Torching Tutorial

Commercial Introduction

Factor e Farm Torching 101

Comments

From Mike Hill:

The test for hardness is "Rockwell", which is a machine with a hard tip that dimples the steel.

The amount the steel hardens is a function of the amount of carbon in the metal. The more carbon the harder it will get. Tool steels have other metals added, but that's not important for the basics. If steel is heated until it's not magnetic and then quenched it will harden. It's best to just heat the steel to the point of not being magnetic and then quenching. If you heat past that you just increase the chances of cracking. Different metals are quenched in different liquids. Typically, when a metal has a higher carbon content the quench liquid is a more viscous liquid like oil to slow the quench down and prevent cracking. After metal is quenched it must quickly be tempered to prevent brittleness and cracking. This can be done in a regular cook oven at around 400 degrees. You can also file a clean spot on the metal and then heat the metal slowly with a torch until it's a light straw color. If you go past that you have to heat it and quench again. Different steels require a different tempering heat. If a piece of steel becomes hard and you want it soft for drilling or machining you can anneal it by heating it until it's not magnetic, then putting it in ashes or vermiculite for a slow cool. This will soften the metal. An easy way to test a steels hardness is to skim across it with a file. If it skates off the metal the metal is hard, if it digs in it's not. A low carbon steel can be hardened significantly with "Super Quench" which is water with added surfactants to make it "wetter". Low carbon steels can also be case hardened with products like Casenite or Cherry Red. That's the basics.

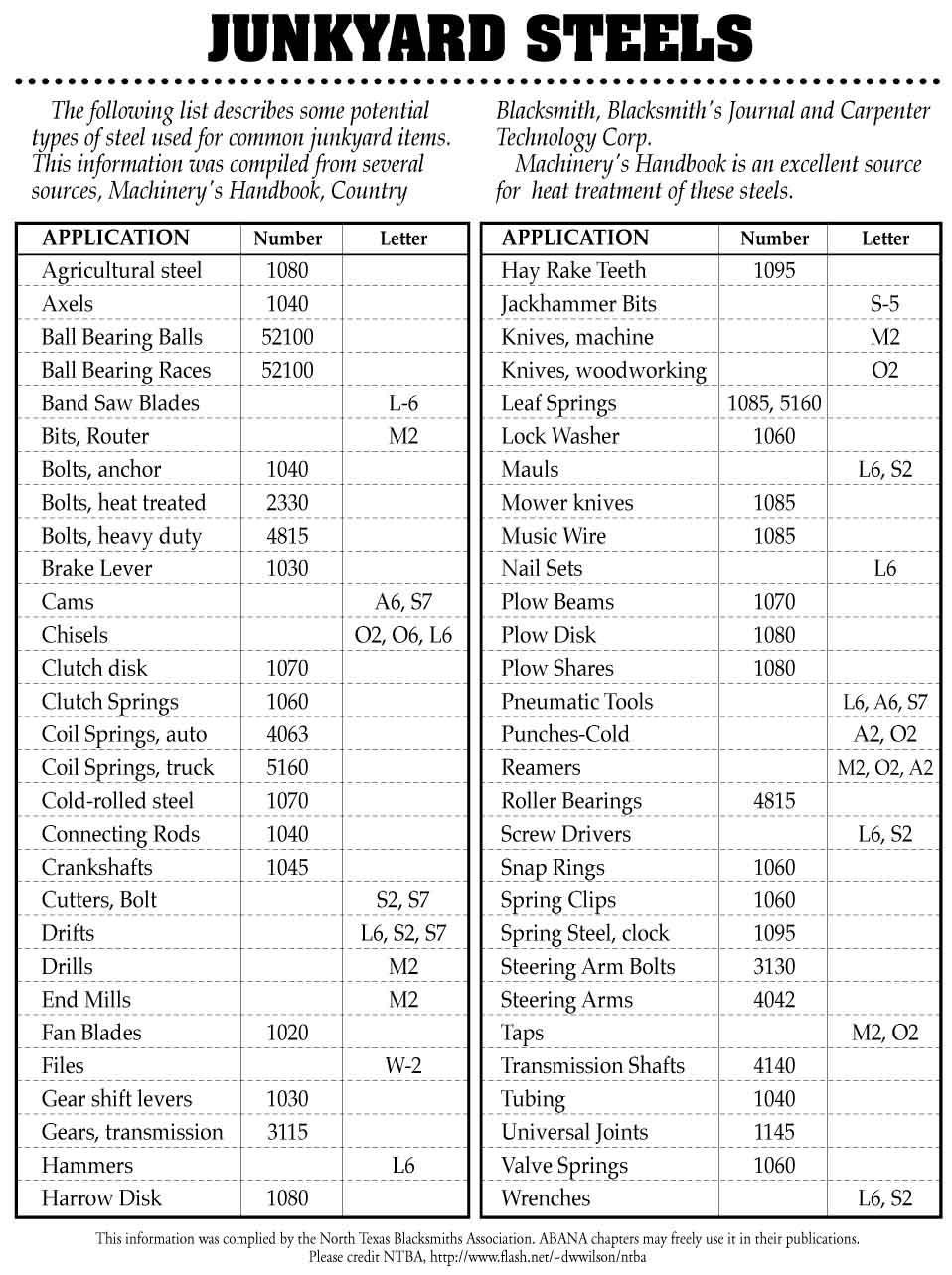

I've attached a chart of some common junkyard tool steels. It's a great way to get tool steel on the cheap.