CNC Sawmill

Jump to navigation

Jump to search

Concept

- Integrate Marlin/RAMPS/Touchscreen since we already use it - with larger stepper motors as chain axis drive for the sawmill - [1]

Sure, but use a more dedicated GRBL/RAMPS with touchscreen. [2]. Can be productized.

Sure, but use a more dedicated GRBL/RAMPS with touchscreen. [2]. Can be productized.- But - second route still requires a custom touchscreen with its own MCU, not the standard screens from Marlin - so the Degeneracy criterion fails.

thus, just modify Marlin, and while not designed for industrial cnc, if we reprogram Marlin, we make it as effective as GRBL/LinuxCNC if we pay attention to programming in added functionality. [3]. The open source revolution is nigh.

thus, just modify Marlin, and while not designed for industrial cnc, if we reprogram Marlin, we make it as effective as GRBL/LinuxCNC if we pay attention to programming in added functionality. [3]. The open source revolution is nigh.

- For future proof industrial grade, go to 32 bit controller like Due, which is not more expensive [4]

Working Doc

Part Library

Part Library

Visual History:

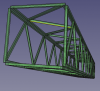

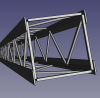

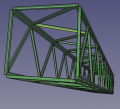

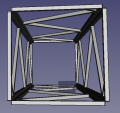

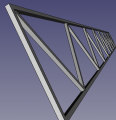

12 foot truss, 4-sided. - FreeCAD -File:12footrebaruss.fcstd

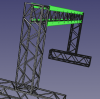

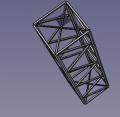

3 foot truss. - FreeCAD -File:3foottruss.FCStd

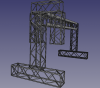

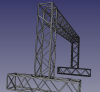

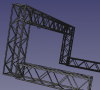

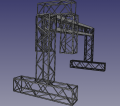

CNC Saw Assembly. - FreeCAD -File:Cncsawassy.FCStd

Small truss. - FreeCAD -File:Smalltruss.FCStd

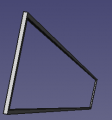

This has the underlying truss sketch. - FreeCAD -File:Cncsaw.FCStd

Sawmill truss. - FreeCAD -File:Cncsawtruss.FCStd

Options

- Use a 16" circular saw with 2" universal axis. Advantage: turnkey saw. Dis: small cuts only up to 4 or 6", slow (power only 3 hp)

- Use long space frame axis for stability, mount on trailer or SMV

- Use mobile stiff frame on wheels

Industry Standards

- China wares - [5]

- Lucas Sawmill - [6] - setup time with wires for stability is a disadvantage. Solid space frame for moving the OSE mill into the field would help. Peterson [7] setup time is no better. But, it can be set up in the field on rough terrain.

Decisions

- Portable or stationary

- Rough terrain or not

- CNC or manual

- Easy to set up (solid frames) vs not (multi-piece frames with need to align)

- Hand portable vs heavy, requiring other machines to move it

- Production (32 hp - 100 hp) vs hobby (7 hp - 27 hp)