Seed Eco-Home Roadmap: Difference between revisions

Jump to navigation

Jump to search

(→2022) |

(→2022) |

||

| Line 1: | Line 1: | ||

=2022= | =2022= | ||

==Rollout Narrative= | |||

==Working Doc== | |||

<html> <iframe src="https://docs.google.com/presentation/d/e/2PACX-1vR--l_lgKiTTFgbMNymagGhqsasAV0UjTptz-jLfM9TSjPGtb_dYO-o5KYq2tv2e7qm5VB7d9t1fALu/embed?start=false&loop=false&delayms=3000" frameborder="0" width="480" height="389" allowfullscreen="true" mozallowfullscreen="true" webkitallowfullscreen="true"></iframe> </html> | <html> <iframe src="https://docs.google.com/presentation/d/e/2PACX-1vR--l_lgKiTTFgbMNymagGhqsasAV0UjTptz-jLfM9TSjPGtb_dYO-o5KYq2tv2e7qm5VB7d9t1fALu/embed?start=false&loop=false&delayms=3000" frameborder="0" width="480" height="389" allowfullscreen="true" mozallowfullscreen="true" webkitallowfullscreen="true"></iframe> </html> | ||

Revision as of 19:06, 19 August 2022

2022

=Rollout Narrative

Working Doc

Also, review the clickfunnels products from 2020:

2021

Disclaimer: this is a working pitch. Some of the deliverables in past tense may not yet be delivered.

- In 2021, we are working on build optimization for 500 hour builds of the 1000 sf Rosebud. Several iterations may be needed to get there. Theoretical Calculations for Seed Eco-Home Build Time show the theoretical mimimums, based on the number of builders and deliverables stated - and are the optimal estimate.

- We are working to reduce the cost of wall materials by 20% while increasing their longevity by 400% - by using compressed earth blocks. Thus saving $10k.

- We are working on reducing the cost of trim, siding, roofing, plumbing, electrical, lumber - with 3D printing using reclaimed plastic waste feedstock. We expect a material cost reduction of the corresponding components by $10-30,000.

- We are working on solar concrete to reduce the cost of concrete from $2000 to $200.

- We are working on reducing the cost of gravel from $600 to $60 by using urbanite instead of virgin rock.

- We are working on cost reduction via corporate team-building events to reduce labor costs by 400 hours - a for-benefit sweat-equity model.

- We are workign on a multiplayer game where poeople practice building house modules in a microfactory. People work in the microfactory to build social capital for their community. People play the vidoe games and revenue goes to construction materials.

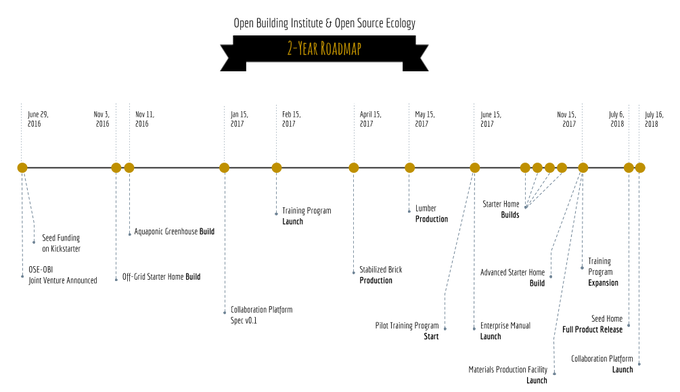

2016

- 2016 from [1]: