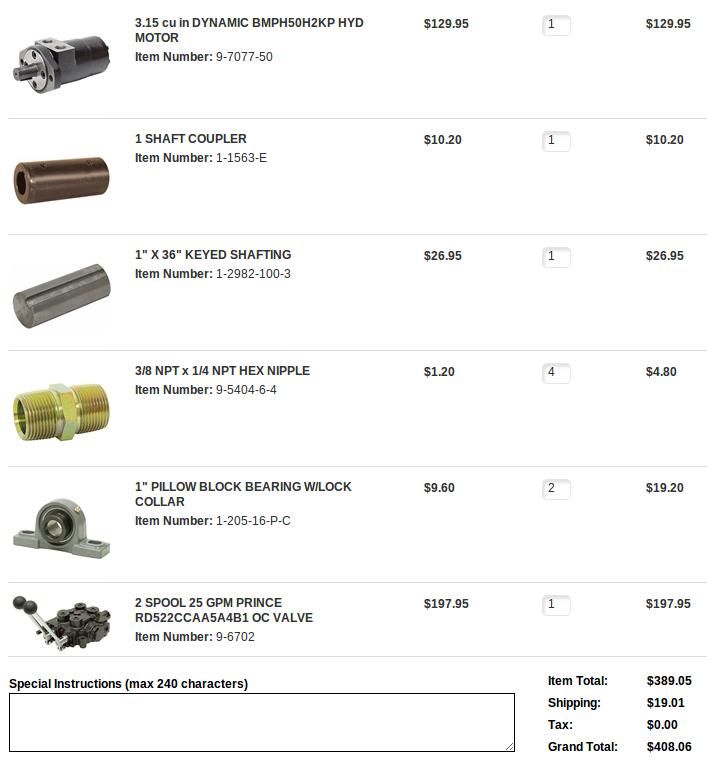

Surplus Center CEB 6 Partial Order

Jump to navigation

Jump to search

- Note- motor is 12 gpm (11.85) continuous, so must be activated in parallel with other element or flow reduced

- Advanced flow reduction strategy - running other components in parallel

- specific speeds and flows must be calibrated

- motor is rated for 1800 psi (1840) so pressure reducer must be used

- for 14 gpm - can use small cylinder motion to reduce flow, or just needle valve.

- for 28 gpm must have 3 solenoids going at once for shaker not to blow up

- cushion valve must be used in all cases

- p spike upon startup is an issue - needs to be tested - data collection - ie - pressure spike upon startup

- to test cushion valve, observe pressure with pressure valve in manual mode

- next steps - use log splitter 2 stage pump for faster pressing

- motor is 3.15 cu in/rev