Samthetechie log

Want a work log too? See Work Log for howto.

copy-pasta stickie begins

day month ??, 2016

Input

Output

Friday Feb 19, 2016

Input

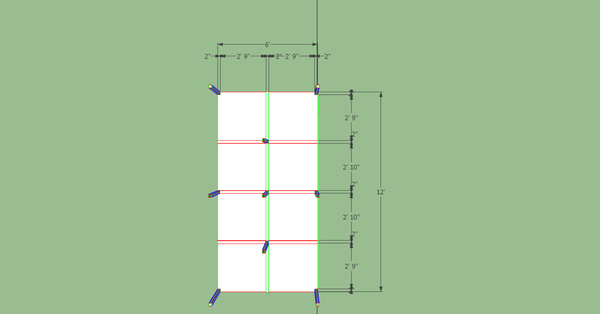

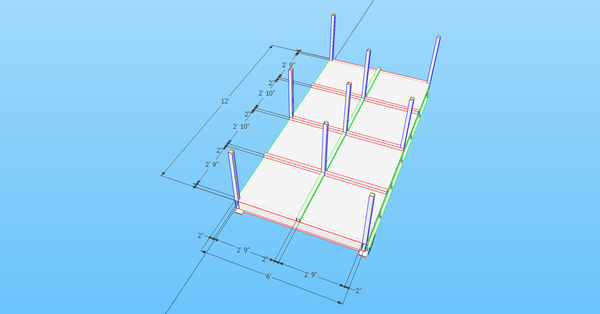

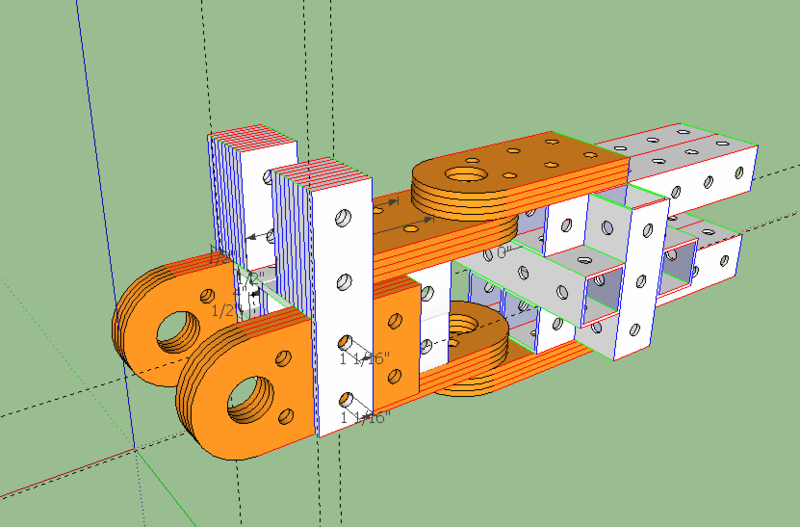

- http://opensourceecology.org/wiki/Warehouse (for a personal project- making furniture vis. Gridbeam).

- Info Box Specification from Marcin: https://docs.google.com/presentation/d/1D1NvEqSOHYbUhPmowhLmFibrSPy3FqolA92r8iD_Jwo/edit#slide=id.p

Output

http://opensourceecology.org/wiki/Warehouse

copy-pasta stickie ends

Friday Jan 29, 2016

Input

- Request from Marcin: "infobox templates for the wiki. We need to use this for every module."

- I googled / looked for some sample code. Found this: https://en.wikipedia.org/wiki/Template:Infobox_CPU

- Waiting for requirements / specification from Marcin

Output

Thursday Dec 19, 2013

Input

- Need to go to Radioshack in Cameron first thing tomorrow to get a Solder Sucker!

Output

Wednesday Dec 18, 2013

Input

Output

Tuesday Dec 17, 2013

Input

Output

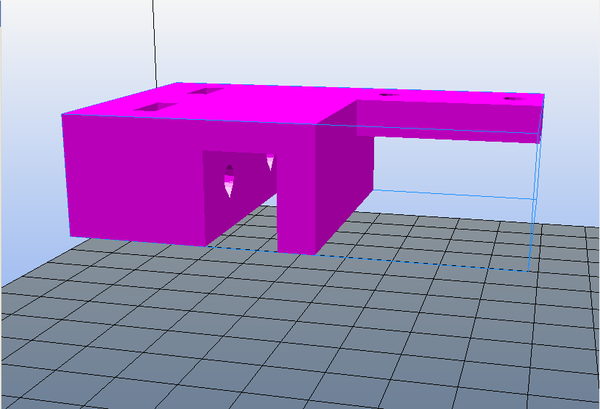

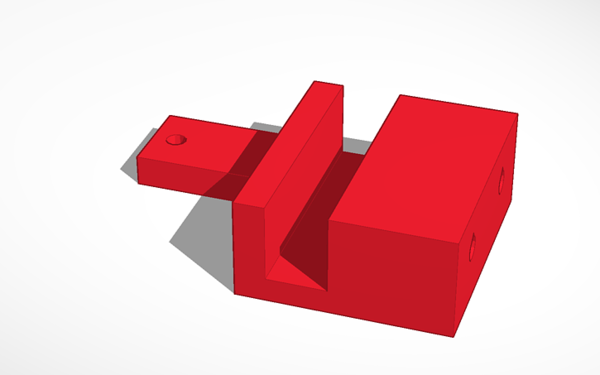

- Designed, printed and test-fitted 3 endstop mounts for the torch table: File:Ose-cnc-torch-table-endstop-y-min.stl, but more endstops are needed!

- Editable online here: https://tinkercad.com/things/bkp94Us6KGH-ose-cnc-torch-table-endstop-y-min

- This endstop mount slots onto and then clamps against the 10mm precision rails on which the CNC Torch Table Axes move.

- Two #8-32 'captive nuts', need to be fitted into the slots and pushed downwards until their threaded centres align with the teardrop-shaped bolt holes

- Here is an example of a captive nut:

Monday Dec 16, 2013

- Working/reliable actuator/motor/output from Python code on Pi, time to focus on the height sensor/input

Input

- GPIO setup and config for I2C on Raspberry Pi: http://learn.adafruit.com/adafruits-raspberry-pi-lesson-4-gpio-setup/configuring-i2c

- Instructables Pi + I2C: http://www.instructables.com/id/Raspberry-Pi-I2C-Python/step4/Install-Necessary-Packages/

- Python Finite State Machines: http://ocw.mit.edu/courses/electrical-engineering-and-computer-science/6-01sc-introduction-to-electrical-engineering-and-computer-science-i-spring-2011/unit-2-signals-and-systems/signals-and-systems/MIT6_01SCS11_chap04.pdf

- Datasheet for AD7747: http://pdf1.alldatasheet.com/datasheet-pdf/view/162320/AD/AD7747.html

- Content from Paul_Log

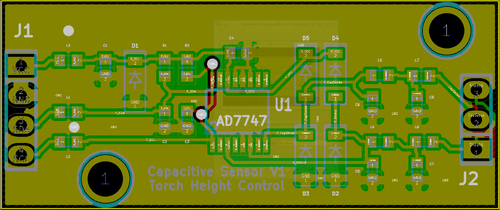

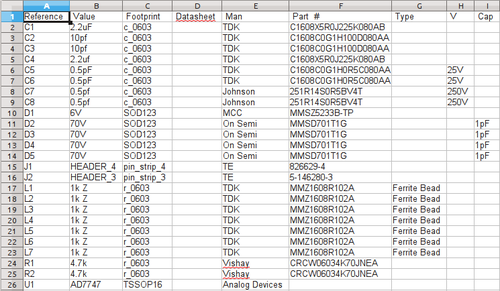

Capacitive Height Sensor

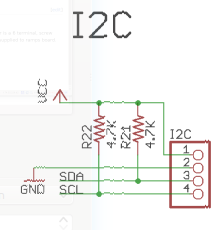

The Ramps 1.4 board contains an unused I2C connector with pullup resistors. This will interface nicely with the AD7747 capacitive sense chip which also has an I2C interface. Pinout for the I2C connector on the Ramps 1.4 board is: .

.

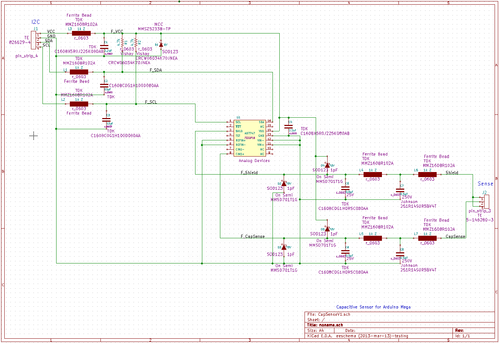

The capacitive sensor board will need to be mounted on or near the torch with the capacitive sensor pickup ring surrounding the torch tip. A long 4 conductor flat flex cable extends from the I2C connector J1 on the capacitive sensor board to the I2C connector on the Ramps 1.4 board. A short (~6 in.) low capacitance shielded cable (RG6U Cable) extends from the capacitive sense input to the sensor ring. The shield of this cable connects to the Shield terminal of J2 pin 1 or 3, the inner conductor connects to the CapSense terminal of J2 pin 2. This board has been designed to withstand considerable noise. For plasma cutting additional ferrite will have to be added to the cables and to the entrance and exit of the metal board housing. Board dimensions 0.7" x 1.675". Mounting 2 times 4-40 nylon screws. PCB price estimate from AP Circuits $37 for 3 boards, $21 for 1 board (31 July 2013).

Capacitive Sensor board Schematic: Top Copper Board Layer:

Top Copper Board Layer: Bom:

Bom:

- Gerber Package:File:CapSenseV1Gbr.zip

- Kicad SCH:File:CapSenseV1.sch

- Kicad PCB:File:CapSenseV1.kicad pcb

- Kicad Parts:File:CapSenseV1Parts.zip

- BOM:File:CapSenseV1.csv

- CSV:File:CapSenseV1.csv

Output

- Did all tutorials and learnt how to use https://tinkercad.com/ to rapidly make printable 3d models and upload to thingiverse.

- Designed, shared and printed a new toilet roll holder for the Hablab!!!

- Designed, shared and printed a 3D printer tool holder tray for the Lulzbot in the Hablab

Sunday Dec 15, 2013

Input

Output

- Soldered up 3 Opto Endstop Kits: http://reprapsource.com/oe-r1

- Calibrated TAZ

- Printed parts on Lulzbot, TAZ and Hydrafabber.

- Setup Octoprint on Raspberry Pi.

- Evaluated Octoprint and conluded that whilst cool it is not sophisticated enough to manage the whole workflow and therefore does not save operator time or reduce complexity

- Better results can be achieved by running Repetier Host on hal9000 and controlling the printers from there.

- Optimised Repetier Host's Slic3r config using Lulzbot TAZ User Manual.

- Setup Repetier Host on hal9000 and printed a doorstop on TAZ

- Tried to print a doorstop on Hydrafabber, extrusion was ok but needs light mechanical calibration / checking.

- Attempted Repair of Ultimaker. Partial rebuild of bowden extruder and adjusted the filament tensioner. Still appears to have a nozzle blockage or other problem at the other end (i.e. the hot end)! Further Repair / Maintenance Required.

- Results at the end of the day: 3/4 of our printers extrude (Lulzbot, TAZ, Hydrafabber), 2/4 are printing well (Lulzbot, TAZ), 1/4 is printing very well (Lulzbot).

Saturday Dec 14, 2013

Input

- Hanging out in Hammerspace

- Advice on woodstove in Hablab due to Pyrolysis which means that wood near the stove or the flue may become pyrolised to the point where spontaneous combustion can occur far below the normal 'flash point' for wood.

Specs are available via NFPA 211. Stove clearances, flue pipe design and height, insulating boards underneath and against the wall. We should, ideally put a spacer in with

- http://woodheatstoves.com/free/NFPA211_old.pdf page 28 (of 59) highlights required clearance distance to combustible materials.

- http://woodheatstoves.com/free/NFPA211_old.pdf page 15 (of 59) read general requirements,

- 10-2 rule which means 10 foot to top of the flue and 2 feet above the top of the roof

- Also check the specifications for gas burning appliances.

- Note: http://www.ehow.com/list_7179572_dangers-burning-osage-wood-fireplace_.html burns very hot! Beware! Must mix with other woods.

Output

Friday Dec 13, 2013

Input

Output

Thursday Dec 12, 2013

Input

- Read OSE_Social_Experiment

- Read GardenBot

Output

- Testing Stepper Motor from the CNC_Torch_Table_2 using a Raspberry Pi

File:Wiring and pinouts for table stepper motor testing (rasp pi).odt

A table showing how to connect:

- NEMA 23 Stepper Motor (Model 57BYGH317)

- Stepper Motor Controller

- via a Ribbon Cable to a

- Raspberry Pi (Model B, Revision 2.0). Pinout: File:Rasp v3.pdf

- Made some edits to GardenBot and tested workflow for rapid creation of Visual BOMs (in prep for heavy Torch Table CNC Documentation)

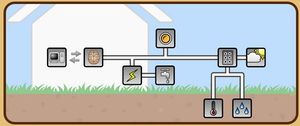

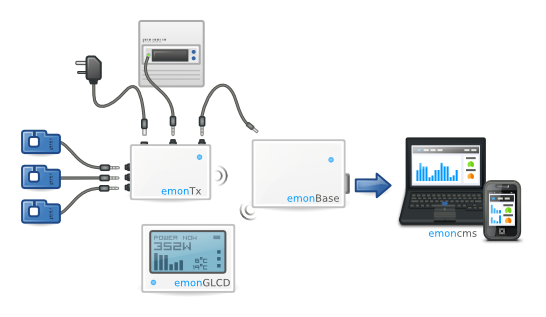

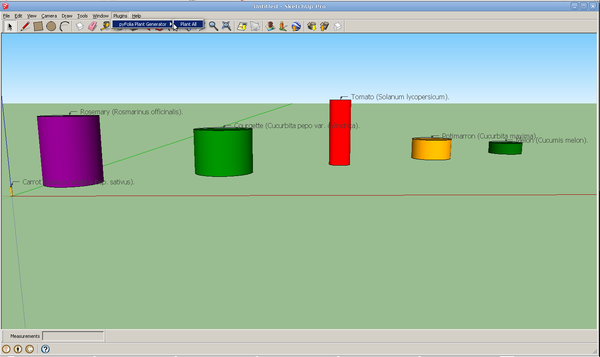

- Thinking about mashup between GardenBot + http://samthetechie.blogspot.com/2013/06/optimised-companion-planting-3d.html + http://openenergymonitor.org/emon/

Wednesday Dec 4, 2013

- Organised a hangout for this weekend to get community help / engagement to ramp up development: https://plus.google.com/events/c3c671969g90itrqvtbhmr2112o

- Made some wiki improvements

Tuesday Dec 3, 2013

- Looked at the new controller electronics that arrived in the post from Lasersaur

- Looked at the current wiring / config of the torch table.

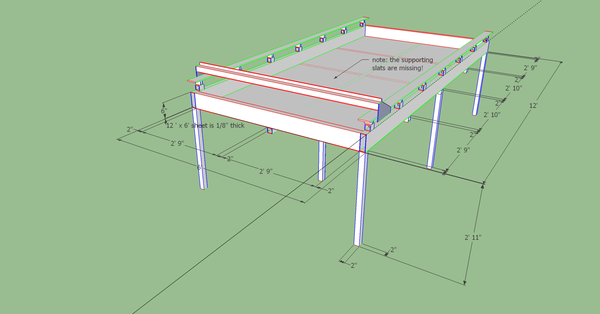

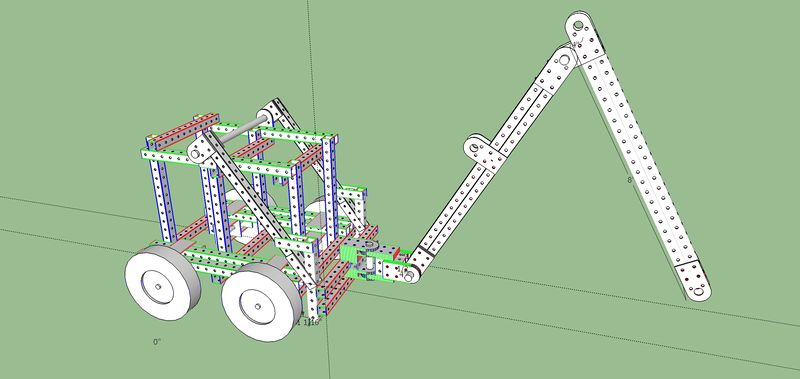

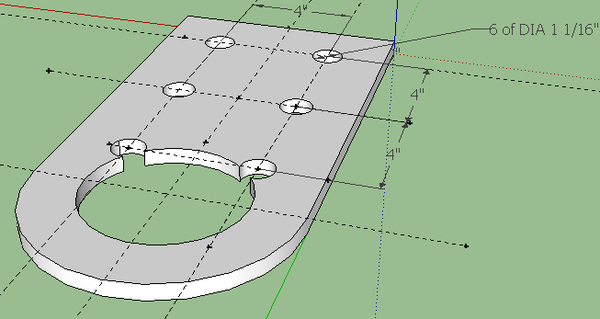

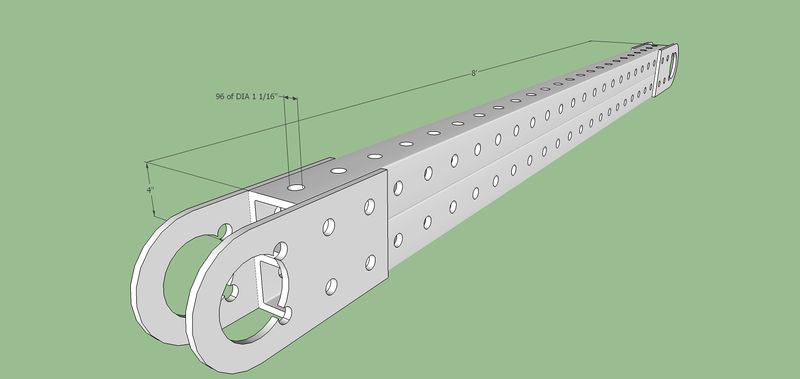

- Made some fresh mesurements on the table and cleaned up my initial Sketchup/CAD models, first version ready for publishing to wiki (note still quite crude, lacks z axis detail): File:CNCTorchTable.skp

Monday Dec 2, 2013

- Emailed Dave from https://solar1.net/drupal/plasma_cnc to see if project still active (found link in: CNC Torch Table - Analysis of Industry Standards)

Sunday Dec 1, 2013

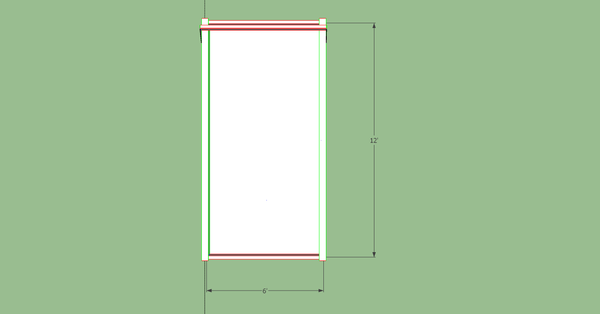

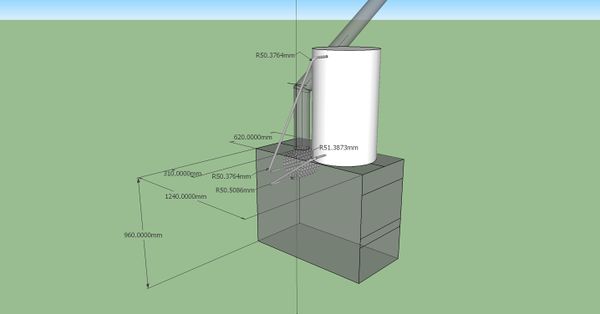

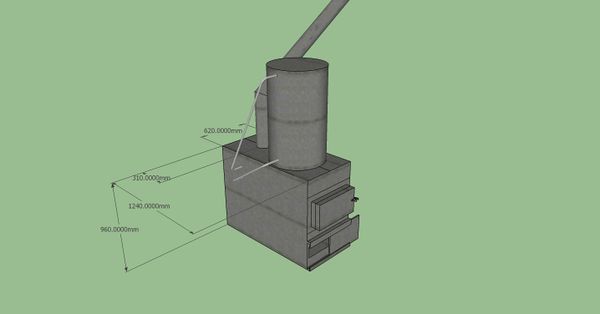

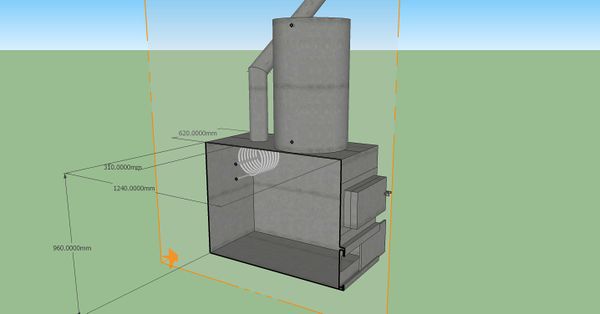

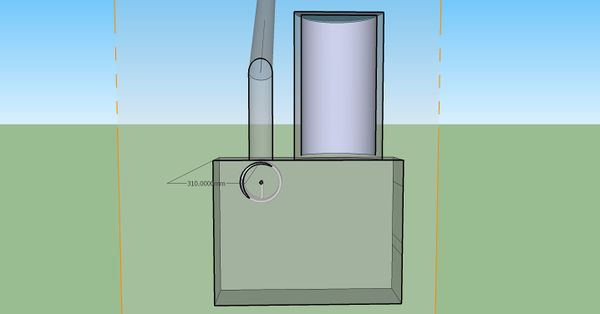

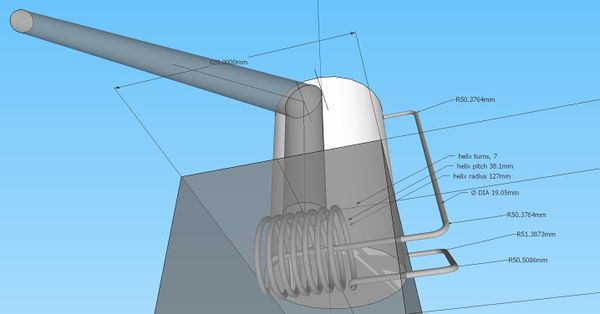

- After a call with Ken Boak (https://twitter.com/Monsonite and http://sustburbia.blogspot.com/) I made a sketchup model of a concept for a 200 litre hot water drum / module for the wood stove in the Hablab.

- Must be able to fail open atmosphere i.e. no valve to vent to atmosphere (pop off valve)

- attach the coil/mounting to a bolt-on plate to aid maintenance of the coils.

- Idea: multiple taps for multiple water temperatures

Saturday Nov 30, 2013

- Printed and installed in the Hablab: http://www.thingiverse.com/thing:143653

- Printed and mounted for use in the electronics area in the Hablab: http://www.thingiverse.com/thing:101991

Friday Nov ??, 2013

Community Video Review

- Looking at videos on (youtube et al.) in order to review plasmacutting theory, tips + techniques

- Made notes on cutting styles and considerations when using plasmacutting technology, best practises, common maintenance tasks etc.

Thursday Nov 28, 2013

* Amazon Wishlist for Electronics Workshop / Video ConferenceiHackerspace Setup: http://www.amazon.com/gp/wishlist/2L7MDQ14CC506/ref=cm_wl_cp_al_wlown

There are items in here for settings up an electronics workbench, core dev of the torch table and setting up the 3d printers other items (like an apple keyboard for the mac mini- note: will use the current keyboard/mouse on the mac mini for the lasersaur dev board): http://www.amazon.com/gp/registry/wishlist/2L7MDQ14CC506/

Note: all items have been compared with reviews and I have gone for the best cost/functionality but also with a very slight lean towards "buy once" on some occasions.

Item breakdown by project, totals ~ $1000

- Electronic Workbench Setup

- PanaVise Model 201 "Junior" Miniature Vise

- TRENDnet USB to RS-232 Serial Converter TU-S9 (White)

- Rigol DS1052E 50MHz Digital Oscilloscope Offered by Technopark.

- Aoyue 968A+ SMD Digital Hot Air Rework Station

- Anytime Tools 127 pc Heat Shrink Wire Wrap Cable Sleeve Tubing Sets Assorted Size e/Case Offered by Anytime Tools.

- SE MZ101B Helping Hands with Magnifying Glass

- Amico 13cm Length Black Anti-static Straight Curved Tweezers 2 Pcs

- ESDProduct Rubber Mat Kit with Wrist Strap and 15' Ground Cord, 1/16" Thick, 3' Length, 2' Width

- Pittsburgh 6" Digital Caliper with Metric and SAE Fractional Readings

- CBConcept Brand Halogen Light Bulb JC 12V 50W G6.35 - Frosted - 10 Bulbs

- Professional Jeweler's Lighted Magnifier Visor - 5 Lenses 1.0X to 3.5X

- AmazonBasics AAA Alkaline Batteries (Pack of 20)

- CnC Torch Table Development

- EasyAcc® 12000mAh Power Bank 4 USB 3.5A Output

- EasyAcc US 5V 2A Universal Travel AC Micro USB Wall Charger

- TP-LINK TL-WR702N Wireless N150 Travel Router,Nano Size

- Edimax EW-7811Un 150 Mbps Wireless 11n Nano Size USB Adapter

- Video Conferencing Setup

- Logitech HD Portable 1080p Webcam C615 with Autofocus

- MXL AC404 USB Conference Microphone Offered by Amazon.com.

- USB 2.0 A-Male to A-Female Extension Cable (9.8 Feet/3.0 Meters) Offered by Amazon.com.

- Apple Wireless Keyboard MC184LL/B

- 3d printer server Setup

- RASPBERRY PI MODEL B 700Mhz; 512Mb RAM

- http://octoprint.org/

- Transcend 8 GB Class 10 SDHC Flash Memory Card (TS8GSDHC10E)

- Kingston Digital DataTraveler SE9 32GB USB 2.0 Flash Drive (DTSE9H/32GBZET)

- Kingston Digital 16 GB Class 4 microSDHC Flash Card with SD Adapter (SDC4/16GBET)

- Belkin USB 2.0 4-Port Ultra-Mini Hub

- Micro USB to USB OTG Adapter Cable

- USB 2.0 A-Male to A-Female Extension Cable (9.8 Feet/3.0 Meters)

- C&E USB to Micro-USB Cable - 6 Ft Offered by WellGoal.

- ScotchBlue Painter's Tape, Multi-Use, 1.88-Inch by 60-Yard, 1-Roll Offered by Amazon.com.

Building Energy Monitoring

- http://openenergymonitor.org/emon/openbem

- had a quick look through: http://openenergymonitor.org/emon/guide to get some orientation

Building thermal performance monitoring and modelling

- Context**

Measuring building thermal performance: http://openenergymonitor.blogspot.co.uk/2013/09/measuring-building-thermal-performance.html

- Theory**

- Simple 3 stage dynamic building model theory: http://openenergymonitor.org/emon/node/2999

- Radiator model (documentation in progress): http://openenergymonitor.org/emon/node/3011

- Heatpump model (documentation in progress): http://openenergymonitor.org/emon/node/3021

- Software**

- Emoncms Module: OpenBEM implements 3 stage dynamic model:

- https://github.com/emoncms/openbem

- Web App (Try it!): Heating period explorer: http://www.emoncms.org/openbem/heatingexplorer

- Web App (Try it!): Heatpump efficiency explorer: http://www.emoncms.org/openbem/heatpumpexplorer

- Older heat flow simulation: http://vis.openenergymonitor.org/dev/heatflow01/

- Steady state model documentation**

- Emoncms.org: Building Energy Modeling introduction: http://www.emoncms.org/sap/introduction

- Emoncms.org: Building fabric thermal conduction: http://www.emoncms.org/sap/fabricheatloss

- Emoncms.org: Ventilation and Infiltration: http://www.emoncms.org/sap/airchange

- http://openenergymonitor.blogspot.com/2013/06/building-energy-modelling-simple.html

- http://openenergymonitor.blogspot.com/2013/06/building-energy-modelling-ventilation.html

- http://openenergymonitor.blogspot.com/2013/06/how-much-energy-does-it-take-to-heat.html

- http://openenergymonitor.blogspot.co.uk/2013/06/building-energy-modelling-part-2-first.html

- http://openenergymonitor.blogspot.co.uk/2013/06/building-energy-modelling-part-1-whole.html

- Open Office spreadsheet version of SAP 2009 thanks to Wookey: http://wookware.org/files/SAPWorksheet9.80.ods

Lulzbot Tuning

- Every time a print started the z-axis motors were trying to turn faster than they actually could so following http://forum.lulzbot.com/viewtopic.php?f=8&t=85 I set a limiter using m-code: M203

- Setting max Z speed in Slic3r? is it possible?

You can set the firmware max speed with an M code:

X axis: 11,500 mm/min (192 mm/sec) Y axis: 12,500 mm/min (208 mm/sec) Z axis: 250 mm/min (4 mm/sec)

- Then just send the following command to the firmware:

M203 X192 Y208 Z4

...and now the machine will never move faster than those settings, even if the g-code or printer host software commands it to. The same will probably apply to the TAZ and the HydraFabber printers.

Tuesday Nov 26, 2013

Input

- http://www.lulzbot.com/?q=blog/upgrade-your-ao-100

- Thinking about grounding / noise read http://opensourceecology.org/wiki/Plasma_Cutter_Design and http://www.interferencetechnology.com/designing-electronic-systems-for-emc-grounding-for-the-control-of-emi-3/

Output

- Printed out TAZ user manual, read through some of it.

- Setup a repair station

- Continued upgrading the Lulzbot to reduce by printing two of these: http://www.thingiverse.com/thing:32900

- Made some "ABS Glue" using acetone and ABS (marked with a hazardous substance safety sticker and clearly labelled)

- Prepared tables for making 3d printers + soldering electronics

- Looked at http://www.thingiverse.com/make:42492 and started thinking about tooling up one of the Equipment/Taz for PCB / CnC Milling vis https://github.com/CCHS-Melbourne/HackCNC. (also note: http://www.arduinominiconf.org/index.php/HackCNC_Assembly_Tips)

- Printed http://www.thingiverse.com/thing:15337/#files for my kindle to stand on my work desk (in preparation for auto backup + formatting of wiki for kindle - connected with ISO / cd generation)

- Started playing with http://reprap.org/wiki/PWM_Driver_1_1 note: (two more as kits to solder up!)

Spare time

- looking at hacks on ladyada website: http://www.ladyada.net/make/index.html and getting some inspiration

- This rocks: http://www.ladyada.net/make/wavebubble/index.html as does this: http://www.ladyada.net/make/tweetawatt/index.html

- I am going to make one of these asap: http://learn.adafruit.com/diy-welded-bike-stand

Monday Nov 25, 2013

- Setup table for 3 3D printers in preparation for them all being repaired and networked via hal9000 laptop/server using botqueue.com

- Currently the Lulzbot is online and 100% operational.

- The Hydrafabber is untested, the TAZ needs some reassembly and then testing.

- The makerbot needs a new thermistor on the nozzle- error message to that effect. Needs testing before ordering parts.

Sunday Nov 24, 2013

Input

- Looked over my old Eco Engineering Course Photos for some inspiration: https://plus.google.com/photos/110896145612785649027/albums/5459567608256244849

- Read http://media.steampowered.com/apps/valve/Valve_NewEmployeeHandbook.pdf

- Read http://opensourceecology.org/wiki/Open_Source_Philosophy

- Read about lulzbot enclosure http://forum.lulzbot.com/viewtopic.php?f=32&t=400

Output

- Printed modular filament reel holder for Equipment/Lulzbot_a0_101: http://www.thingiverse.com/thing:172267/#files and http://www.thingiverse.com/thing:172269

- Created a page on Projects/DiffusionEbooks

- Idea: Make micro in-situ printable documentation for all OSE equipment + standardise for Equipment/Name-of-Tool

Epic: upgrade Hal9000 to latest debian + reinstall fileserver, printerserver, timelapse webcam scripts, 3d printerserver

- Downloaded iso http://cdimage.debian.org/debian-cd/7.2.0/i386/bt-cd/debian-7.2.0-i386-xfce-CD-1.iso.torrent

- Checksum $ sha512sum debian-7.2.0-i386-xfce-CD-1.iso 692330e258abdaf7697ec5bac5a9d4cc7ed45dcbbc9ccf24d0f4eb0b6eb0222d89e793fceaf6c7a702d1742ecaf1c3f78ee70a1e68f8cdd147957b6be7b2e5fb debian-7.2.0-i386-xfce-CD-1.iso

- Made a bootable USB debian iso: http://www.debian.org/releases/stable/i386/ch04s03.html.en

- Setup Equipment/Taz, Equipment/Lulzbot_a0_101 and Equipment/HydraFabber

Saturday Nov 23, 2013

- Took the day off to hang out with Mike and Scott!

- Took out the recycling (photos + guide to follow).

- 3D Printed some widgets for the Hablab: 2 x classic reprap coathooks (need to print 2 more!), a mason jar handle (need to print 5 more) and a toothbrush head cover for Mike.

Friday Nov 22, 2013

Input

7:30 am

- Woke up, slept ok, bit dehydrated.

- Found there was no hot water. Scott going to check the shower / propane tank.

- Great hangout with Mike and Scott over coffee this morning

- Scott cooked an amazing breakfast.

- Read Chris Reinhart Log entry for 21st November 2013, Chris_Reinhart_Log#Longwinded_Debrief_on_FeF_Procedures_after_November_Visit:_On-Boarding_Ideas.2C_Meeting_Titles.2C_and_the_Dinner_Bell

9am meeting

- Marcin asked DPVs: would you update facebook if you were invited. There was a general aye in response.

- Marcin request for me to update my log

Feedback on meeting

- beginning 15mins of morning meeting was productive: storytelling and task assignment.

- Very little Interaction with remote participants, tech issues, mic problems, echo/feedback.

- Meeting became less productive for Rob, Katie, Audrey and Sam when the discussion turned to prototyping the workshop stove which is out of scope for all of us except Mike, Scott and Marcin (signal/noise ratio decreased!).

- There were no introductions made for Mike, and little to no onobarding took place, morning plan: he will be shadowing Marcin and Scott in the workshop to install the stove and then mabe looking at roads / surfacing.

- Reminder: essential to upoload ~9:10am Friday 22nd November 2013 videos / stories to youtube and link from Logs! Source: Stories from this morning are on Marcin's Tablet and Sam's G3.

- Key Takeaways:

- story telling good

- task assignment good

- need to stay focused on torch table, process efficiency and general team wellbeing

- bail on future meetings at the point when the signal to noise ratio goes down w.r.t. CnC Torch Table (reason: not in scope) i.e. a prototyping meeting style on a module / project I am not working on, this will prevent frustration and save about 50mins of peak concentration/working time / day.

10am to 1pm: Morning work session

- Getting distracted by having to answer the telephone and the cat going nuts / running around.

1pm to 2pm

- Lunch!

2pm to 5pm: Afternoon work session

- Find Mic, Camera and Speakers for Mac Mini

- Read: Audrey’s Workshop Organization & OSHA/Safety Notes

5pm: Free time

- 3d printer audit -> purchase list for repairs

- Check hal9000 after ubuntu 12.04 upgrade

- Create Mashup between OSE Wishlist and Freecycle Missouri

Output

- Printed out Chris_Reinhart_Log#Longwinded_Debrief_on_FeF_Procedures_after_November_Visit:_On-Boarding_Ideas.2C_Meeting_Titles.2C_and_the_Dinner_Bell to the notice board.

- Personally Adopted Chris' Proposed Schedule to maximise personal productivity, thanks Chris!

- Updated log from today, pending backlog to update log entries from 19th November to 21st November.

- Created a backlog: upload as many stories as possible and link from personal logs.

- Started Next task from Scrumy board: https://scrumy.com/samthetechie "Sketchup of Y Axis Drive"

- Went on a scavenger hunt in the OSE workshop for electronics parts, brough box of stuff back to hablad in order to make a little nest / electronics desk/woskbench.

- Created a list of electronics workshop items to be purchased from Adafruit and Amazon

- Fixed Lulzbot 3D Printer: installed new PSU, took off old extruder due to failed resistive heating element and installed new one.

Thursday Nov 21, 2013

- Met Mike, our new DPV.

- Full day of errands and shopping: car parts, tools, essentials, groceries

- Had lunch with Mike and Scott at the Red Barn, later on we went for a beer in Cameron

Monday Nov 18, 2013

Input

- http://opensourceecology.org/wiki/Paul_Log#Capacitive_Height_Sensor_30_July

- Identify Useful Background Material from MIT OCW:

Todo

- Differential Equations

- Multivariable Calculus

- Mechanics & Materials I

- Dynamics and Control I

- Finite Element Analysis of Solids and Fluids I

- Finite Element Analysis of Solids and Fluids II

Done

- Physics I: Classical Mechanics (will play videos in hablab in background as a refresher because this is such an awesome course- the teacher is so charismatic :)

Output

- Read through Lecture 1: http://ocw.mit.edu/courses/mechanical-engineering/2-092-finite-element-analysis-of-solids-and-fluids-i-fall-2009/lecture-notes/MIT2_092F09_lec01.pdf

- Made the OSE Wishlist, based on https://www.cryptoparty.in/organize/support

Sunday Nov 17, 2013

Input

- Sat in on morning standup / scrum. Mostly the discussion was about the Trencher because this was, in fact, a prototyping meeting and not a scrum meeting. Thanks to

Output

- Handed scrum master role to Chris for the morning.

- Suggested a new process intended to maintain internal narrative / story telling and also external narrative / storytelling: each member of the scrum to tell a story for 2mins, recorded on a smartphone and uploaded to youtube.

- Started to make a technology check spreadsheet: to *actually* get a realistic staus check and then target + offer help to teammates that did not install / use the software/process listed here: http://opensourceecology.org/wiki/Onboarding

- Went to hide and do background reading on CNC Torch Table ready to start working on it while the others went to the workshop

- Katie arrived with the keyboard for the Mac Mini, I installed it ASAP so it is ready for the guys to use during next brainstorm or hangout in the hablab (priority because this was so frustrating yesterday, nobody could connect their laptop to the main screen and it wasted a *lot* of meeting time and energy- thanks again for the keyboard and mouse Katie!) :p

- Setup mac mini, named skynet: https://www.youtube.com/watch?v=4DQsG3TKQ0I

- Found a load more cables and consolidated into the cable storage at the back of the fablab

- Needed to print something for information but could not so I switched back to infrastructure

- Plugged the 2D (normal) printer into hal9000 and enabled printer sharing, printer status: working

- Plugged the Ultimakers into hal9000

- Tested uploading a file to new OwnCloud file server on hal9000

Status on Checklist for DPV Orientation

Done

- Learn Sketchup Tutorial 1, Sketchup Tutorial 2.

- Start a Work Log according to Work Log Standards.* Begin playing with laser cut foldup models of LifeTrac Construction Set.

- Access to Dozuki Wiki, OSE Wiki.

- Begin playing with laser cut foldup models of LifeTrac Construction Set.

Backlog

- To get credit for your work in a transparent way, post any contributions to Contributor Log Form

- Log into Trovebox for picture uploads, and OSE YouTube/Vimeo for videos.

- Sign up for Design Sprints and collaborate with other Design Sprint Participants.

Saturday Nov 16, 2013

Input

- Trencher Model File:Trencher review sketchup v8.skp from Chris_Reinhart_Log + minor changes requested by marcin

- http://opensourceecology.org/wiki/Trencher_2_Development_Board

- https://docs.google.com/drawings/d/1xbt7FW9REe9pzf_vhH28DL22OAF2iAMpdyJ4liOQ3BU/edit

- Update this: http://opensourceecology.org/wiki/LifeTrac_6_Modular_Wheel_Units_-_Visual_Bill_of_Materials to "universal rotor" and add to dev docs

Output

- Setup kanban board in the hablab

- facillitated a scrum at 9am as Scrum Master

- Brainstormed with the guys about spool / cable feeding for the trencher

- Did a walk around in the hablab to identify things to repair and get to know where things are

- Did a walk around the site to get to know the site layout a bit better. Need a guided tour from user:Marcin, will request.

- Had a look at the

- Helped to pack away the new nuts, bolts and washers that were delivered

- Took a ride into town with Katie to look at what was there and get a little bit of local information / orientation

- Shadowed and helped Marcin in the workshop a bit, moving metal parts, finding tools, removing

- Used the compressed air machine with pnematic parts to assist in cleaning dusty storage boxes.

- Reorganised the bolts and nuts and washers by size, type and made it consistent between the shelves

- Moved the rollable tool drawers back to their position in terms of the Workshop map.

- Hacked the (forgotten) root pw of marcin's oldthinkpad / ubuntu and updated it to Ubuntu 10.0.4

- Installed OwnCloud on hal9000

- Setup botqueue.com account for our 3 3D printers

- hostname: hal9000 (after Hal 9000 from ’2001: A Space Odyssey’)

- video: https://www.youtube.com/watch?v=6MMmYyIZlC4

Friday Nov 15, 2013

A *really* terrible selfie of me after a very long flight - Day 0 of my DPV!

A *really* terrible selfie of me after a very long flight - Day 0 of my DPV!

Sat, Oct 19, 2013

- Added info to dpv app (draft): samthetechie DPV app

Sun, Jun 16, 2013

Input

- AI 1: read updates from Brian, Chris, Cory and Jordan.

- Brian_Log#Sat_Jun_15.2C_2013 and Brian_Log#Fri.2C_June_14.2C_2013

- Chris_DeAngelis_Log

- Cory_Shenk's_Log#June_15.2C_2013:_Backhoe_Pivot vis. pivot module to update models / assemblies

- Jordan_Log#Friday.2C_June_14.2C_2013

- File:Backhoe pivot.skp

- AI 2: stream in updates to models and parts in order to bring these models up to date: File:Reinforced Backhoe With Articulated Pivot.skp and File:3DLifeTracAndBackhoe.skp

Sat, Jun 15, 2013

- As per AI 3 + AI 4:

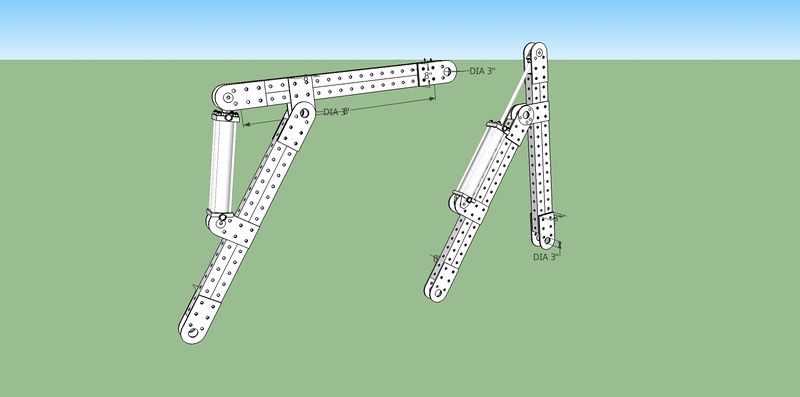

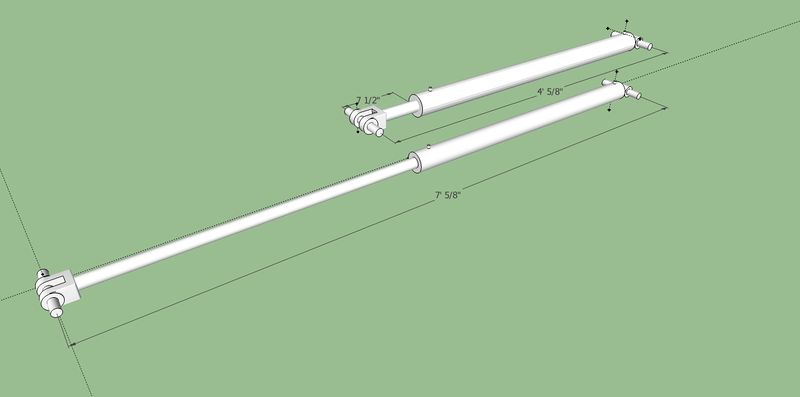

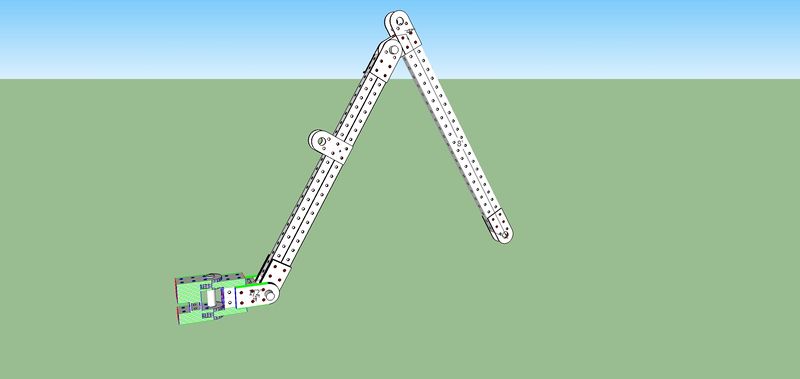

- Updated stick range with the following feedback from Marcin et al. during hangout

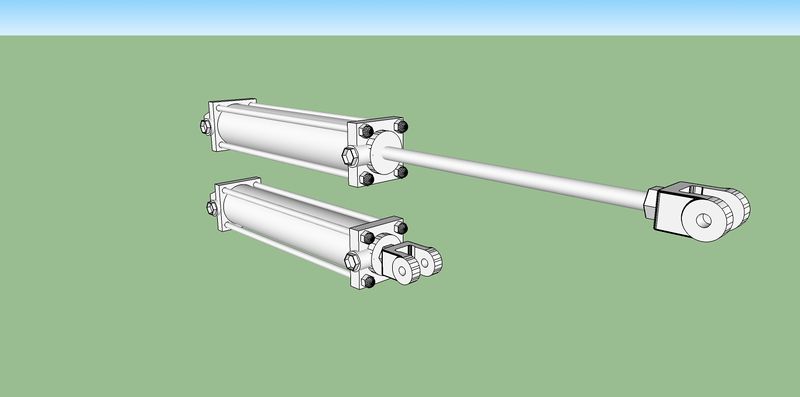

- removed old hydraulic cylinder (2.5x36x1.5): File:Hydraulic Cylinder 2.5 inch bore 36 inch stroke.skp

- added new hydraulic cylinder (3x30x1.5): File:3x30x1.50 DIA CYL.skp

- changed 8 foot length 4" x 4" by 1/2" thick SHS with 6 foot lengths.

- File:Stick range.skp

- As per AI 2:

- File:Stick.skp

- As per AI 1: File:3x30x1.50 DIA CYL.skp

Inputs

Read Updates from:

- Brian_Log#Fri.2C_June_14.2C_2013

- Cory_Shenk's_Log#June_14.2C_2013

- Looked at Cory's Models:

- File:Stick range.skp

- File:Boom range.skp

- Looked at 3 x 30 x 1.5 DIA CYL (LH 3000)

- Product Page: https://www.surpluscenter.com/item.asp?item=9-8262-30&catname=hydraulic

- Tech Specs: http://www.monarchindustries.com/lion-hydraulics/tie-rod-cylinders/lynx/lh/lh-3000-technical-specs/

- Hi-res image: http://www.northerntool.com/images/product/zoom_images/24590.jpg

- Sell sheet: http://www.monarchindustries.com/lion-hydraulics/wp-content/uploads/LH3000-Sell-Sheet-Electronic-Version-231175-R1-1.12.pdf

- Emailed Brian about CAD, emailed Audrey about CAD.

- AI 1: Model new cylinder 3 x 30 x 1.5 DIA CYL (LH 3000)

- Found: http://sketchup.google.com/3dwarehouse/details?mid=5f3b4629c3bffb773c7deb10805d9ee5&prevstart=0

- Adapting Model to scale and editing features.

- AI 2: update File:Stick.skp and File:Boom.skp

- AI 3: update File:Boom range.skp and File:Stick range.skp to use 6' stock rather than 8'.

- AI 4: update File:Boom range.skp and File:Stick range.skp to have new cylinder created in AI 1.

Sat, Jun 1, 2013

- Reviewing Wiki recent changes to get up to speed for this weekend's design sprint.

- First Draft of the Hyrdaulic Cylinders:

File:Hydraulic Cylinder 2.5 inch bore 36 inch stroke.skp

- Not work per se but: backhoe driver uses hydraulics to climb into a truck ready for transportation! https://www.youtube.com/watch?v=6hfUWcrqPP4

Sat, May 25, 2013

Input

Output

- Uploaded some more stock parts / individual components for others to reuse / remix:

- File:Articulated Pivot.skp

- Discussed FEA / Analysis with User:Marcin

- Useful Resources on FEA (Finite Element Analysis):

- 2.092 Finite Element Analysis of Solids and Fluids I

- 2.094 Finite Element Analysis of Solids and Fluids II

- Matlab FEA Software

- Solidworks FEA

- Sketchup Frame 3dd frontend Plugin Demo Video

- Frame 3dd Sourceforge Project

- Frame 3dd Interface Plugin]

- Frame3DD Sketchup Interface - Discussion about the plugin on sketchucation.com/forums

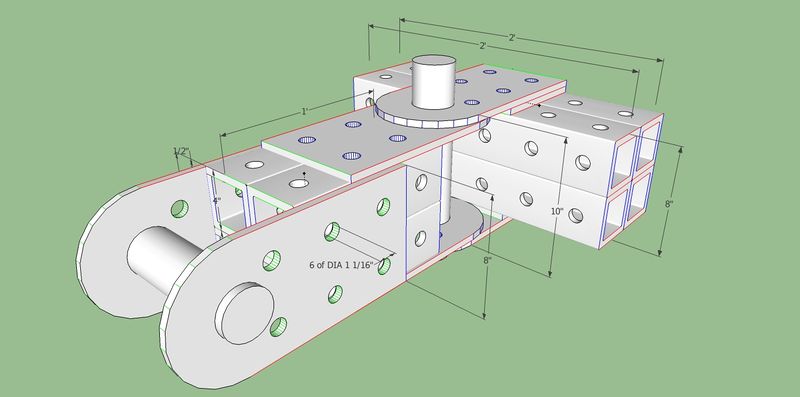

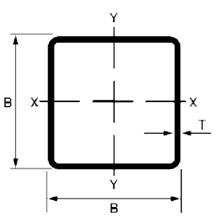

Note in the discussion that the modelling is done with 1" x 1" by 2mm thick SHS (Square Hollow Section). It is quite likely that the modelling parameters can be altered to allow analysis of 4" x 4" by 1/2" thick SHS:

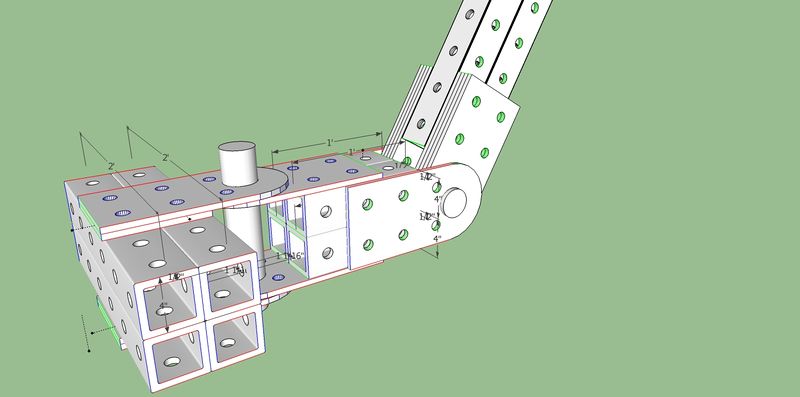

- Example arrangement of mounting the File:Reinforced Backhoe With Articulated Pivot.skp onto the File:3DLifeTrac.skp. Here is the result: File:3DLifeTracAndBackhoe.skp

- Evolved the previous design to reinforce by stacking plates: File:Reinforced Backhoe With Articulated Pivot.skp

- This is just a first thoughts / assembly of parts into one document: File:Backhoe With Articulated Pivot.skp Having watched Backhoe Concept video from User:Marcin I will heavily edit / evolve this model:

- This model is just an example assembly to start to see how it would take shape: File:Backhoe With Articulated Pivot.skp, final model will go here File:Backhoe Articulated Pivot.skp

- Evolving articulated pivot design based on CAD / images found at

, GrabCAD_Backhoe_Redesign_for_Fabrication,

, GrabCAD_Backhoe_Redesign_for_Fabrication,  , GrabCAD:lifetrac-backhoe, GrabCAD lifetrac-backhoe winner and mainly Backhoe Concept video from User:Marcin

, GrabCAD:lifetrac-backhoe, GrabCAD lifetrac-backhoe winner and mainly Backhoe Concept video from User:Marcin

- Wrote a quick guide for Sketchup_on_Linux

- Note: quick way to grab all the .skp files that have been uploaded onto the wiki.

Go to Special:ListFiles&limit=500&ilsearch=.skp and then using the down them all plugin for firefox and 'fast filtering' with /(.skp)$/

- Some notes on edge alignment in sketchup that I found useful today:

"A second method for ensuring your edges are aligned to axes is to temporarily change the colors of your edges to reflect their alignment to one of the axis. To change edge colors to reflect axes colors."

- Reviewing recent wiki changes and latest pages relating to the Backhoe:

- OSE-OSHW-Dev-Backhoe

- Brian_Log

- Marcin_Log

- Backhoe_Boom_in_Sketchup was last updated on 06:19, 18 May 2013 by User:Marcin so it is out of date.

- Backhoe Prior Art - Marcin

- Backhoe_Stick_and_Boom_Concept_Specification#Response - points 1-3 of this response were addressed by editing the components, points 4-6 can be addressed by creating models sub-assemblies and assemblies today.

- Backhoe_Development_Brief - looks like a todo list for today

- Backhoe_Pivot_Module_Academy - new page, no content yet.

Tues, May 21, 2013

Input

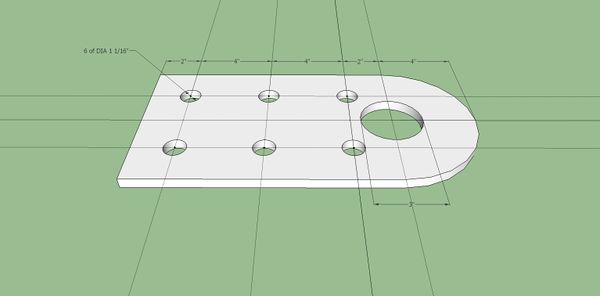

- File:Stock Pivot Plate.skp

- Feedback from User:Marcin about File:Backhoe.skp

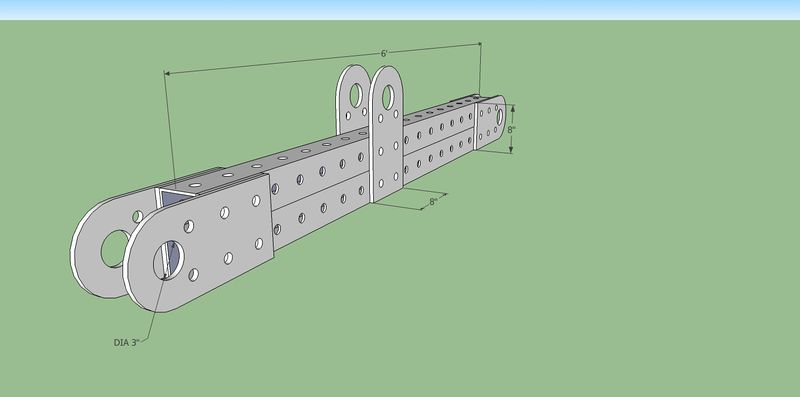

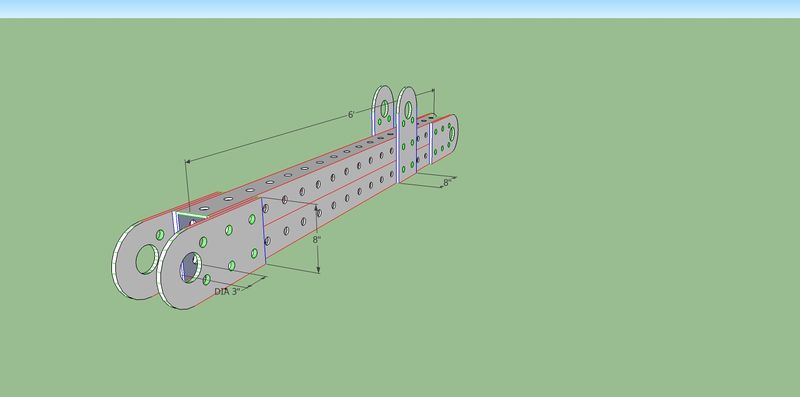

To generate a CAM file for 3D printing, one must consider the 3" tubing and print out a 3" hole, not a 4.875" hole and ensure hole is correct for 3d printed files.

- New pivot plate File:Stock Pivot Plate 3 inch hole.skp should address feedback from User:Marcin about the 3" pivot hole.

Note: the above is used to generate a CAM file for 3D printing, one must consider the 3" tubing and print out a 3" hole

Ouput

- Updated File:Backhoe.skp with new 'mouse ear' Stock_Pivot_Plate

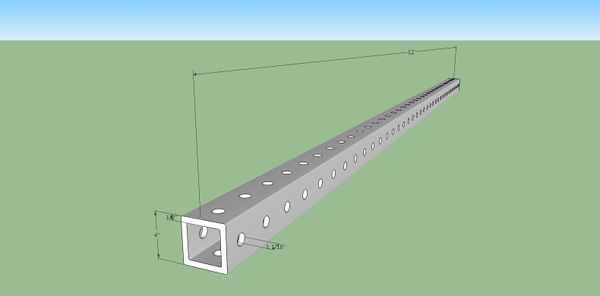

- File:12 foot stock 4 inch square tube with half inch walls.skp

- File:11 foot stock 4 inch square tube with half inch walls.skp

- File:10 foot stock 4 inch square tube with half inch walls.skp

- File:9 foot stock 4 inch square tube with half inch walls.skp

- File:8 foot stock 4 inch square tube with half inch walls.skp

- File:7 foot stock 4 inch square tube with half inch walls.skp

- File:6 foot stock 4 inch square tube with half inch walls.skp

- File:5 foot stock 4 inch square tube with half inch walls.skp

- File:4 foot stock 4 inch square tube with half inch walls.skp

- File:3 foot stock 4 inch square tube with half inch walls.skp

- File:2 foot stock 4 inch square tube with half inch walls.skp

- File:1 foot stock 4 inch square tube with half inch walls.skp

Sat, May 18, 2013

- Progress on 18th: Working on sketchup models for OSE-OSHW-Dev-Backhoe

Input

- explanation and orientation from marcin about the Backhoe.

- shown key documents/resources:

- Backhoe dev page: OSE-OSHW-Dev-Backhoe

- Backhoe sketchup models in a zip file: Backhoe_Boom_in_Sketchup (my starting point for the day in terms of sketchup source files).

- Backhoe Prior Art

Output

- File:Stock Bonding Plate 8 inches x 16 inches.skp

- File:Stock Spacer Plate 8 inches x 8 inches.skp

- File:Backhoe.skp

- note 5/21/13 - needs updating to mickey mouse. DONE see new upload to File:Backhoe.skp (note the 4.875" pivot hole is still present)

- note 5/21/13 - then to 3" pivot hole for rapid prototyping / 3d printing rather than 4.875" as per explanation on Stock_Pivot_Plate