Stock Pivot Plate: Difference between revisions

(→Note) |

(→Note) |

||

| Line 17: | Line 17: | ||

<span style="color:red">''''Needs the Stock Pivot Plate Sketchup with 3" hole, not 4.75" hole. Further, 6 in 60 Buildout testing has shown that the stock pivot plates need to be 1/4" shorter at the rounded part because of conflicts when 2 of these plates are put together. To address this, please generate a stock plate where the half circle begins 1/4" further away from the rounded edge, so that the overall plate is not 16" long, but 15-3/4" long. Leave the curvature identical, just move it 1/4" inch away from edge.</span> | <span style="color:red">''''Needs the Stock Pivot Plate Sketchup with 3" hole, not 4.75" hole. Further, 6 in 60 Buildout testing has shown that the stock pivot plates need to be 1/4" shorter at the rounded part because of conflicts when 2 of these plates are put together. To address this, please generate a stock plate where the half circle begins 1/4" further away from the rounded edge, so that the overall plate is not 16" long, but 15-3/4" long. Leave the curvature identical, just move it 1/4" inch away from edge.</span> | ||

Placeholder for 1/4" shorter pivot plate with 3" hole - SKP: [[File:pivplate1575.skp]] | Placeholder for 1/4" shorter pivot plate with 3" hole - SKP: [[File:pivplate1575-3.skp]] | ||

Placeholder for 1/4" shorter pivot plate with 3" hole - DXF: | Placeholder for 1/4" shorter pivot plate with 3" hole - DXF: [[File:pivplate1575-3.dxf]] | ||

Placeholder for 1/4" shorter pivot plate with 4.875" hole (best for welding) - SKP: | Placeholder for 1/4" shorter pivot plate with 4.875" hole (best for welding) - SKP: [[File:pivplate1575-48.skp]] | ||

Placeholder for 1/4" shorter pivot plate with 4.875" hole (best for welding) - DXF: | Placeholder for 1/4" shorter pivot plate with 4.875" hole (best for welding) - DXF: [[File:pivplate1575-48.skp]] | ||

=Notes= | =Notes= | ||

Revision as of 17:59, 4 July 2013

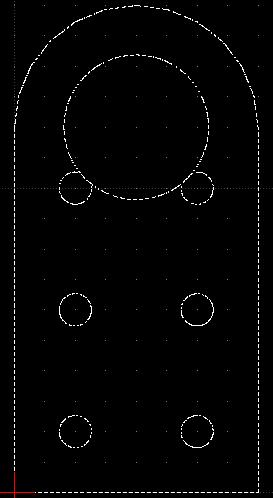

DXF file - File:Stockpivot.dxf

Note: the correct large hole diameter in the above is 4.75", which gives 1/8" room around the DOM for effective welding.

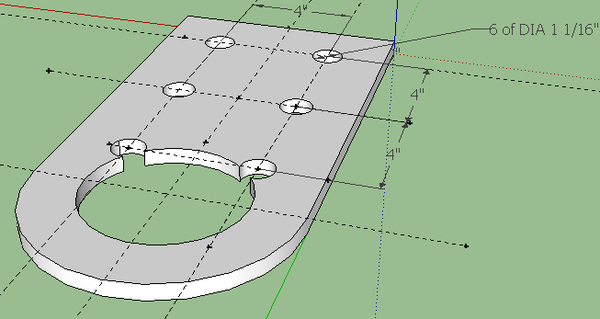

Note: the above is used to generate a CAM file for CNC Torch Table cutting and Laser Cutter modeling - for the pivot plate. In practice, a 4.5" OD DOM with 3" ID is welded inside the 4.75"-4.875" hole (Mickey Mouse hole) to generate a pivot plate for a 3" shaft. To generate a CAM file for 3D printing, one must consider the 3" tubing and print out a 3" hole, not a 4.75"-4.875" hole. 4.75" is recommended as a hole for CNC cutting (leaves exactly 1/8" space around DOM for welding) - and a 4.875" hole is recommended for manual cutting to address inaccuracies.

- File:Stock Pivot Plate.skp

- File:Stock Bonding Plate 8 inches x 16 inches.skp

- File:Stock Spacer Plate 8 inches x 8 inches.skp

Note

'Needs the Stock Pivot Plate Sketchup with 3" hole, not 4.75" hole. Further, 6 in 60 Buildout testing has shown that the stock pivot plates need to be 1/4" shorter at the rounded part because of conflicts when 2 of these plates are put together. To address this, please generate a stock plate where the half circle begins 1/4" further away from the rounded edge, so that the overall plate is not 16" long, but 15-3/4" long. Leave the curvature identical, just move it 1/4" inch away from edge.

Placeholder for 1/4" shorter pivot plate with 3" hole - SKP: File:Pivplate1575-3.skp

Placeholder for 1/4" shorter pivot plate with 3" hole - DXF: File:Pivplate1575-3.dxf

Placeholder for 1/4" shorter pivot plate with 4.875" hole (best for welding) - SKP: File:Pivplate1575-48.skp

Placeholder for 1/4" shorter pivot plate with 4.875" hole (best for welding) - DXF: File:Pivplate1575-48.skp

Notes

This is an official file release with dimensions. Current as of May 17, 2013. Newer versions will be uploaded here.

We can then print these out according to the Ultimaker Post on Using Sketchup for 3D Printing.