Angle Frame Connector: Difference between revisions

Jump to navigation

Jump to search

(→CAD) |

|||

| (5 intermediate revisions by the same user not shown) | |||

| Line 26: | Line 26: | ||

[https://docs.google.com/presentation/d/1IMkn4Z2OzDK-a8yy_De53_cd9d2_HGMtivGpcpdgdHw/edit edit] | [https://docs.google.com/presentation/d/1IMkn4Z2OzDK-a8yy_De53_cd9d2_HGMtivGpcpdgdHw/edit edit] | ||

[[File:Setscrew_mechanism.fcstd]] | |||

=Build= | |||

<html><iframe src="https://www.facebook.com/plugins/post.php?href=https%3A%2F%2Fwww.facebook.com%2Fmarcin.jakubowski.378%2Fposts%2F10218539045004527&show_text=true&width=552&height=400&appId" width="552" height="400" style="border:none;overflow:hidden" scrolling="no" frameborder="0" allowTransparency="true" allow="encrypted-media"></iframe></html> | |||

=Production= | =Production= | ||

==D3D Pro== | |||

*50% infill for real print. | *50% infill for real print. | ||

*Test print at 20%: 10 cm cut off the bottom, standing on corner - . This would not stand on moving-bed printers. Babystepping correction -0.75. It does not stand on a stationary bed printer eiether. I turned it around to print standing on 6 points. | *Test print at 20%: 10 cm cut off the bottom, standing on corner - . This would not stand on moving-bed printers. Babystepping correction -0.75. It does not stand on a stationary bed printer eiether. I turned it around to print standing on 6 points. | ||

| Line 40: | Line 46: | ||

[[File:cornerproductionengineering.png|500px]] | [[File:cornerproductionengineering.png|500px]] | ||

==D3D Simple== | |||

<html><iframe src="https://www.facebook.com/plugins/post.php?href=https%3A%2F%2Fwww.facebook.com%2Fmarcin.jakubowski.378%2Fposts%2F10217845988518548&width=500" width="500" height="378" style="border:none;overflow:hidden" scrolling="no" frameborder="0" allowTransparency="true" allow="encrypted-media"></iframe></html> | |||

Printer profile - [[File:d3duniversal_7.ini]] - 100%, see support parameters. | |||

Support parameters: | |||

[[File:supportparameters.png|500px]] | |||

Results: | |||

#100% infill - no way. Not enough stick to bed, starts warping after excellent first layer. | |||

#100% infill - roughed up surface with sand paper, 8 line brim. No way. Still comes right off. | |||

#Painter's tape - reduce infill to 20% for a less solid part but still bootstrappable to D3D Pro. | |||

Latest revision as of 18:01, 6 July 2020

Build

CAD

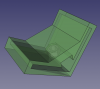

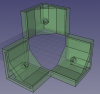

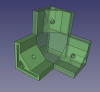

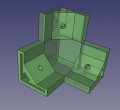

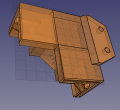

Angle Connector. - FreeCAD with McMaster 6 mm nut -File:Angleconnector.fcstd. Finished STL - File:Anglecorner.stl

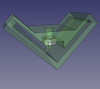

Angle Connector with axis mount, left side. - FreeCAD - File:Leftcorner.fcstd. Finished STL - File:Leftcorner.stl

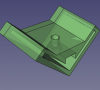

Angle Connector with axis mount, right side. - FreeCAD - File:Rightcorner.fcstd. Finished STL - File:Rightcorner.stl

Concept

Build

Production

D3D Pro

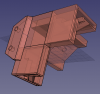

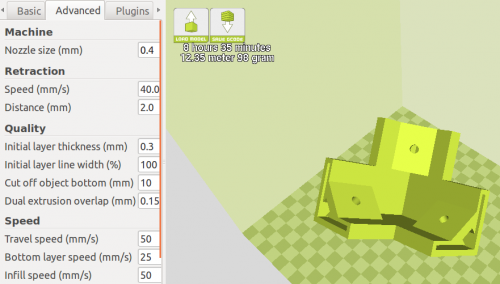

- 50% infill for real print.

- Test print at 20%: 10 cm cut off the bottom, standing on corner - . This would not stand on moving-bed printers. Babystepping correction -0.75. It does not stand on a stationary bed printer eiether. I turned it around to print standing on 6 points.

- Came off bed so printed it on 6 corners:

- Initial fit: metal shown with 6 mm hex nut and set screw in the hole.

- STL - sunk 5 mm into bed. Test print at 20%, takes 8.5 hrs. Production print: 50% infill, 10:10 hours, 133 g. Brim 10 lines. Prints starting on 6 corners, for a solid base.

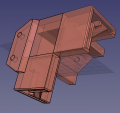

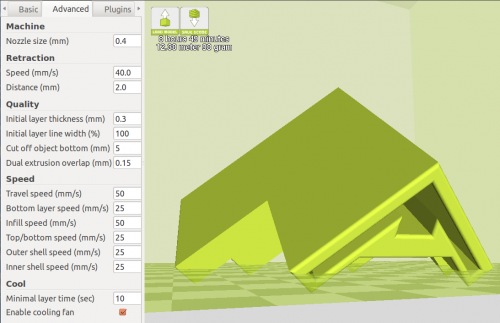

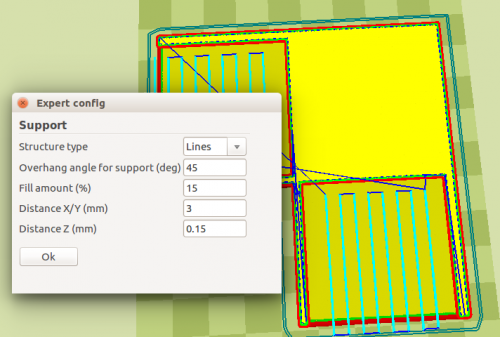

D3D Simple

Printer profile - File:D3duniversal 7.ini - 100%, see support parameters.

Support parameters:

Results:

- 100% infill - no way. Not enough stick to bed, starts warping after excellent first layer.

- 100% infill - roughed up surface with sand paper, 8 line brim. No way. Still comes right off.

- Painter's tape - reduce infill to 20% for a less solid part but still bootstrappable to D3D Pro.