CNC Torch Table 2/Control Overview: Difference between revisions

m (→Torch control) |

m (→Test mule) |

||

| Line 113: | Line 113: | ||

===Test mule=== | ===Test mule=== | ||

I am not building a torch table but I need a breadboard "mule" to test software functionality. I purchased four of [http://www.ebay.com/itm/-/260312204129?item=260312204129 these] 34-frame steppers. | I am not building a torch table but I need a breadboard "mule" to test software functionality. I purchased four of [http://www.ebay.com/itm/-/260312204129?item=260312204129 these] 34-frame steppers for $10 each. | ||

[[File:SanyoDenkiStepper.jpg]] [[File:SanyoDenkiWiring.png|320px]] | [[File:SanyoDenkiStepper.jpg]] [[File:SanyoDenkiWiring.png|320px]] | ||

Revision as of 20:47, 20 October 2012

Overview

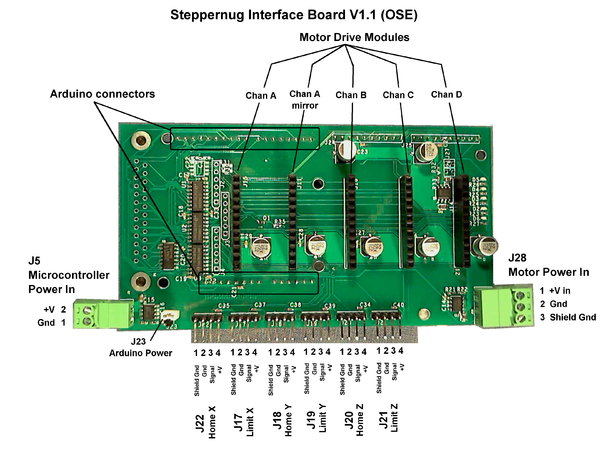

Endstops

To implement the endstops, we are modifying the GRBL file (firmware for the Arduino AVR328P) and flashing it onto the Arduino. This process requires one to understand GRBL, pinouts of Arduino, AVR chip, AVRdude uploader. GCC is used to complile c to hexadecimal.

The source code can be found at_______________ (An OSE fork on grbl github - who is making this?)

Schematic

Arduino controller pinout

Cross reference: StepperNug vs GRBL defaults (v0.7 Master, config.h)

| StepperNug Intfc V1.1 | GRBL default (ref) | |||||||

| Function | Schematic Pin |

Port | Bit | Arduino Pin |

Port | Bit | Arduino Pin |

Equiv. Function |

| Clk A | 5 | B | 5 | 13 | D | 2 | 2 | Step X |

| Dir A | 6 | B | 4 | 12 | D | 5 | 5 | Dir X |

| Clk B | 7 | B | 3 | 11 | D | 3 | 3 | Step Y |

| Dir B | 8 | B | 2 | 10 | D | 6 | 6 | Dir X |

| Clk C | 9 | B | 1 | 9 | D | 4 | 4 | Step Z |

| Dir C | 10 | B | 0 | 8 | D | 7 | 7 | Dir Z |

| Home X | 11 | D | 7 | 7 | B | 1 | 9 | Limit X |

| Home Y | 12 | D | 6 | 6 | B | 2 | 10 | Limit Y |

| Home Z | 13 | D | 5 | 5 | B | 3 | 11 | Limit Z |

| Enable | 14 | D | 4 | 4 | B | 0 | 8 | Disable |

| Spindle | 15 | D | 3 | 3 | B | 4 | 12 | Spindle enable |

| Home/Limit Interrupt |

16 | D | 2 | 2 | ||||

| B | 5 | 13 | Spindle Dir | |||||

Physical

Software

G-code prep

DXF_to_G-code_Conversion_Tutorial

Nesting software would be useful. Example commercial product here. Anything open source?

Correction for torch cut kerf width ("cutter compensation" in CNC lingo) needed. G40/G41 but grbl does not interpret these.

Gctrl(cross-platform), gcodesender(Windows). Other options for gcode streaming here.

grbl

I am starting with grbl v0.8 "edge" branch forked from https://github.com/grbl/grbl at https://github.com/chuck-h/grbl/tree/edge . ChuckH 09:19, 24 September 2012 (CEST)

grbl requires an appropriate config.h file and a patch to the stepper-enable polarity in order to work with StepperNug.

Relevant parts of config.h (pin assignments):

// Define pin-assignments #define STEPPING_DDR DDRB #define STEPPING_PORT PORTB #define X_STEP_BIT 5 // Uno Digital Pin 13 #define Y_STEP_BIT 3 // Uno Digital Pin 11 #define Z_STEP_BIT 1 // Uno Digital Pin 9 #define X_DIRECTION_BIT 4 // Uno Digital Pin 12 #define Y_DIRECTION_BIT 2 // Uno Digital Pin 10 #define Z_DIRECTION_BIT 0 // Uno Digital Pin 8 #define STEPPERS_DISABLE_DDR DDRD #define STEPPERS_DISABLE_PORT PORTD #define STEPPERS_DISABLE_BIT 4 // Uno Digital Pin 4 #define STEPPERS_DISABLE_INVERT // Logic low out for disable (e.g. steppernug) #define LIMIT_DDR DDRD #define LIMIT_PIN PIND #define X_LIMIT_BIT 7 // Uno Digital Pin 7 #define Y_LIMIT_BIT 6 // Uno Digital Pin 6 #define Z_LIMIT_BIT 5 // Uno Digital Pin 5 #define SPINDLE_ENABLE_DDR DDRD #define SPINDLE_ENABLE_PORT PORTD #define SPINDLE_ENABLE_BIT 3 // Uno Digital Pin 3 #define SPINDLE_DIRECTION_DDR DDRD #define SPINDLE_DIRECTION_PORT PORTD #define SPINDLE_DIRECTION_BIT 1 // Uno Digital Pin 13

(Note: I assigned SPINDLE_DIRECTION to an unused pin as a quick hack.)

To reverse the polarity of the stepper enable pin, I added the STEPPERS_DISABLE_INVERT flag (above) and changed stepper.c to honor it (lines 104, 124).

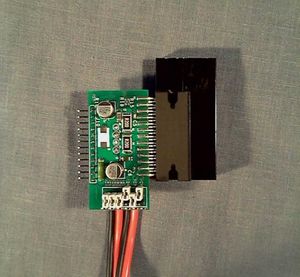

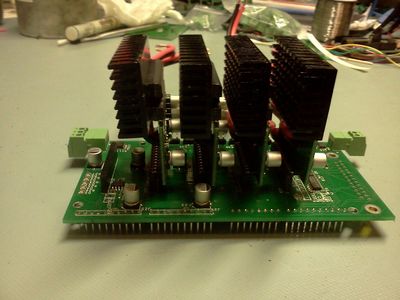

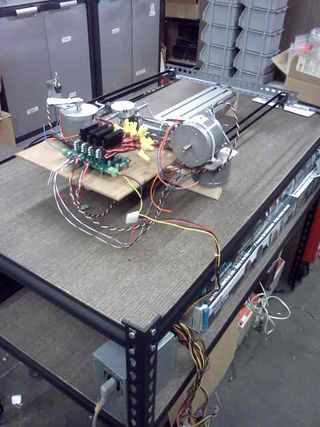

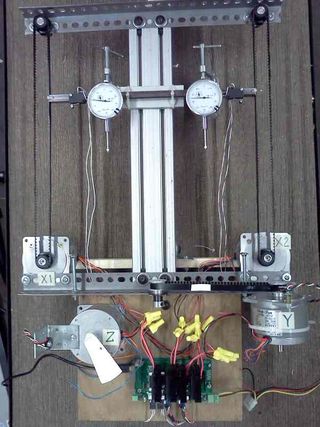

Test mule

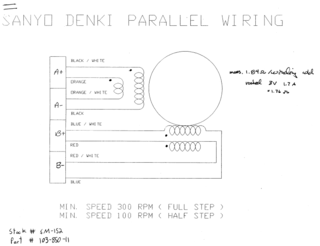

I am not building a torch table but I need a breadboard "mule" to test software functionality. I purchased four of these 34-frame steppers for $10 each.

These are split-winding (8 wire) motors so each phase can be driven either series or parallel. Each individual coil seems to be rated 3V, 1.7amp.

- First test ChuckH 02:51, 24 September 2012 (CEST)

- single coil per phase, steppernug configured for 50% of full current, full current = 2.5A, so phase current = 1.25A.

- power source: 12V

- single motor connected to channel A

- Success! G-code command "X5" issued through gcodesender causes motor to move a few rotations. Miller Time :)

Got my "test mule" put together. Checking out homing functions. ChuckH 04:47, 14 October 2012 (CEST)

Detail

so the interrupt works on INT0, active low. i'm not debouncing it, unless you want me to, but maybe that's not advised for end stop interrupts.

in my notes, i have that we want to use INTB (aka INT1) for spindle control. (i recall we also said something about that being an input for "home," but my notes are poor on this point; can you can explain what functionality you want here, Darren?)

anyway, by default, spindle enable is pb4, and spindle direction is pb5, which map to pins 8 & 9 respectively. but we're using those two pins for Z axis control currently. so we'd need another pin than INTB, at the least, tho i'm a fan of using the defaults personally.

regarding doing something with that INT0 interrupt, i.e. disabling the motors (and something with pin4, which would reenable them): is the idea that after an end stop is hit, the interrupt is thrown, the motors stop and G code stopped, and then the user manually moves the heads back to some home location, and then presses a button to reneable the motors? or do you want this interrupt to work as if was interpreting a particular gcode ( M2 comes to mind).

Zeroing

The x axis (long axis) has 2 stepper motors. These are typically coupled.

For zeroing, the x axis needs to decouple - so if we get the x axis out of parallel, we can jog the x axes back into parallel by hitting the end stops.

Torch control

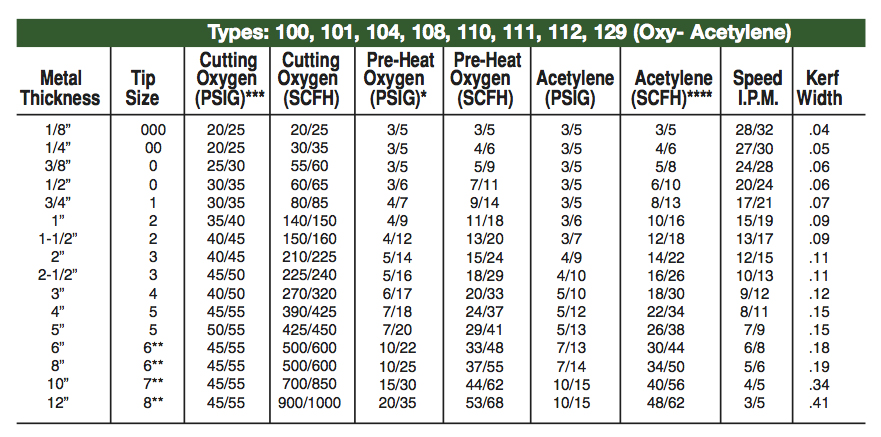

During cutting, an oxyfuel cutting torch is literally burning the steel with a blast of oxygen; most of the heat comes from oxiding the iron. However to start a new cut ("piercing") you must preheat the steel, relying on the acetylene or LPG for heat. After the steel is red hot you boost the oxygen flow and make the cut. We will want an oxygen-rated solenoid valve controlled by the steppernug. ("Oxygen-rated" mostly means the valve is thoroughly cleaned of all oil or flammable solvents that tend to explode on contact with pure oxygen.)

Recommendations from Victor: