Torch Table Design Evolution 2.24.09

Main > Digital Fabrication > RepLab Tools > Torch Table

Introduction

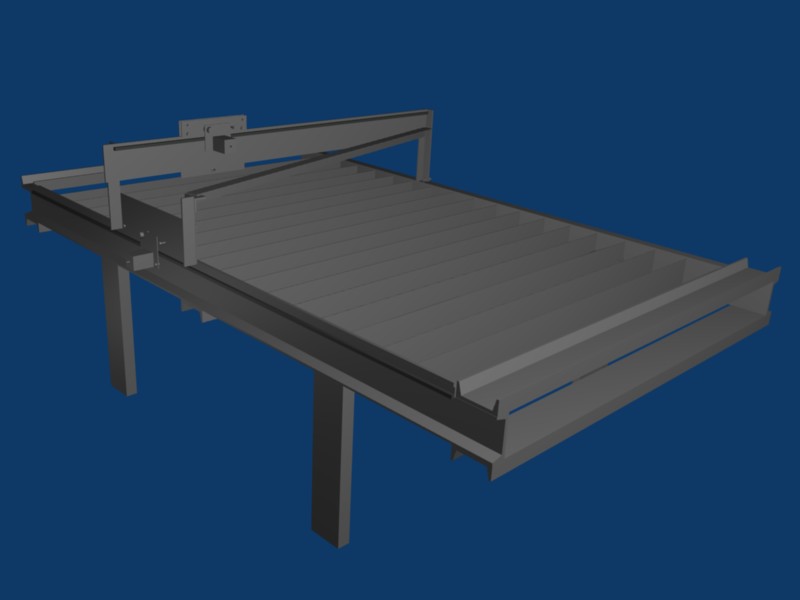

Here is a simplified design, with spring-loaded motor meshing on rack. Spring not shown. Design follows MechMate. MechMate is much more complicated than it needs to be - and requires laser/plasma cutter for fine parts. As such, it's not the simplest, most replicable, cheapest design as called for in OSE Specifications. For purposes of the Open Source Fab Lab, it should be simplified to use as many stock steel sections, without sacrificing performance.

We have a simple design for a torch table (low torque requirement compared to Router Table), which can be upgraded to 2-sided drive for Router Table applications.

Design Rationale

- Lightest possible gantry - 25 lbs

- Gear rack inverted, so have no dirt get in it

- Rolling surfaces inverted if possible, to eliminate dirt

- Least number of parts

Images

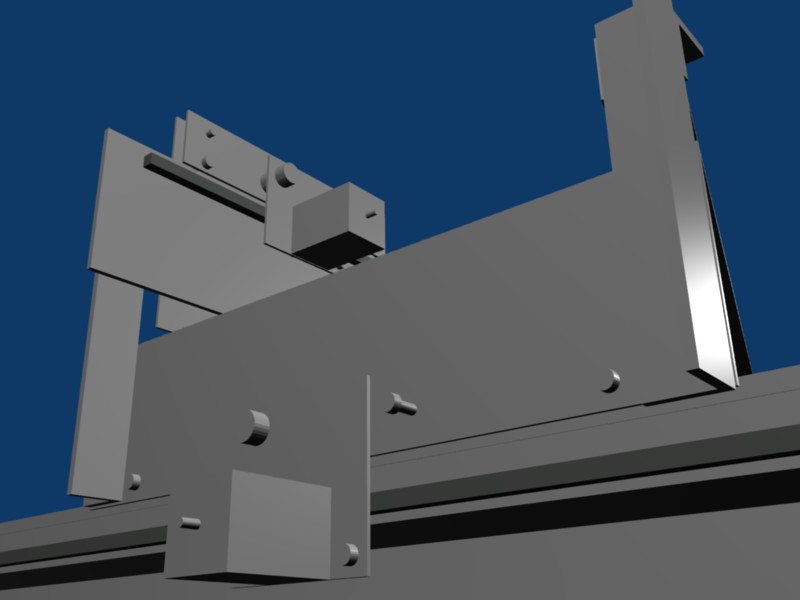

X Axis Detail

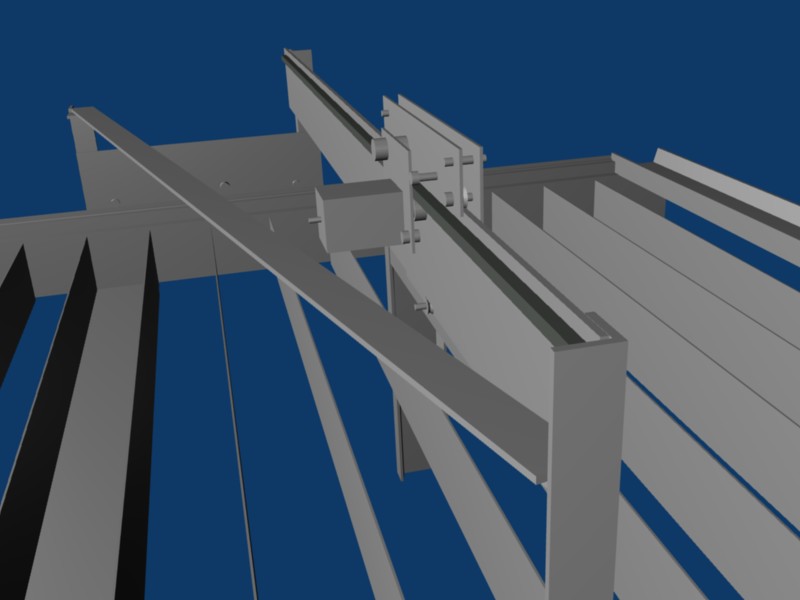

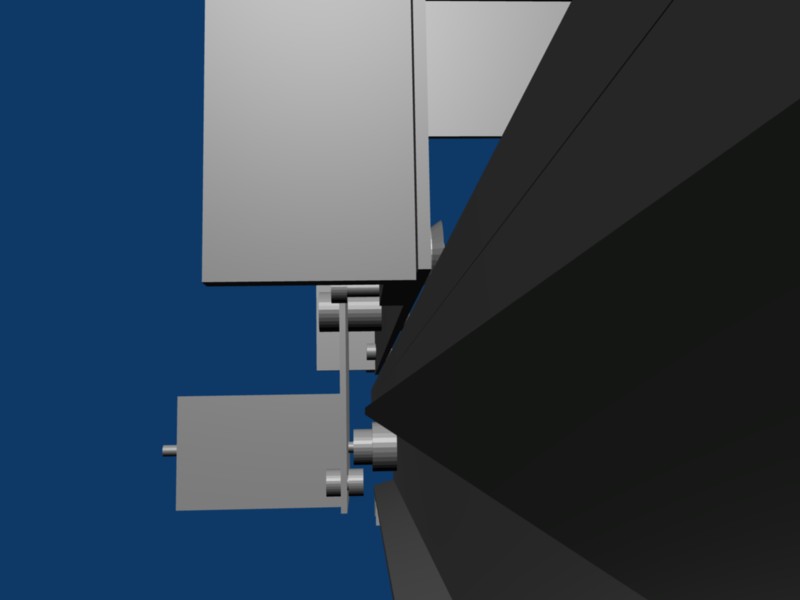

Note a 1 1/4 inch square cold-rolled rail, to which a gear rack is attached. A small angle holds the roller cam on top of the cold-rolled rail.

Gear rack is attached to cold rolled rail. Spring tensioning of stepper motor plate is used. Stepper motor plate is attached to the gantry through a bearing to allow rotation, for spring tensioning

.