Stock Pivot Plate: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

No edit summary |

||

| Line 2: | Line 2: | ||

[[Image:stockpivotdxf.jpg]] | [[Image:stockpivotdxf.jpg]] | ||

Note: the correct large hole diameter in the above is 4.75", which gives 1/8" room around the DOM for effective welding. | |||

[[Image:stockpivot2.jpg|600px]] | [[Image:stockpivot2.jpg|600px]] | ||

Revision as of 18:41, 19 June 2013

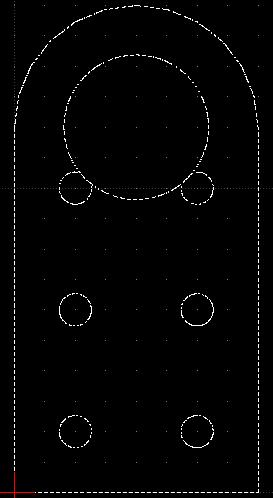

DXF file - File:Stockpivot.dxf

Note: the correct large hole diameter in the above is 4.75", which gives 1/8" room around the DOM for effective welding.

Note: the above is used to generate a CAM file for CNC Torch Table cutting and Laser Cutter modeling - for the pivot plate. In practice, a 4.5" OD DOM with 3" ID is welded inside the 4.875" hole (Mickey Mouse hole) to generate a pivot plate for a 3" shaft. To generate a CAM file for 3D printing, one must consider the 3" tubing and print out a 3" hole, not a 4.875" hole.

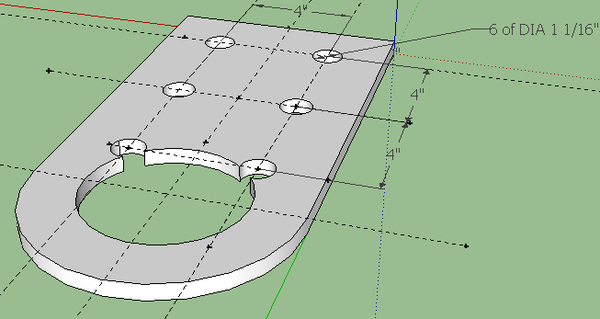

- File:Stock Pivot Plate.skp

- File:Stock Bonding Plate 8 inches x 16 inches.skp

- File:Stock Spacer Plate 8 inches x 8 inches.skp

Notes

This is an official file release with dimensions. Current as of May 17, 2013. Newer versions will be uploaded here.

We can then print these out according to the Ultimaker Post on Using Sketchup for 3D Printing.