Inverter Design Rationale and Specification: Difference between revisions

Jump to navigation

Jump to search

Tom Griffing (talk | contribs) |

No edit summary |

||

| Line 2: | Line 2: | ||

=Specifications= | =Specifications= | ||

*Input – 12-120V DC | *Input – 12-120V DC using IGBTs that can handle that | ||

*Output - 12-480V AC | *Output - 12-480V AC | ||

*Plug-in transformer modules allow from 1 to 10 amplitude modification | *Plug-in transformer modules allow from 1 to 10 amplitude modification | ||

| Line 19: | Line 19: | ||

*Modular design retains allowance for different gate drivers, such as high frequency power for induction furnace power supplies and other applications | *Modular design retains allowance for different gate drivers, such as high frequency power for induction furnace power supplies and other applications | ||

=Links= | |||

IGBT Sources | |||

*http://www.shaoguang.com.cn/data/sgkj09005.pdf | |||

[[Category:Specifications]] | [[Category:Specifications]] | ||

Revision as of 00:52, 20 January 2012

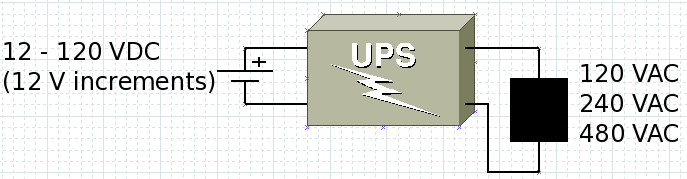

Design Rationale

Specifications

- Input – 12-120V DC using IGBTs that can handle that

- Output - 12-480V AC

- Plug-in transformer modules allow from 1 to 10 amplitude modification

- Use turnkey, plug-in IGBT module of 2.5 kW continuous, 5 kW peak

- Use turnkey, plug-in gate driver

- Use pure sine wave signal generator

- Stackable up to 10 units for up to 25kW

- Phase cable connects units so power is in phase

Scalability and Modularity Analysis

- Basic unit above provides up to 25kW continuous power

- Plug in IGBT module may be scaled for higher power, up to 250 kW for a stack of 10 inverters.

- Modular design retains allowance for different gate drivers, such as high frequency power for induction furnace power supplies and other applications

Links

IGBT Sources