Fluidized bed reactor: Difference between revisions

No edit summary |

No edit summary |

||

| Line 1: | Line 1: | ||

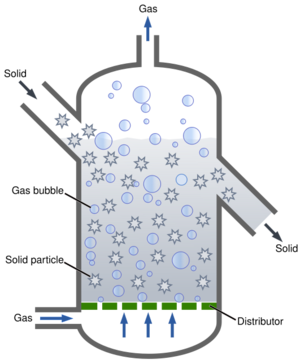

Fluidized bed reactor (FBR) are chambers that allow the mixing of liquid or gas substrates with powdered catalysts such that the catalyst acts like a fluid, maximizing mixing and catalyst action. The basic configuration is detailed to the right where a substrate is passed upward through the chamber under pressure through a plate that supports the catalyst. FBRs are essential production of many materials and chemicals and is needed for several basic capabilities of the GVCS. | [[File:Fluidized_Bed_Reactor.svg|300px|thumb|right|Fluidized bed reactor (FBR)]]Fluidized bed reactor (FBR) are chambers that allow the mixing of liquid or gas substrates with powdered catalysts such that the catalyst acts like a fluid, maximizing mixing and catalyst action. The basic configuration is detailed to the right where a substrate is passed upward through the chamber under pressure through a plate that supports the catalyst. FBRs are essential production of many materials and chemicals and is needed for several basic capabilities of the GVCS. | ||

=FBR for bioplastic production= | =FBR for bioplastic production= | ||

As part of the OSE product ecology a reactor that could be used for ethanol dehydration and ethylene polymerization is a proposed route to locally produced renewable bioplastic. Due to the nature of the subtrates, powdered catalysts, and optimal catalytic conditions FBRs have demonstrate superior performance with high process reactivity and selectivity. | As part of the OSE product ecology a reactor that could be used for ethanol dehydration and ethylene polymerization is a proposed route to locally produced renewable bioplastic. Due to the nature of the subtrates, powdered catalysts, and optimal catalytic conditions FBRs have demonstrate superior performance with high process reactivity and selectivity. | ||

Defining the machine requirements: | |||

1. Reactor chamber with ability to add or remove substrate, product, catalyst, gases, and control temperature, pressure, and the speed which substrate moves through the reactor. | |||

a. Dimensions based on reaction volume? | |||

b. Hoppers would have to be of adequate size to benefit reaction volume | |||

2. Safety: able to withstand heat and pressure, dangerous chemicals kept behind two layers of protection, product handled with precautions | |||

a. reactor materials | |||

b. design for longterm quality | |||

3. Recycling of unused substrate, carrier gas, catalyst. | |||

a. Catalyst regenerator to autoclave and activate used up catalyst. | |||

4. Saving thermal energy: isothermal or adiabatic, heat catalyst and substrate with steam depending on moisture requirements | |||

5. Control of atmosphere: gas content, increased and decreased pressure ranges, gas content in the reactor and downstream, gas mixture controls upstream | |||

6. Control and interface: sensors of pertinent conditions and an easy to understand display of the conditions, controls over conditions and inputs and outputs | |||

==Literature and patent review== | ==Literature and patent review== | ||

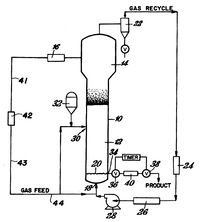

US patent 4,003,712 issued to Miller on Jan. 18, 1977 details a fluid bed reactor for use in a olefin polymerization. [[File:Us4003712.jpg|200px|thumb|right|US patent 4,003,712]] The reactor contains a reaction zone '''12''' where substrate and catalyst are combined. The substrate is supported by a fluid bed which allows the injection of substrate which allows maximum mixing due to the fluid like behavior of the catalyst. Unused substrate, catalyst, and carrier gas can be recycled through the system. Above the reaction zone is a slow down zone '''14''' where products collect and are sorted. Gas collects the velocity reduction zone and recycle gas is collected through the a line at the top of the zone. An optional cyclone '''22''' can aid in gas collection and a filter '''24''' catches small particles. A heat exchanger '''26''' acts to recycle heat and maintain the system at a constant temperature and the gas is compressed by a compressor '''28'''. | US patent 4,003,712 issued to Miller on Jan. 18, 1977 details a fluid bed reactor for use in a olefin polymerization. [[File:Us4003712.jpg|200px|thumb|right|US patent 4,003,712]] The reactor contains a reaction zone '''12''' where substrate and catalyst are combined. The substrate is supported by a fluid bed which allows the injection of substrate which allows maximum mixing due to the fluid like behavior of the catalyst. Unused substrate, catalyst, and carrier gas can be recycled through the system. Above the reaction zone is a slow down zone '''14''' where products collect and are sorted. Gas collects the velocity reduction zone and recycle gas is collected through the a line at the top of the zone. An optional cyclone '''22''' can aid in gas collection and a filter '''24''' catches small particles. A heat exchanger '''26''' acts to recycle heat and maintain the system at a constant temperature and the gas is compressed by a compressor '''28'''. New catalyst can be added through input '''30''' with a proper gas mixture and preheated, reserve catalyst is held in nitrogen in '''32'''. | ||

Revision as of 22:12, 23 March 2012

Fluidized bed reactor (FBR) are chambers that allow the mixing of liquid or gas substrates with powdered catalysts such that the catalyst acts like a fluid, maximizing mixing and catalyst action. The basic configuration is detailed to the right where a substrate is passed upward through the chamber under pressure through a plate that supports the catalyst. FBRs are essential production of many materials and chemicals and is needed for several basic capabilities of the GVCS.

FBR for bioplastic production

As part of the OSE product ecology a reactor that could be used for ethanol dehydration and ethylene polymerization is a proposed route to locally produced renewable bioplastic. Due to the nature of the subtrates, powdered catalysts, and optimal catalytic conditions FBRs have demonstrate superior performance with high process reactivity and selectivity.

Defining the machine requirements: 1. Reactor chamber with ability to add or remove substrate, product, catalyst, gases, and control temperature, pressure, and the speed which substrate moves through the reactor. a. Dimensions based on reaction volume? b. Hoppers would have to be of adequate size to benefit reaction volume 2. Safety: able to withstand heat and pressure, dangerous chemicals kept behind two layers of protection, product handled with precautions a. reactor materials b. design for longterm quality 3. Recycling of unused substrate, carrier gas, catalyst. a. Catalyst regenerator to autoclave and activate used up catalyst. 4. Saving thermal energy: isothermal or adiabatic, heat catalyst and substrate with steam depending on moisture requirements 5. Control of atmosphere: gas content, increased and decreased pressure ranges, gas content in the reactor and downstream, gas mixture controls upstream 6. Control and interface: sensors of pertinent conditions and an easy to understand display of the conditions, controls over conditions and inputs and outputs

Literature and patent review

US patent 4,003,712 issued to Miller on Jan. 18, 1977 details a fluid bed reactor for use in a olefin polymerization.

The reactor contains a reaction zone 12 where substrate and catalyst are combined. The substrate is supported by a fluid bed which allows the injection of substrate which allows maximum mixing due to the fluid like behavior of the catalyst. Unused substrate, catalyst, and carrier gas can be recycled through the system. Above the reaction zone is a slow down zone 14 where products collect and are sorted. Gas collects the velocity reduction zone and recycle gas is collected through the a line at the top of the zone. An optional cyclone 22 can aid in gas collection and a filter 24 catches small particles. A heat exchanger 26 acts to recycle heat and maintain the system at a constant temperature and the gas is compressed by a compressor 28. New catalyst can be added through input 30 with a proper gas mixture and preheated, reserve catalyst is held in nitrogen in 32.

Links

http://en.wikipedia.org/wiki/Fluidized_bed_reactor

http://www.fischer-tropsch.org/Bureau_of_Mines/ri/ri_6209/ri_6209.pdf