Talk:CircularKnitic Parametric

Jump to navigation

Jump to search

adapting for variable needle size

ride height of needle

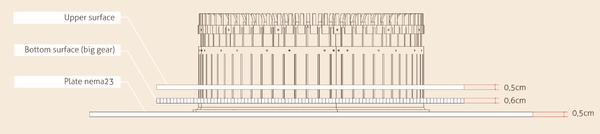

- the geared and non-geared plates sandwhich the butt of the needles to maintain control of the needles height

- before the needle is sent up it is breifly lowered slightly to pull tension on surrounding fabric.

- the lowest point of the groove on part CKp3.scad that the butt of the needle rides should be at this lowered position

- also the the length of the needle below the butt needs to have room to be lowered without hitting the top of the CKp3 base

- in general:

- the sandwich needs to be raised higher if the needle is longer below the butt

- the butt groove needs to be raised as well

- the design could be changed to put holes in the base of CKp3 and the main table plate to allow the bottom of the needle to move freely downward

- the butt groove would could start lower

- could move all of CKp3's mounting screws outside of the circle.

- use a style of claws similar to the inverse of CKp4 to hold up CKp1 from the base

bent tail

- some standard needles feature a design where the area section below the butt is bent up to meet the butt.

- this effectively doubles the "Y" dimension for the "B" dimension

mountain

- wall of CKp3 might need to be made thicker to counter the torsional forces on the needle butt while passing through the mountain

- perhaps CKp3 wall thickness = ((H-Y)/2)