Keyline Plowing: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

|||

| Line 28: | Line 28: | ||

*Shank is 1"x6" mild steel | *Shank is 1"x6" mild steel | ||

*Tip should be welded with tungsten powder | *Tip should be welded with tungsten powder | ||

=Suggestions and Comments= | |||

<html><iframe src="https://www.facebook.com/plugins/post.php?href=https%3A%2F%2Fwww.facebook.com%2FOpenSourceEcology%2Fposts%2F10154944405041562&width=500" width="500" height="427" style="border:none;overflow:hidden" scrolling="no" frameborder="0" allowTransparency="true"></iframe></html> | |||

=Links= | =Links= | ||

Revision as of 05:39, 9 June 2016

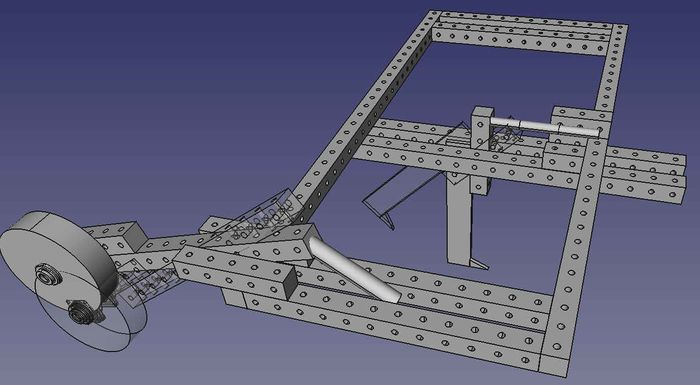

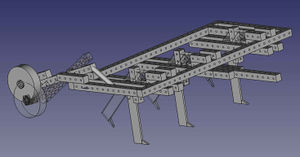

OSE Keyline Plow with Hydraulic Release

(note: wheel shown on one side only, other side is identical. Lifted position of keyline shank is shown)

.

Design Rationale

- Modular wheels

- Raisable wheels

- Hydralic cylinder with pressure relief (not hydraulic accumulator) is used for release

- Valve operated return-to-soil via control valve in cab

- 3' shank length total, 2' depth max

- Shank release angle is 45%, using an 3"x8" hydraulic cylinder

- 1" pivot through box beam tubing serves as shank pivot point

- Shank is welded to 12" of box beam tubing

- Height adjustment occurs via hydraulically lifted wheels, or via adjusting height via pin on the box beam tubing

- Designed around Universal Drawbar

- Designed for up to 4 shanks at 2' spacing

- Extensible in width by adding more box beam tubing

- Modular coulter wheels are attachable in front of shanks

- Designed for carrying fluid (water, compost tea, etc) on top of frame.

- Idler wheels can be doubled for a total of 6400 lb load capacity on wheels (1600 lb each wheel)

- Wheels are car donuts with two 1-7/8" bearings

- Shank is 1"x6" mild steel

- Tip should be welded with tungsten powder

Suggestions and Comments

Links

- Winged tip vs conventional tip subsoilers - [1]

- Yeomans discussion - soil can be built up with keyline plowing faster than it can be eroded

- Graham chisel plow from last link:

- Next