Talk:Cost of CEB Block

Jump to navigation

Jump to search

Commercial

- $1 for unstabilized, $1.20 for stabilized - [1]

OSE Costs

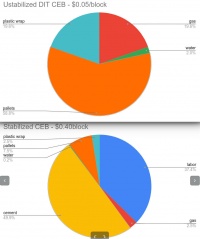

![]() Hint: One scenario missing is soil digging, which adds 1.5 gallon per hour cost of fuel to the overall operation.

Hint: One scenario missing is soil digging, which adds 1.5 gallon per hour cost of fuel to the overall operation.

Another missing scenario is blending of soil before entering hammermill. Usually soil is not at the right sand-clay ratio right out of the ground. If it is, ignore this. If not, the material needs to be blended before entering the hammermill as we have only one soil input which requires pre-blended soil-sand mixture.

- Costs based on availability of on-site soil

- 6 block per minute machine - 8 hour shift - 1 gallon per hour for CEB, 0.5 gallon per hour for tractor (25% duty cycle assuming nearby pile of soil that has already been dug), one gallon per hour for soil mixer, local clay soil, 10% cement stabilized

- 5.5 maximum ideal rate. I decreased my machine rate in order to hold compression longer to improve block.

- Total costs for 2880 block:

- 2.5 gal* 8=20 gal fuel = $50 at current gas prices

- Cement - $10 per bag for 100 block - 29 bags of cement - $290

- 1 94lb bag gives 44 block at 10%

- 94=0.1(BatchMass). BatchMass=940lb. 940lb / 21 lb per block = 44 block

- Labor - $25/hr for tractor operator, $15/hr for stacking block on pallets x2 - $440/day

- Water - 20 ml/block = 58 liters = 15 gallons at 2 cents - 30 cents in water

- Plastic wrap

- Tarps to cover plastic wrapped blocks to keep sun away OR overhead of covered structure to store wrapped pallets

- Pallets

Total costs -