User:Dorkmo/Builds/CircularKnitic: Difference between revisions

< User:Dorkmo | Builds

Jump to navigation

Jump to search

| (34 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

Attempting to build a [[OSE CircularKnitic v18.03]] machine. Updating the design files along the way. | Attempting to build a [[OSE CircularKnitic v18.03]] machine. Updating the design files along the way. | ||

=BOM= | |||

===Tools=== | |||

*5.5 end wrench - [https://www.grainger.com/product/MOODY-TOOL-5-5mm-6LEZ6 grainger] | |||

*2.5 Hex driver L - [https://www.grainger.com/product/EKLIND-L-Shape-Ball-End-Hex-Key-with-4CR82 grainger] | |||

*2.5 Hex screw driver - [https://www.grainger.com/product/WIHA-TOOLS-2-5mm-Hex-Insulated-Screwdriver-53KF02 grainger] | |||

===Nuts & Bolts=== | |||

*M3 x 25 - [https://www.fastenal.com/products/details/86007?r=~%7Ccategoryl1:%22600000%20Fasteners%22%7C~%20~%7Ccategoryl2:%22600039%20Sockets%22%7C~%20~%7Ccategoryl3:%22600040%20Socket%20Cap%20Screws%22%7C~%20~%7Csattr01:%5EMetric$%7C~%20~%7Cmanufacturer:%5EHOLO-KROME Fastenal] | |||

*M3 x 20 - [https://www.fastenal.com/products/details/86006?r=~%7Ccategoryl1:%22600000%20Fasteners%22%7C~%20~%7Ccategoryl2:%22600039%20Sockets%22%7C~%20~%7Ccategoryl3:%22600040%20Socket%20Cap%20Screws%22%7C~%20~%7Csattr01:%5EMetric$%7C~%20~%7Cmanufacturer:%5EHOLO-KROME Fastenal] | |||

*M3 x 12 - [https://www.fastenal.com/products/details/0137182?r=~%7Ccategoryl1:%22600000%20Fasteners%22%7C~%20~%7Ccategoryl2:%22600039%20Sockets%22%7C~%20~%7Ccategoryl3:%22600040%20Socket%20Cap%20Screws%22%7C~%20~%7Csattr01:%5EMetric$%7C~%20~%7Cmanufacturer:%5EHOLO-KROME Fastenal] | |||

*M3 x 10 - [https://www.fastenal.com/products/details/86003?r=~%7Ccategoryl1:%22600000%20Fasteners%22%7C~%20~%7Ccategoryl2:%22600039%20Sockets%22%7C~%20~%7Ccategoryl3:%22600040%20Socket%20Cap%20Screws%22%7C~%20~%7Csattr01:%5EMetric$%7C~%20~%7Cmanufacturer:%5EHOLO-KROME Fastenal] | |||

*Square Nuts M3 - [https://www.fastenal.com/products/details/0161907?r=~%7Ccategoryl1:%22600000%20Fasteners%22%7C~%20~%7Ccategoryl2:%22600072%20Nuts%22%7C~%20~%7Ccategoryl3:%22600086%20Square%20Nuts%22%7C~%20~%7Csattr01:%5EMetric$%7C~ Fastenal] | |||

*M2 x 12 - [https://www.fastenal.com/products/details/0137182?r=~%7Ccategoryl1:%22600000%20Fasteners%22%7C~%20~%7Ccategoryl2:%22600039%20Sockets%22%7C~%20~%7Ccategoryl3:%22600040%20Socket%20Cap%20Screws%22%7C~%20~%7Csattr01:%5EMetric$%7C~%20~%7Csattr04:%5EM2-0.4$%7C~%20~%7Cmanufacturer:%5EHOLO-KROME Fastenal] | |||

*M2 Nuts | |||

===Bearings=== | |||

*NTN Bearing [https://us.misumi-ec.com/vona2/detail/221000058378/?CategorySpec=00000044000%3a%3aa%09unitType%3a%3a1%0900000044017%3a%3amig00000001454977%0900000043985%3a%3amig00000001455783&Inch=0&curSearch=%7b%22field%22%3a%22%40search%22%2c%22seriesCode%22%3a%22221000058378%22%2c%22innerCode%22%3a%22%22%2c%22sort%22%3a1%2c%22specSortFlag%22%3a0%2c%22allSpecFlag%22%3a0%2c%22page%22%3a1%2c%22pageSize%22%3a%2260%22%2c%2200000044015%22%3a%22a%22%2c%2200000044035%22%3a%22b%22%2c%2200000044031%22%3a%22b%22%2c%2200000043966%22%3a%22a%22%2c%2200000044021%22%3a%22mig00000001454974%22%2c%2200000043967%22%3a%22mig00000001455792%22%2c%2200000044024%22%3a%22a%22%2c%2200000043984%22%3a%22a%22%2c%2200000044007%22%3a%22b%22%2c%2200000044039%22%3a%22b%22%2c%2200000044000%22%3a%22a%22%2c%2200000044017%22%3a%22mig00000001454977%22%2c%2200000043985%22%3a%22mig00000001455783%22%2c%22fixedInfo%22%3a%22MDM000038605022210000583781%7c18%22%7d&Tab=codeList MiSUMi] or NSK Bearing [https://us.misumi-ec.com/vona2/detail/221000531116/?HissuCode=MR105 MiSUMi] | |||

===Electronics=== | |||

*https://www.mouser.com/ProductDetail/Cosel/PBA75F-12-N?qs=7%252b9h8EK%252bkyuJ0545jeaWQA%3D%3D | |||

**https://www.alliedelec.com/product/altech-corp/ps-7512/70075527/ | |||

*https://store.arduino.cc/usa/arduino-motor-shield-rev3 | |||

**https://www.mouser.com/ProductDetail/Arduino/A000079?qs=sGAEpiMZZMsyTxkJnMM1W05qedAfM53YGil6u%2F3w8qE%3D | |||

*https://store.arduino.cc/usa/arduino-uno-rev3 | |||

Stepper - PKP243D08A2 - [https://catalog.orientalmotor.com/item/42mm-pkp-series-2-phase-bipolar-stepper-motors/42mm-pkp-series-2-phase-bipolar-stepper-motors/pkp243d08a2?__hstc=62166835.a4abea4a98a288534502f90ff637ff22.1551402315584.1551402315584.1551402315584.1&__hssc=62166835.9.1551402315584&__hsfp=1451263049 Oriental Motor] | |||

=Build Log= | =Build Log= | ||

===March 23, 2019=== | |||

*changed how the aluminum angle is mounted to the mountain | |||

*incrased the thickness of the p4 yard holder base | |||

*still trying to get the end of the groove to transition smoothly to pPspace | |||

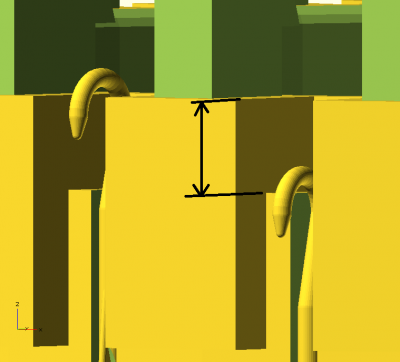

[[Image:CKp4-tweak1.png|400px]] | |||

===March 10, 2019=== | |||

*Updating [[OSE_CircularKnitic_v18.03#To_Do]] list based on notes from this build | |||

*Going to start build of larger diameter machine with these updates | |||

**Documenting here [[User:Dorkmo/Builds/CircularKnitic-Grande]] | |||

===March 9, 2019=== | |||

*think it might be good to use Flat socket cap screws so that the the head doesnt protrude and block the removal of plates | |||

**https://www.fastenal.com/products/details/86258?r=~%7Ccategoryl1:%22600000%20Fasteners%22%7C~%20~%7Ccategoryl2:%22600039%20Sockets%22%7C~%20~%7Ccategoryl3:%22600042%20Flat%20Socket%20Cap%20Screws%22%7C~%20~%7Csattr02:%5EM2-0.4$%7C~%20~%7Csattr02:%5EM3-0.5$%7C~%20~%7Cmanufacturer:%5EHOLO-KROME[REG]$%7C~ | |||

===March 3, 2019=== | |||

*Noticed that the mountain shelf didnt seem to fit perfectly | |||

**measured cut plates from sculpteo, theyre measure at about 0.134inch / 3.40mm. A little bit thicker than 1/8" (0.125)inch. | |||

**i think this may have caused a little bit of the seperation under the mountain | |||

**by sandwiching the mountain wings i think this will make it more tolerant of imperfect measurements of plates | |||

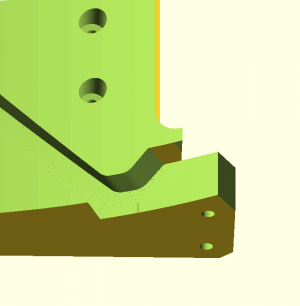

[[Image:CK20190303-shelfchange.png|300px]] | |||

===March 2, 2019=== | |||

*I had these motors for something else and decided to use them, but i think they might be overkill | |||

*:[https://catalog.orientalmotor.com/item/2-phase-bipolar-stepper-motors/42mm-pkp-series-2-phase-bipolar-stepper-motors/pkp246d15a2 PKP246D15A2] | |||

**Arduino Motor Shield seems to be overheating when connected to one, acting sporadically | |||

**Steppers are rated at 1.5amp per phase, Motor Shield rated at 2amp per channel, but no active cooling | |||

**As a stopgap solution i stacked 4 Motor Shields, and pointed a fan at the stack. (Sounds like competitive CPU Overclocking, but for motor sheilds, lol) | |||

***ran 1 phase off of each of the two bi-polar motors to its own motor shield | |||

**Seems to be able to run continously now | |||

*used paperclips for weighing down threads | |||

**bent a paperclip in half, creating a hook on each end | |||

**hang smaller side off of thread | |||

**connected two of the paperclips to an unaltered paperclp, then added about 4 more. | |||

**connected all of the bottom clips to a keychain ring | |||

**placed a plastic bowl in the center, filled a plastic bag with water, placed in bowl | |||

*While running, it seems that occasionally a loop will not come up to the top of the needle as it moves down | |||

**This causes the loop to prevent the latch from opening, then it seems to skip the next loop | |||

**Not sure if this is being caused by the loose fit of c2 and c3 (large c2gap), or that p4 needs to be adjusted | |||

***in turn if p4 needs to adjust i think the travel of the needle pushdown will also need to inscrease | |||

**Or perhaps more tension before feeder thread? | |||

**In the video below you can see a few places where the output looks pinched | |||

<html><iframe width="560" height="315" src="https://www.youtube.com/embed/I-umY3QzAnA" frameborder="0" allow="accelerometer; autoplay; encrypted-media; gyroscope; picture-in-picture" allowfullscreen></iframe></html> | |||

===February 28, 2019=== | |||

*Got steppers running | |||

**using the arduino motor driver, i dont think it can microstep so its a bit jerky it seems | |||

**probably could slow down a little | |||

**also noticing that the gap between the cut plates and the wall could be smaller | |||

*Casted on for the first time | |||

**did pretty good for a few rounds but started to miss a few needles | |||

**the thread bunched up on the yarn holders, i think more weight is needed to pull down | |||

*tried using a series of paperclips to attach weights. used a cordless drill as a weight | |||

**seemed to work, but diameter seems to shrink as it lowers, need to maintain width | |||

**will test different layouts | |||

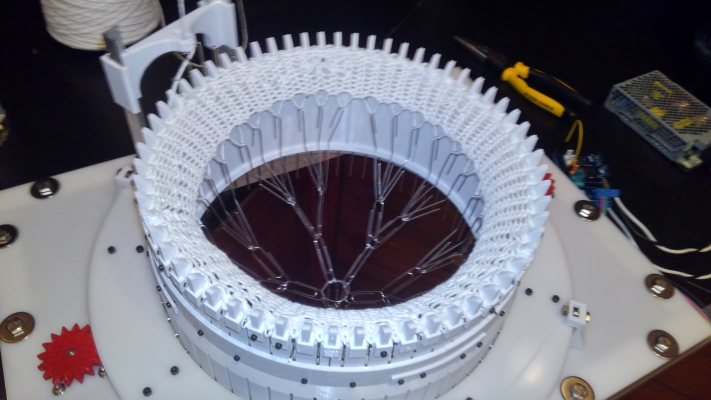

[[Image:CKpics-20190228.png]] | |||

===February 23, 2019=== | |||

*Got most of the mechanical parts assembled | |||

*Still need to build a weight and paperclip system to pull down | |||

*ended up using 1x1" square aluminum tubing for base support, seems pretty good | |||

*Need to figure out stepper driver setup | |||

**Using arduino and a sparkfun AutoDriver | |||

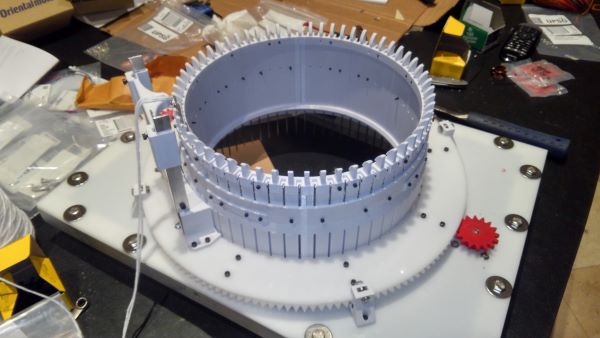

[[Image:CK-pics.JPG]] | |||

===February 19, 2019=== | |||

*Got parts in from 3Dhubs and Sculpteo. Everything looks good. | |||

*Should get bearings and bolts later this week. | |||

*Discovered an obvious bug with the current design. | |||

**Needle unable to slide easily into slots | |||

**Thankfully can twist into position on this print. Will use. But also tweak design for future prints. | |||

**Need to raise/trim the top of groove on p3, or cut into base a little bit | |||

[[Image:CK-Bug-Needlebutt.png|400px]] | |||

===February 15, 2019=== | ===February 15, 2019=== | ||

Latest revision as of 03:46, 24 March 2019

Attempting to build a OSE CircularKnitic v18.03 machine. Updating the design files along the way.

BOM

Tools

Nuts & Bolts

- M3 x 25 - Fastenal

- M3 x 20 - Fastenal

- M3 x 12 - Fastenal

- M3 x 10 - Fastenal

- Square Nuts M3 - Fastenal

- M2 x 12 - Fastenal

- M2 Nuts

Bearings

Electronics

- https://www.mouser.com/ProductDetail/Cosel/PBA75F-12-N?qs=7%252b9h8EK%252bkyuJ0545jeaWQA%3D%3D

- https://store.arduino.cc/usa/arduino-motor-shield-rev3

- https://store.arduino.cc/usa/arduino-uno-rev3

Stepper - PKP243D08A2 - Oriental Motor

Build Log

March 23, 2019

- changed how the aluminum angle is mounted to the mountain

- incrased the thickness of the p4 yard holder base

- still trying to get the end of the groove to transition smoothly to pPspace

March 10, 2019

- Updating OSE_CircularKnitic_v18.03#To_Do list based on notes from this build

- Going to start build of larger diameter machine with these updates

- Documenting here User:Dorkmo/Builds/CircularKnitic-Grande

March 9, 2019

- think it might be good to use Flat socket cap screws so that the the head doesnt protrude and block the removal of plates

March 3, 2019

- Noticed that the mountain shelf didnt seem to fit perfectly

- measured cut plates from sculpteo, theyre measure at about 0.134inch / 3.40mm. A little bit thicker than 1/8" (0.125)inch.

- i think this may have caused a little bit of the seperation under the mountain

- by sandwiching the mountain wings i think this will make it more tolerant of imperfect measurements of plates

March 2, 2019

- I had these motors for something else and decided to use them, but i think they might be overkill

- Arduino Motor Shield seems to be overheating when connected to one, acting sporadically

- Steppers are rated at 1.5amp per phase, Motor Shield rated at 2amp per channel, but no active cooling

- As a stopgap solution i stacked 4 Motor Shields, and pointed a fan at the stack. (Sounds like competitive CPU Overclocking, but for motor sheilds, lol)

- ran 1 phase off of each of the two bi-polar motors to its own motor shield

- Seems to be able to run continously now

- used paperclips for weighing down threads

- bent a paperclip in half, creating a hook on each end

- hang smaller side off of thread

- connected two of the paperclips to an unaltered paperclp, then added about 4 more.

- connected all of the bottom clips to a keychain ring

- placed a plastic bowl in the center, filled a plastic bag with water, placed in bowl

- While running, it seems that occasionally a loop will not come up to the top of the needle as it moves down

- This causes the loop to prevent the latch from opening, then it seems to skip the next loop

- Not sure if this is being caused by the loose fit of c2 and c3 (large c2gap), or that p4 needs to be adjusted

- in turn if p4 needs to adjust i think the travel of the needle pushdown will also need to inscrease

- Or perhaps more tension before feeder thread?

- In the video below you can see a few places where the output looks pinched

February 28, 2019

- Got steppers running

- using the arduino motor driver, i dont think it can microstep so its a bit jerky it seems

- probably could slow down a little

- also noticing that the gap between the cut plates and the wall could be smaller

- Casted on for the first time

- did pretty good for a few rounds but started to miss a few needles

- the thread bunched up on the yarn holders, i think more weight is needed to pull down

- tried using a series of paperclips to attach weights. used a cordless drill as a weight

- seemed to work, but diameter seems to shrink as it lowers, need to maintain width

- will test different layouts

February 23, 2019

- Got most of the mechanical parts assembled

- Still need to build a weight and paperclip system to pull down

- ended up using 1x1" square aluminum tubing for base support, seems pretty good

- Need to figure out stepper driver setup

- Using arduino and a sparkfun AutoDriver

February 19, 2019

- Got parts in from 3Dhubs and Sculpteo. Everything looks good.

- Should get bearings and bolts later this week.

- Discovered an obvious bug with the current design.

- Needle unable to slide easily into slots

- Thankfully can twist into position on this print. Will use. But also tweak design for future prints.

- Need to raise/trim the top of groove on p3, or cut into base a little bit

February 15, 2019

- I mistakenly assumed 5x10x4 metric bearings (MR105) would be easy to find

- I already ordered 3D prints so im married to this size for now

- McMaster only carries expensive stainless version of this size

- Some available on amazon but they all seem dodgy, will save for last resort

- Will contact local bearing shop to see if they can order in

- Went ahead and ordered from MiSUMi

February 10, 2019

- Ordred 3D printed parts from 3Dhubs.com

- very little control over print settings

- Possible that parts will have sizing issues without being able to measure between prints

Febraury 9, 2019

- ordered laser cut parts from Sculpteo.com

- Their maximum thickness available is 1/8" or ~3.175mm.

- This is thinner than the original machine's 5mm and 6mm parts

- Taking a chance and hoping this wont be a problem structurally

January 2019

- tweaked variables so that laser cut parts will fit within 380mm width.

- This seems to be an industry standard for smaller plastic stock sheets?

December 2018

- Got design in working order, begin cleaning up issues/bugs

November 2018

- Contacted Mar from CirularKnitic

- Retstarted design work

May 27, 2018

- going to make the outside diameter for p3 about 1,000mm so that it will fit within 4 feet.

- The "Mountain" part didnt like being generated for a largr diameter machine. going to have to go back a tweak a couple things.

- looking at polycarbonate prices, seems steel is almost the same price per volume.

- will probably be easier to find a steel plate laser cutter machine shop

- thinking im going to use steel where they used polycarbonate sheets.

May 22, 2018

- getting close to finishing up variable formulas that need to be calculated based on needle dimensions

- part3 "p3" rendering incorrectly.

- diameter not expanding to accomidate more needles

May 1, 2018

- Recieved needles in the mail

- used digital calipers to take measurements

- Documented here OSE_CircularKnitic_v18.03#CKneedleVars-KH260.scad

April 2018

ordered some needles from this hong kong website http://shop.sckmcl.com.hk/product_info.php?products_id=136

- KH260 for Brother Knitting Machine Main Bed Needles 413426001

- might try using 360 needles. sounds like a nice number to shoot for.