Ultrasound Torch Height Controller

http://www.cnccontrols.com/thcontrol.asp

with a $32 open source part:

https://www.adafruit.com/products/984

it looks like the ez4 might have a better beam geometry for this purpose.

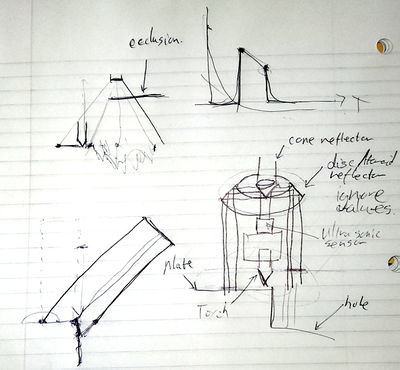

a problem that exists with using any beam is what to do if you have a hole. you could use multiple sensors and take the minimum to deal with this situation. or you could point the beam up in the oposit direction and use a conical reflector, that directs the beam toward another disc. This gives you get a read of a circular pattern around the whole torch. The software can eliminate any values less than some tolerance to deal with the reflectors, and from there take the minimums as the measured height. any of the problems with holes would be eliminated with this method.

See bottom right image for the double reflector to read a disc around the torch head. although a little more required in the build stage, the geometry simplifies a lot of the issues that could arise from software, filtering errors, and the problem of what to do when you encounter a hole.

See also Sensing_Distance_from_Work_Piece