User:Dorkmo/Ideas/TorchTable: Difference between revisions

< User:Dorkmo | Ideas

Jump to navigation

Jump to search

(→BOM) |

(→BOM) |

||

| (13 intermediate revisions by the same user not shown) | |||

| Line 15: | Line 15: | ||

*Stepper Driver | *Stepper Driver | ||

**Stepoko? [https://www.sparkfun.com/products/13899 sparkfun] | **Stepoko? [https://www.sparkfun.com/products/13899 sparkfun] | ||

**AutoDriver | **AutoDriver - [https://github.com/grbl/grbl/issues/1005#issuecomment-222648386 nope] [https://www.sparkfun.com/products/13752 sparkfun] | ||

**Ramps [https://ultimachine.com/collections/electronics/products/ramps-pre-assembled-kit-complete ultimachine] | |||

**TB6600 - 4Amp [https://www.robotshop.com/en/tb6600-stepper-motor-driver.html robotshop] | |||

*24V 300W Power Supply [https://www.alliedelec.com/altech-corp-psa-36024/70236410/ Allied Elec] | *24V 300W Power Supply [https://www.alliedelec.com/altech-corp-psa-36024/70236410/ Allied Elec] | ||

*Belt - GT 2mm pitch x 6mm wide [http://www.biedlers-belts.com/gates-ll2mr06-belt.html Biedlers Belts] | |||

*Sprocket - GT2 2mm pitch x 6mm wide x 20 tooth [https://e3d-online.com/gt2-pulley-20-tooth E3D store] [https://wiki.e3d-online.com/images/e/e7/20_tooth_pulley_PUBLIC.pdf 2D Drawing] | |||

*M3 socket cap screw - length may vary | |||

*M3 high collar lock washer | |||

=Design= | =Design= | ||

| Line 25: | Line 31: | ||

*Sketchup basic idea - [https://github.com/dorkmo/OSE-TorchTable-dorkmo-201808 github] | *Sketchup basic idea - [https://github.com/dorkmo/OSE-TorchTable-dorkmo-201808 github] | ||

=Notes= | |||

*Mcmaster doesnt seem to carry GT belts? but the have other sizes. | |||

**GT seems to be popular size with 3D printers for some reason | |||

***https://reprap.org/wiki/Choosing_Belts_and_Pulleys | |||

*Perhaps a wider belt should be investigated for higher torque | |||

=See Also= | =See Also= | ||

*[[Polemidis_Log#Sat_Aug_26th_2017]] | *[[Polemidis_Log#Sat_Aug_26th_2017]] | ||

Latest revision as of 21:39, 7 October 2018

Goals

- Torch table using standard flat bar and angle iron for structural support. borrowing electronics from D3D CNC Torch Table.

- Possibly use multiple ball bearing rollers with spring support to tolerate debris on bar surface

- 3D printed mounting points that minimize drilling/welding

BOM

- 1/4" x 6" x 9' Flat Bar - discount steel

- 1-1/2" x 1-1/2" x 1/8" x 9' Angle - discount steel

- R6 Ball Bearing - grainger

- Stepper motor NEMA 17 - reprap page

- Stepper Driver

- Stepoko? sparkfun

- AutoDriver - nope sparkfun

- Ramps ultimachine

- TB6600 - 4Amp robotshop

- 24V 300W Power Supply Allied Elec

- Belt - GT 2mm pitch x 6mm wide Biedlers Belts

- Sprocket - GT2 2mm pitch x 6mm wide x 20 tooth E3D store 2D Drawing

- M3 socket cap screw - length may vary

- M3 high collar lock washer

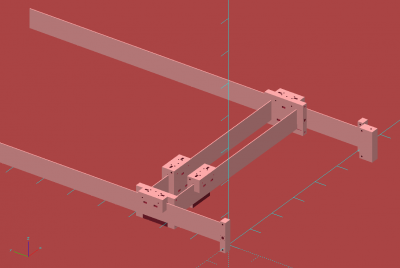

Design

CAD

- Sketchup basic idea - github

Notes

- Mcmaster doesnt seem to carry GT belts? but the have other sizes.

- GT seems to be popular size with 3D printers for some reason

- Perhaps a wider belt should be investigated for higher torque