PVC Pipe and Fittings Library: Difference between revisions

(→Basics) |

|||

| (37 intermediate revisions by 3 users not shown) | |||

| Line 1: | Line 1: | ||

=Basics= | =Basics= | ||

This is a library of all the current PVC Pipe and Fittings that have been made in freecad for OSE. Many fittings can be created using [[ | This is a library of all the current PVC Pipe and Fittings that have been made in freecad for OSE. Many fittings can be created using [[OSE Piping Workbench]]. | ||

= | =Seed Eco-Home 6= | ||

*Plumbing file - [https://drive.google.com/drive/folders/1FtcP-Ljy2xHXry87OtCxtl8WBE7or4A3] | |||

= Pipe dimensions used in literature = | |||

* O.D. - outer diameter. | * O.D. - outer diameter. | ||

* Average I.D. - average inner diameter (why average?). This dimension determines the size of the pipe. | * Average I.D. - average inner diameter (why average?). This dimension determines the size of the pipe. | ||

| Line 26: | Line 12: | ||

* Schedule - determines (indirectly) the thickness of the wall. | * Schedule - determines (indirectly) the thickness of the wall. | ||

= | =Basic Parts= | ||

*1.5" elbow - | |||

*2" coupler - [[File:2inchcoupler.fcstd]] | |||

=Parts Generated Using the OSE Piping Workbench + Other= | |||

= | <gallery perrow=6> | ||

File:3elbow.png |'''3" PVC Elbow'''. Standard height of 4.75" as in [https://www.mcmaster.com/2389K29/]. - size:20kb - FreeCAD -[[File:3"-pvc-elbow.fcstd]], | |||

[[File: | |||

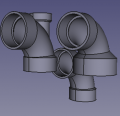

File:toiletparts.png| '''Toilet Parts''' - Includes closet flange, 3" elbow with 2" heel, long 3" elbow - [[File:toiletparts.fcstd]] | |||

File:rotatabletrap.png |'''1.5" rotatable trap''' - FreeCAD -[[File:15rottrap.fcstd]] | |||

[[File: | |||

File:2doublesanteetee.png |'''2" sanitary tee''' - FreeCAD -[[File:2doublesantee.fcstd]] | |||

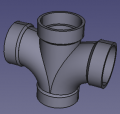

[[File: | File:2doublefixtee.png |'''2" double fixture tee''' - Nibco site - [https://catalog.nibco.com/rfcconfirmation?name=all-categories&xcartid=27675] FreeCAD -[[File:2doublefixtee.fcstd]] | ||

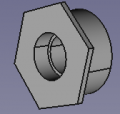

File:3to15bushing.png |'''3" to 1.5" reducer bushing''' - FreeCAD -[[File:3to15bushing.fcstd]] | |||

File:3wye.png |'''3" wye''' - size:80kb - FreeCAD -[[File:3wye.fcstd]] | |||

[[File: | |||

File:345streetbend.png |'''3" 45 degree street elbow''' - size:80kb - FreeCAD -[[File:345streetbend.fcstd]] | |||

File:1FKHDAF.png|'''1.5" 45 degree street elbow''' - size:80kb - FreeCAD -[[File:1545streetbend.fcstd]] | |||

File:15elbow.png |'''1.5" elbow''' - size:30kb - FreeCAD -[[File:15elbow.fcstd]] | |||

File:2tee.png |'''2 inch tee''' - size: 25k - FreeCAD -[[File:2tee.fcstd]] | |||

[[File: | |||

File:create-pipe-cad-screenshot.png |'''SCH40 1" PVC pipe''' - size:5kb - FreeCAD -[[File:pipe-test.fcstd]], | File:create-pipe-cad-screenshot.png |'''SCH40 1" PVC pipe''' - size:5kb - FreeCAD -[[File:pipe-test.fcstd]], | ||

File:create-elbow-cad-screenshot.png |'''Elbow test file.''' Here alpha° is 45°. - size:21kb - FreeCAD -[[File:elbow-test.fcstd]], | File:create-elbow-cad-screenshot.png |'''Elbow test file.''' Here alpha° is 45°. - size:21kb - FreeCAD -[[File:elbow-test.fcstd]], | ||

| Line 130: | Line 53: | ||

=Library of STEP Downloads from McMaster Carr= | =Library of STEP Downloads from McMaster Carr= | ||

Comparable in size to generated parts - except for some parts which are way too heavy. | Comparable in size to generated parts - except for some parts which are way too heavy. | ||

<gallery perrow=6> | <gallery perrow=6> | ||

File:elbow.png |'''1" PVC Elbow''' - size:19kb - FreeCAD -[[File:1"-pvc-elbow.fcstd]], | File:elbow.png |'''1" PVC Elbow''' - size:19kb - FreeCAD -[[File:1"-pvc-elbow.fcstd]], | ||

| Line 147: | Line 72: | ||

File:2"-elbow.jpg |'''2" PVC Elbow''' - size:157kb - FreeCAD -[[File:2"-elbow.fcstd]], | File:2"-elbow.jpg |'''2" PVC Elbow''' - size:157kb - FreeCAD -[[File:2"-elbow.fcstd]], | ||

File:2"-tee. | File:2"-tee.png |'''2" PVC Tee''' -157k - STEP -[https://www.mcmaster.com/#2389k23/=1bcgk5c] - FreeCAD - [[File:2"-pvc-tee.fcstd]] | ||

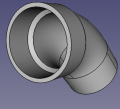

File:2"- | File:2"-elbow-short.png |'''2" PVC Elbow - Short Nonstandard''' - size:4kb - STEP -[https://www.mcmaster.com/#4881k26/=1bcheo0] - FreeCAD - [[File:2"-pvc-tee-short.fcstd]] (file misnamed) | ||

File:2"-3"-bushing.jpg |'''2"-3" bushing''' - size:161kb - STEP -[https://www.mcmaster.com/#2389k53/=1bchs2a] - FreeCAD - [[File:2"-3"-bushing.fcstd]] | File:2"-3"-bushing.jpg |'''2"-3" bushing''' - size:161kb - STEP -[https://www.mcmaster.com/#2389k53/=1bchs2a] - FreeCAD - [[File:2"-3"-bushing.fcstd]] | ||

| Line 159: | Line 84: | ||

</gallery> | </gallery> | ||

= FAQ = | = FAQ = | ||

| Line 210: | Line 89: | ||

* Do we really want to 3D-print pipe fittings? Somehow I have doubt about mechanical properties of the 3D-printed products. | * Do we really want to 3D-print pipe fittings? Somehow I have doubt about mechanical properties of the 3D-printed products. | ||

*: Yes. For high pressure applications - 300 PSI - we would have to be very careful. For low pressure, such as 5 PSI, it's not a problem. Eventually, we want to refine printing techniques where our fittings can do what standard schedule 80 ABS fittings can do. | *: Yes. For high pressure applications - 300 PSI - we would have to be very careful. For low pressure, such as 5 PSI, it's not a problem. Eventually, we want to refine printing techniques where our fittings can do what standard schedule 80 ABS fittings can do. | ||

** Also with things such as part baking/ | ** Also with things such as part baking/[[FDM 3D Print Annealing | annealing]], composite filaments, and SLA or SLS Printers, very durable parts can be made. Granted i agree proper testing, and potentially getting "Listed" or whatever the [[Building Code]] / [[Insurance]] stuff would need | ||

[[Category: Materials]] [[Category: Plumbing]] | |||

Latest revision as of 04:39, 8 September 2025

Basics

This is a library of all the current PVC Pipe and Fittings that have been made in freecad for OSE. Many fittings can be created using OSE Piping Workbench.

Seed Eco-Home 6

- Plumbing file - [8]

Pipe dimensions used in literature

- O.D. - outer diameter.

- Average I.D. - average inner diameter (why average?). This dimension determines the size of the pipe.

- Min. Wall - thickness of the pipe wall.

- Schedule - determines (indirectly) the thickness of the wall.

Basic Parts

- 1.5" elbow -

- 2" coupler - File:2inchcoupler.fcstd

Parts Generated Using the OSE Piping Workbench + Other

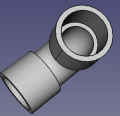

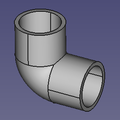

3" PVC Elbow. Standard height of 4.75" as in [1]. - size:20kb - FreeCAD -File:3"-pvc-elbow.fcstd,

Toilet Parts - Includes closet flange, 3" elbow with 2" heel, long 3" elbow - File:Toiletparts.fcstd

1.5" rotatable trap - FreeCAD -File:15rottrap.fcstd

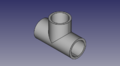

2" sanitary tee - FreeCAD -File:2doublesantee.fcstd

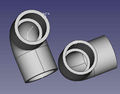

2" double fixture tee - Nibco site - [2] FreeCAD -File:2doublefixtee.fcstd

3" to 1.5" reducer bushing - FreeCAD -File:3to15bushing.fcstd

3" wye - size:80kb - FreeCAD -File:3wye.fcstd

3" 45 degree street elbow - size:80kb - FreeCAD -File:345streetbend.fcstd

1.5" 45 degree street elbow - size:80kb - FreeCAD -File:1545streetbend.fcstd

1.5" elbow - size:30kb - FreeCAD -File:15elbow.fcstd

- 2tee.png

2 inch tee - size: 25k - FreeCAD -File:2tee.fcstd

SCH40 1" PVC pipe - size:5kb - FreeCAD -File:Pipe-test.fcstd,

Elbow test file. Here alpha° is 45°. - size:21kb - FreeCAD -File:Elbow-test.fcstd,

1"-1/2" coupling test file - size:17kb - FreeCAD -File:Coupling-test.fcstd

1"-1/2" bushing - size:21kb - FreeCAD -File:Bushing-test.fcstd

1" tee test file - size:28kb - FreeCAD -File:Tee-test.fcstd

1" cross test file - size:34kb - FreeCAD -File:Cross-test.fcstd

1" outer corner test file - size:30kb - FreeCAD -File:Corner-test.fcstd

Library of STEP Downloads from McMaster Carr

Comparable in size to generated parts - except for some parts which are way too heavy.

1" PVC Elbow - size:19kb - FreeCAD -File:1"-pvc-elbow.fcstd,

1" PVC Tee - size:25kb - FreeCAD -File:1"-pvc-tee.fcstd,

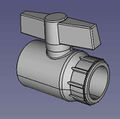

1" PVC Valve - size:500kb - FreeCAD -File:1"-pvc-valve.fcstd,

1"-3/4" PVC Bushing - size:13kb - FreeCAD -File:1"-34"-reducer.fcstd,

1" PVC Cross - size:13kb - FreeCAD -File:1"-cross.fcstd,

2" PVC Elbow - size:157kb - FreeCAD -File:2"-elbow.fcstd,

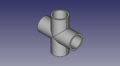

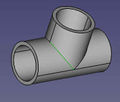

2" PVC Tee -157k - STEP -[3] - FreeCAD - File:2"-pvc-tee.fcstd

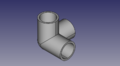

2" PVC Elbow - Short Nonstandard - size:4kb - STEP -[4] - FreeCAD - File:2"-pvc-tee-short.fcstd (file misnamed)

- 2"-3"-bushing.jpg

2"-3" bushing - size:161kb - STEP -[5] - FreeCAD - File:2"-3"-bushing.fcstd

- 3"-2"-reducer.jpg

2"-3" reducer. Note difference between a reducer and a bushing (last one) - size:161kb - Menards -[6] - FreeCAD - File:3"-2"-reducer.fcstd

- 3"-2"-reducer.jpg

2"-1" reducer. - size:10kb - STEP -[7] - FreeCAD - File:2"-1"-PVC-reducer.fcstd

FAQ

- Do we really want to 3D-print pipe fittings? Somehow I have doubt about mechanical properties of the 3D-printed products.

- Yes. For high pressure applications - 300 PSI - we would have to be very careful. For low pressure, such as 5 PSI, it's not a problem. Eventually, we want to refine printing techniques where our fittings can do what standard schedule 80 ABS fittings can do.

- Also with things such as part baking/ annealing, composite filaments, and SLA or SLS Printers, very durable parts can be made. Granted i agree proper testing, and potentially getting "Listed" or whatever the Building Code / Insurance stuff would need

![3" PVC Elbow. Standard height of 4.75" as in [1]. - size:20kb - FreeCAD -File:3"-pvc-elbow.fcstd,](/images/thumb/0/04/3elbow.png/120px-3elbow.png)

![2" double fixture tee - Nibco site - [2] FreeCAD -File:2doublefixtee.fcstd](/images/thumb/c/c4/2doublefixtee.png/120px-2doublefixtee.png)

![2" PVC Tee -157k - STEP -[3] - FreeCAD - File:2"-pvc-tee.fcstd](/images/thumb/8/8d/2%22-tee.png/119px-2%22-tee.png)

![2" PVC Elbow - Short Nonstandard - size:4kb - STEP -[4] - FreeCAD - File:2"-pvc-tee-short.fcstd (file misnamed)](/images/thumb/4/4d/2%22-elbow-short.png/120px-2%22-elbow-short.png)