Basic Economic Analysis of Printing with Large Nozzles: Difference between revisions

Jump to navigation

Jump to search

(Created page with "=1.2 Nozzle, 0.4 Layer Height= 45 minutes per printed piece for Universal Axis Carriage: File:basic12econ.png") |

No edit summary |

||

| (One intermediate revision by the same user not shown) | |||

| Line 2: | Line 2: | ||

45 minutes per printed piece for Universal Axis Carriage: | 45 minutes per printed piece for Universal Axis Carriage: | ||

[[File:basic12econ.png]] | 30 grams per piece - means we can print 33 of these on one spool. | ||

[[File:basic12econ.png|400px]] | |||

For $16/spool PLA filament, material is $16 for 33 of the pieces, or 50 cents per piece. | |||

Total print would be 25 hours. | |||

Per hour of print time, charging $1-2 would be an efficient cost to produce one part per hour. This is much better than anyone else out there. ($10/part quoted elsewhere). | |||

$2/printer hour would be a solid business. Even at $1/printer hour could be a super lean business. | |||

This is assuming large nozzles, so these economics would not work for 0.4 nozzles, and the $10 per piece begins to make sense. | |||

Latest revision as of 18:28, 30 March 2020

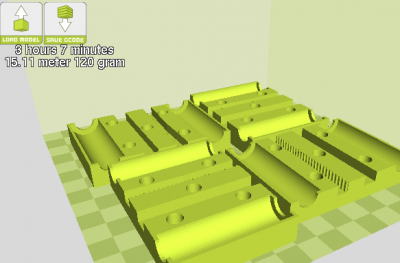

1.2 Nozzle, 0.4 Layer Height

45 minutes per printed piece for Universal Axis Carriage:

30 grams per piece - means we can print 33 of these on one spool.

For $16/spool PLA filament, material is $16 for 33 of the pieces, or 50 cents per piece.

Total print would be 25 hours.

Per hour of print time, charging $1-2 would be an efficient cost to produce one part per hour. This is much better than anyone else out there. ($10/part quoted elsewhere).

$2/printer hour would be a solid business. Even at $1/printer hour could be a super lean business.

This is assuming large nozzles, so these economics would not work for 0.4 nozzles, and the $10 per piece begins to make sense.