GVCS Cost Comparison to Industry Standards: Difference between revisions

Jump to navigation

Jump to search

(→2023) |

|||

| (One intermediate revision by the same user not shown) | |||

| Line 1: | Line 1: | ||

=2023= | |||

[[Seed Eco-Home Cost Comparison]] to Industry Standards]] | |||

=GVCS Costs - 2012= | =GVCS Costs - 2012= | ||

<html><iframe width=100% height='500' frameborder='0' src='https://docs.google.com/spreadsheet/pub?key=0Av4ZjQn4DHJHdGQ5amg2TUh5a2lNRVZSc0RKNC0xdEE&output=html&widget=true'></iframe></html> | <html><iframe width=100% height='500' frameborder='0' src='https://docs.google.com/spreadsheet/pub?key=0Av4ZjQn4DHJHdGQ5amg2TUh5a2lNRVZSc0RKNC0xdEE&output=html&widget=true'></iframe></html> | ||

Latest revision as of 00:29, 28 December 2023

2023

Seed Eco-Home Cost Comparison to Industry Standards]]

GVCS Costs - 2012

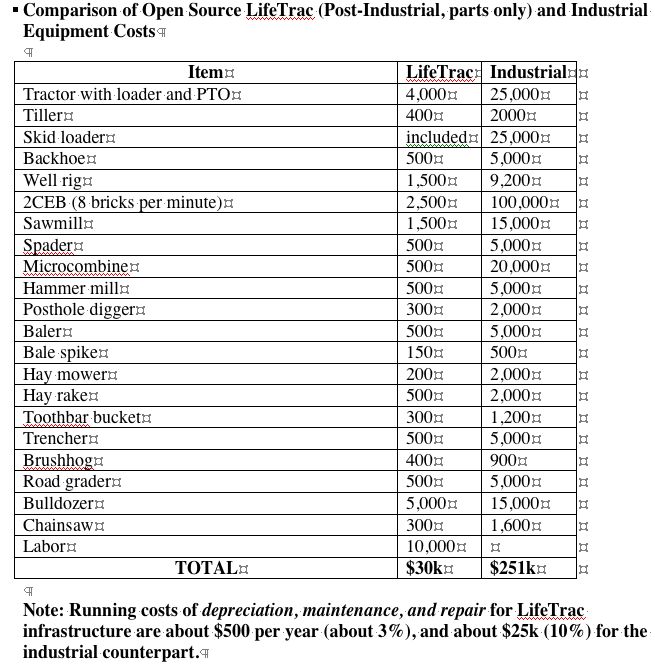

Cost Comparisons to Industrial Counterparts - 2010

- NOTE: Industrial prices are taken largely from Northern Tool catologue - [1] - your local, global supply chain.

- Commercial hydraulic rotary well drilling rig quote - [2]

- Note: Tractor and Bulldozer add up to $9k, for an infrastructure that shares wheel motors, controls, and Power Cubes. Power Cubes are $1750 each for 27 hp using off-shelf components. For about 100 hp of drive, this is $7k.

- Note: Since Power Cubes are not included here, the real cost of the package should be closer to $40k for the GVCS implementation prior to the ability to melt steel into virgin metal. This ability, combined with advanced CNC machining, will bring the cost down to about $5000 for 50,000 lbs of steel obtained from scrap sources.

- Note: Each device takes on average 1 week to fabricate after optimization to digital fabrication. This implies a total labor time of about 20 weeks for the devices above, or only $15/hour at the labor cost given. This may be acceptable for DIY value, but is a low rate for market production.