Power Cube v17.08: Difference between revisions

No edit summary |

|||

| (13 intermediate revisions by 3 users not shown) | |||

| Line 1: | Line 1: | ||

=Image= | |||

<html><iframe src="https://www.facebook.com/plugins/post.php?href=https%3A%2F%2Fwww.facebook.com%2Fmarcin.jakubowski.378%2Fposts%2F10212113959861414&width=500" width="500" height="582" style="border:none;overflow:hidden" scrolling="no" frameborder="0" allowTransparency="true"></iframe></html> | |||

=Development Template= | |||

<html><iframe src="https://docs.google.com/spreadsheets/d/e/2PACX-1vRwKVP-LpQoNqqB8L3F6H5JOZnOwYkKXXjSXzL671DPkGhJamz0_PNgbNsONMj6Y9DGBeN_vos9s6hT/pubhtml?widget=true&headers=false" height=500 width=500></iframe></html> | |||

[https://docs.google.com/spreadsheets/d/1QcCknOFmX6KMrJjAiLlcJDOaPHEohe9zzWp5ITba6UY/edit#gid=1 edit] | |||

=Visual BOM= | =Visual BOM= | ||

<html><iframe src="https://docs.google.com/presentation/d/1_0upal4AxXcXTAwsGRlZ_-dmfgahoYbuk7uQ7T5mI3E/embed?start=false&loop=false&delayms=3000" frameborder="0" width="480" height="299" allowfullscreen="true" mozallowfullscreen="true" webkitallowfullscreen="true"></iframe></html> | <html><iframe src="https://docs.google.com/presentation/d/1_0upal4AxXcXTAwsGRlZ_-dmfgahoYbuk7uQ7T5mI3E/embed?start=false&loop=false&delayms=3000" frameborder="0" width="480" height="299" allowfullscreen="true" mozallowfullscreen="true" webkitallowfullscreen="true"></iframe></html> | ||

| Line 24: | Line 32: | ||

=BOM= | =BOM= | ||

Other choices: | |||

*12 gpm hydraulic pump - [https://www.ebay.com/sch/i.html?_odkw=.77+cu+in+hydraulic+pump&_osacat=11773&_from=R40&_trksid=p2045573.m570.l1313.TR0.TRC0.H0.X.77+cu+in+gear+hydraulic+pump.TRS0&_nkw=.77+cu+in+gear+hydraulic+pump&_sacat=11773] | |||

<html><iframe src="https://docs.google.com/spreadsheets/d/1gSEDpCuw396kT4vpgTbN5oE7AvCyfc5D_9iEDvg9U5c/pubhtml?widget=true&headers=false" height=500 width=900></iframe></html> | <html><iframe src="https://docs.google.com/spreadsheets/d/1gSEDpCuw396kT4vpgTbN5oE7AvCyfc5D_9iEDvg9U5c/pubhtml?widget=true&headers=false" height=500 width=900></iframe></html> | ||

| Line 35: | Line 46: | ||

=Part Library - CAD Modules= | =Part Library - CAD Modules= | ||

==Master File== | ==Master File== | ||

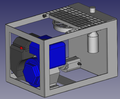

[[File:PC1708_Master.fcstd]] | <gallery perrow=6> | ||

File:Power Cube v17.08.png|[[File:PC1708_Master.fcstd]] | |||

</gallery> | |||

==Frame module== | ==Frame module== | ||

| Line 47: | Line 60: | ||

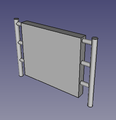

File:PC_1708_Frame_common_sides.png|[[File:PC_1708_Frame_common_sides.fcstd]] - [[File:PC_1708_Frame_common_sides.dxf]] | File:PC_1708_Frame_common_sides.png|[[File:PC_1708_Frame_common_sides.fcstd]] - [[File:PC_1708_Frame_common_sides.dxf]] | ||

File:PC_1708_Frame_top_side.png|[[File:PC_1708_Frame_top_side.fcstd]] - [[File:PC_1708_Frame_top_side.dxf]] | File:PC_1708_Frame_top_side.png|[[File:PC_1708_Frame_top_side.fcstd]] - [[File:PC_1708_Frame_top_side.dxf]] | ||

File:PC_1708_Frame_bottom_side.png|[[File:PC_1708_Frame_bottom_side.fcstd]] - [[File:PC_1708_Frame_bottom_side.dxf]] | |||

</gallery> | </gallery> | ||

| Line 63: | Line 77: | ||

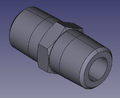

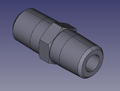

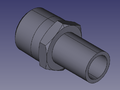

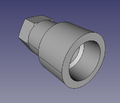

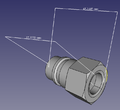

File:1 2 to 3 4 NPT HexNipple.png|[[File:1 2 to 3 4 NPT HexNipple.FCStd]] | File:1 2 to 3 4 NPT HexNipple.png|[[File:1 2 to 3 4 NPT HexNipple.FCStd]] | ||

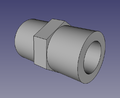

File:3 4 quick coupler female img.png|[[File:3 4 quick coupler female.FCStd]] | File:3 4 quick coupler female img.png|[[File:3 4 quick coupler female.FCStd]] | ||

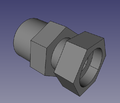

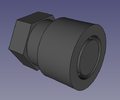

File:3 4 quick coupler male img.png |[[File:3 4 quick coupler Male.FCStd]] | |||

</gallery> | </gallery> | ||

| Line 70: | Line 86: | ||

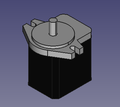

File:PC_1708_engine.jpg|[[File:Xp16hp.FCStd]] | File:PC_1708_engine.jpg|[[File:Xp16hp.FCStd]] | ||

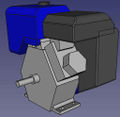

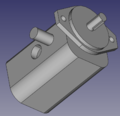

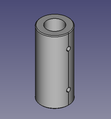

File:Hydraulic Pump.png|[[File:Hydraulic Pump.fcstd]] | File:Hydraulic Pump.png|[[File:Hydraulic Pump.fcstd]] | ||

File: | File:Two stage hydraulic pump.png|[[File:2 Stage Hydraulic Pump.fcstd]] | ||

File:PC_1708_coupler.png|[[File:PC_1708_coupler.fcstd]] | File:PC_1708_coupler.png|[[File:PC_1708_coupler.fcstd]] | ||

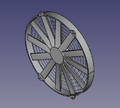

File:PC_1708_cooler.png|[[File:PC_1708_cooler.fcstd]] | File:PC_1708_cooler.png|[[File:PC_1708_cooler.fcstd]] | ||

| Line 123: | Line 139: | ||

*18hp, | *18hp, | ||

*Log splitter pump - [http://www.ebay.com/itm/16-GPM-Hydraulic-Log-Splitter-Pump-2-Stage-Hi-Lo-Gear-Pump-Logsplitter-NEW-/271448842407] - only 8 hp for 13/3 gpm 650/2500 PSI | *Log splitter pump - [http://www.ebay.com/itm/16-GPM-Hydraulic-Log-Splitter-Pump-2-Stage-Hi-Lo-Gear-Pump-Logsplitter-NEW-/271448842407] - only 8 hp for 13/3 gpm 650/2500 PSI | ||

=Data Collection= | |||

*One of starter switch attachment bolts broke off | |||

*Fuel tank is too hard to fill with fan on top of power cube | |||

*Pull cord got tied up inside pull cord case | |||

=Future Quality Control Learnings - verify bolt tightness on engine for all attachments | |||

=Future Work= | |||

*Verification of fuel tank and engine attachments longevity - fuel tank or starter switch breaking off from vibration | |||

*Open source scalable engine with throttle control, gasifier-based | |||

=Links= | =Links= | ||

| Line 128: | Line 154: | ||

*[[Hydraulic Cooler Sizing]] | *[[Hydraulic Cooler Sizing]] | ||

*[[Hydraulic Hose Sizing]] | *[[Hydraulic Hose Sizing]] | ||

*[[Power Cube Library]] | |||

[[Category:Power_Cube]] | [[Category:Power_Cube]] | ||

Latest revision as of 18:51, 26 May 2018

Image

Development Template

Visual BOM

Design Sprints

August 19, 2017

Master CAD Checklist

August 5, 2017

BOM

Other choices:

- 12 gpm hydraulic pump - [2]

Hydraulics

Part Library - CAD Modules

Master File

Frame module

- PC 1708 Frame top side.png

- PC 1708 Frame bottom side.png

Frame Fittings

See the ISO 7241-1 A for hydraulic couplers [3]

Fittings for frame and pump are: 3/4" for hex nip, 1" for hose barb. The ones below are 1/2" and 3/4" barb.

Other Parts

- File:PC 1708 engine.fcstd

- File:PC 1708 enginemount.fcstd

- File:PC 1708 reservoir.fcstd

- File:PC 1708 battery.fcstd

Concept

In order to make the Power Cube much more accessible, we can use a smaller engine - 18 hp - which is approximately 1/3 the effective cost of a 27 HP engine. This would allow us to make smaller machines possible, such as an 18hp walk-behind tractor. The lower cost of the 18hp option allows for wider replicability, and may allow operation without a hydraulic cooler in some applications - reducing cost and complexity significantly. Several major improvements include:

- Design for stable operation with biomass charcoal pellets to move in the direction of renewable energy biofuels that are 10x as efficient as liquid biofuels to produce

- Design for modularity - allowing for interchangeable hydraulic pumps. To date, we have not been using design-for-interchange (completely modular hydraulic pumps) due to the complexity of pump-to-motor coupling. By creating a smart coupling interface, hydraulic pump modularity is feasible, and is the next logical step. This would allow use of the Power Cube

- Simplified frame CNC cut from metal sheet, as opposed to angle, as developed for D3D and as was discovered is easier to fabricate. With 13 IPM Welding Travel Speed - a frame can be laid up quickly and welded 24", 12 sides - in 1/2 hour. That is quicker than the standard power cube with angle, where most of the time was spent in setup and squaring. Squaring is automatic in the next case.

- Material waste could be significant, but not if each side is cut in 2 pieces, so that 12 frame pieces are first welded into 6 sides, then the assembly is welded into the finished product. This moves steel sheet use efficiency from 30% to about 90% efficient for 2' frames.

- Focus on even easier access to parts.

- Remote throttle and starting cable.

- Pull start for use without battery

Minimum viable product:

- Engine

- Pump with quick connects.

No hydraulic cooler, cooler fan, cooler grate and battery. Good for intermittent use, or coninuous below 75F ambient temperature.

Pumping

- 2 stage 28 gpm pump at high flow, 7 gpm at low flow, requires 16 hp of engine drive. [4]

- High flow rate would require a larger 3.5" hydraulic cylinder on the drawer.

- Solenoids are 26.4 - just 6% undersize but that is minimal and the machine runs at this flow only a small fraction of the time.

Thermal Design

- With 18hp, there are conditions under which hydraulic cooling is not necessary.

- Piston efficiency - 90-95% - [5]

- Hydraulic gear pump efficiency - 85%

- Dissipation is 25-40% of input power - 4.5 hp to 7.2 hp

- For 18 hp, 5.4kW of heat dissipation may occur passively through the metal in the Power Cube

- Heat goes into the hydraulic oil at every place in the system where there is a PSI pressure loss due to flow of oil without mechanical work being produced. -[Heat goes into the hydraulic oil at every place in the system where there is a PSI pressure loss due to flow of oil without mechanical work being produced.- [6]

- Every square foot of tube heat exchanger at 50F difference dissipates 2hp of heat - [7]. Same source indicates about 1 hp heat loss from a hydraulic reservoir of 10 sq feet area at a 100F temperature difference.

Products

Parts

- 18hp,

- Log splitter pump - [10] - only 8 hp for 13/3 gpm 650/2500 PSI

Data Collection

- One of starter switch attachment bolts broke off

- Fuel tank is too hard to fill with fan on top of power cube

- Pull cord got tied up inside pull cord case

=Future Quality Control Learnings - verify bolt tightness on engine for all attachments

Future Work

- Verification of fuel tank and engine attachments longevity - fuel tank or starter switch breaking off from vibration

- Open source scalable engine with throttle control, gasifier-based