3D Printed Multiwall Greenhouse Glazing: Difference between revisions

No edit summary |

No edit summary |

||

| Line 1: | Line 1: | ||

=Prototype= | =Prototype= | ||

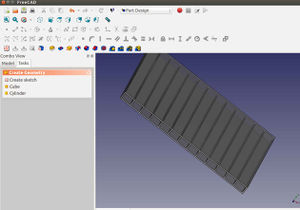

[[File:3dpglazing.jpg|thumb|Multiwall ABS print, next step is transparent polycarbonate. May 2016.<html><iframe width="300" height="175" src="https://www.youtube.com/embed/FndHDbMZI1c" frameborder="0" allowfullscreen></iframe></html>]] | [[File:3dpglazing.jpg|thumb|Multiwall ABS print, next step is transparent polycarbonate. May 2016. Download source file in FreeCAD or STL to try this yourself - [[File:twinwall.tar.gz]] <html><iframe width="300" height="175" src="https://www.youtube.com/embed/FndHDbMZI1c" frameborder="0" allowfullscreen></iframe></html>]] | ||

=Info= | =Info= | ||

Revision as of 06:01, 21 May 2016

Prototype

Info

Studying Solexx for 4' wide double wall stabilized polyethylene glazing with 10 year lifetime - it costs $8 per foot of length, or $2/sf - [1]. This is more expensive than twin-wall polycarbonate.

If one foot weighs one pound - the materials cost using 3D printing would be quite expensive - $10. This is more expensive than the finished product.

One has to turn to producing their own filament - say from pellets - which are $1 per pound, or recycled sources, which can be lower.

At $1/lb - we can consider high performance greenhouse at 25 cents per square foot, almost 10x lower cost than Solexx. Multi-wall glazing can also be printed.

- How about polycarbonate? See data on strength - [2].

Has DIY polycarbonate filament extrusion happened? Yes - see [3]

Thus, where do we get polycarbonate pellets? For example - [4]

UV Stabilizers

- 3 main stabilizers - [5]

Links

Consultants

- PolymerTechnology and Services - [8]