Rubber Extruder: Difference between revisions

Jump to navigation

Jump to search

(→Intro) |

|||

| Line 2: | Line 2: | ||

This is work on a rubber-optimized 3D printer 3mm extruder. | This is work on a rubber-optimized 3D printer 3mm extruder. | ||

=Working Document= | |||

<html><iframe src="https://docs.google.com/presentation/d/e/2PACX-1vStvIoyN2ekYW9jvpvjjyLIzo0xV0bXxDVj2OHjyvaWrTQ8idbs4YdVMZWhEpzcBI8TcaeQBZcDOx-0/embed?start=false&loop=false&delayms=3000" frameborder="0" width="480" height="299" allowfullscreen="true" mozallowfullscreen="true" webkitallowfullscreen="true"></iframe></html> | |||

[https://docs.google.com/presentation/d/1YXDye7YEDvVF4IjwahPZLLduxRA3UE-OymgHhMkZKHo/edit#slide=id.g1861bf60d5_0_6 edit] | |||

=Design Rationale= | =Design Rationale= | ||

Revision as of 11:34, 23 April 2019

Intro

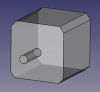

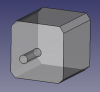

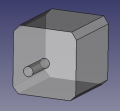

This is work on a rubber-optimized 3D printer 3mm extruder.

Working Document

Design Rationale

- Use Nema 17 motor with 3x geardown

- Use double drive wheel extruder for better grip

- Move drive wheel down as far to the nozzle as possible

- Use a clamp-on nozzle

Part Library

- Rubberextruder v1904.png

OSE Rubber Extruder - FreeCAD -File:Rubberextruder v1904.fcstd

Extruder Motor - FreeCAD -File:Extrudermotor v1904.fcstd

- Extrudergeardown v1904.png

Extruder geardown assembly - FreeCAD -File:Extrudergeardown v1904.fcstd